Low-cost heat pump water heater

a low-cost, water heater technology, applied in heat pumps, refrigerating machines, lighting and heating apparatus, etc., can solve the problems of inactivity of desuperheaters, and inability to meet the water heating load in the house, etc., to achieve optimal and efficient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

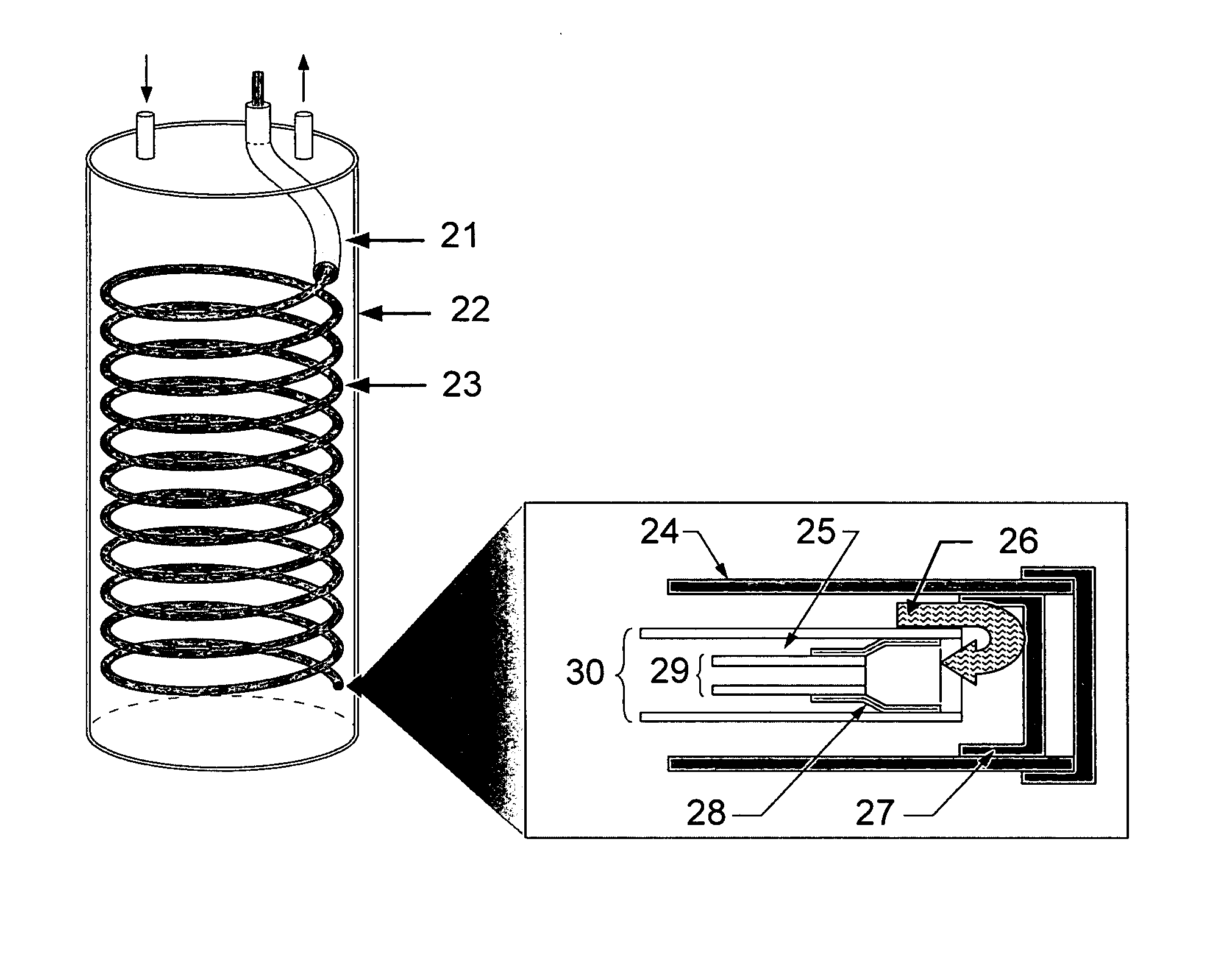

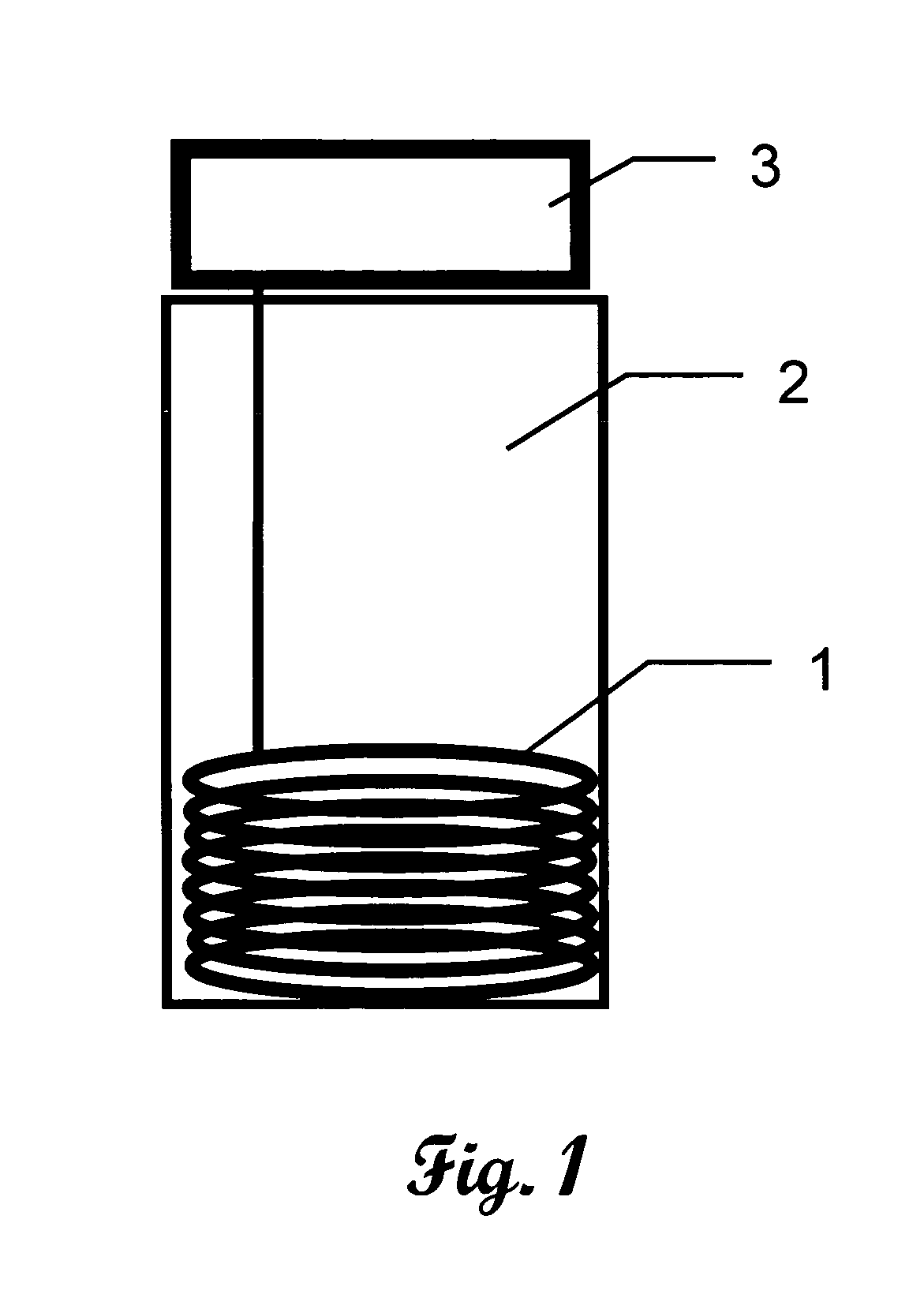

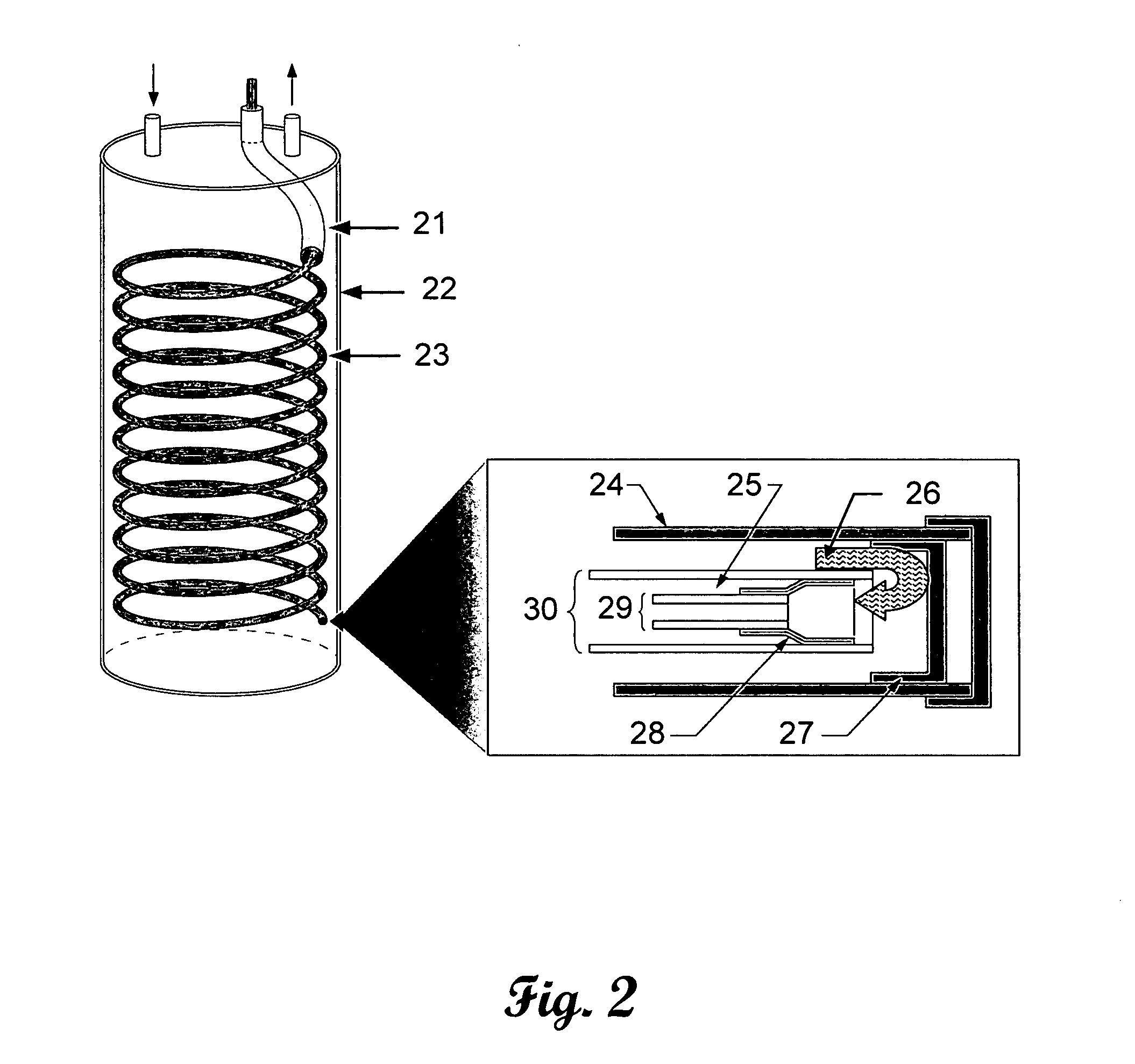

[0022] One of the biggest challenges to be met is finding a way to install a large surface area condenser into the conventional tank through one of the small pipe fittings (¾″ FPT) that is already on the top of all water heaters. This is somewhat akin to building a ship in a bottle with a small neck. The invention overcomes this problem by installing a short, geometric twisted sleeve through the small diameter top fitting in the top of the tank, and then pushing a long condenser assembly through the open sleeve. As the linear condenser is pushed through the sleeve, it forms itself into a helix inside the tank. The radius, pitch and location of the helix inside the tank is pre-determined by the geometry of the sleeve. Calculations show that a 5 / 16-in diameter condenser can be pushed through a ¾-inch, sleeved hole in a tank, and that a 50-foot long condenser section, 5 / 16-in diameter, will form a helical condenser inside the tank providing more than 4 sq. ft. of condenser surface insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com