Porous membrane materials as structured packing for distillation

a membrane material and structure technology, applied in the direction of membranes, separation processes, organic chemistry, etc., can solve the problems of enormous capital and operating costs associated with distillation, extremely low temperatures and high pressures, and even larger energy consumption used in the distillation process worldwid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

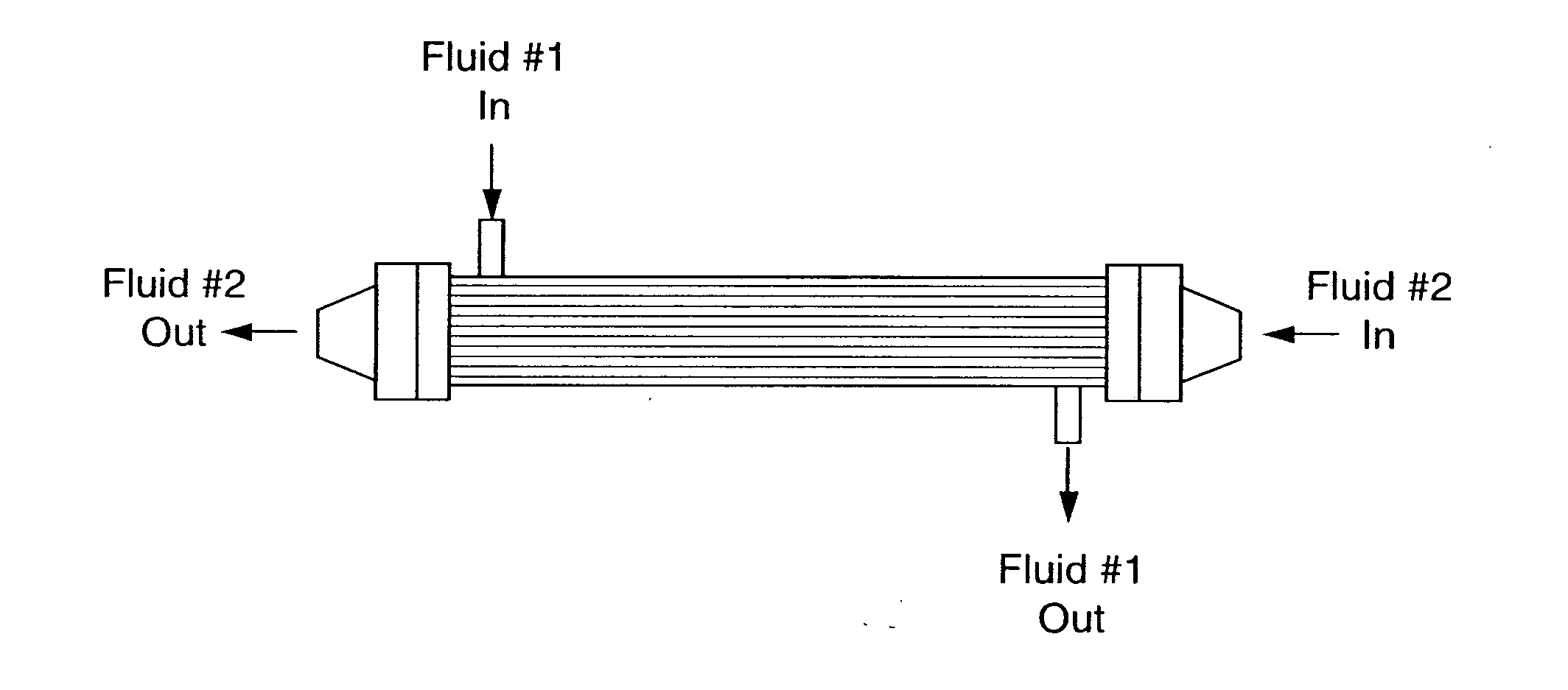

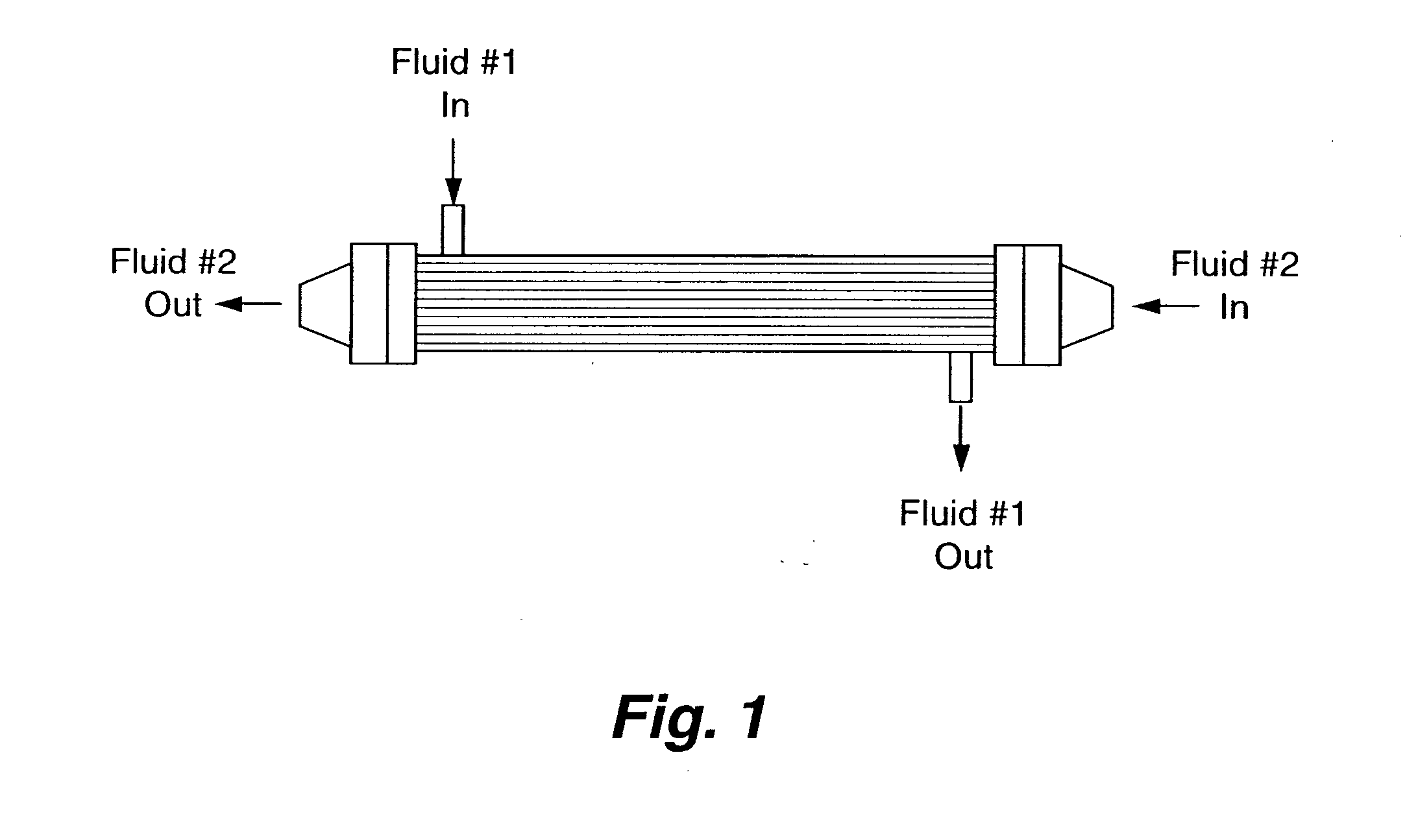

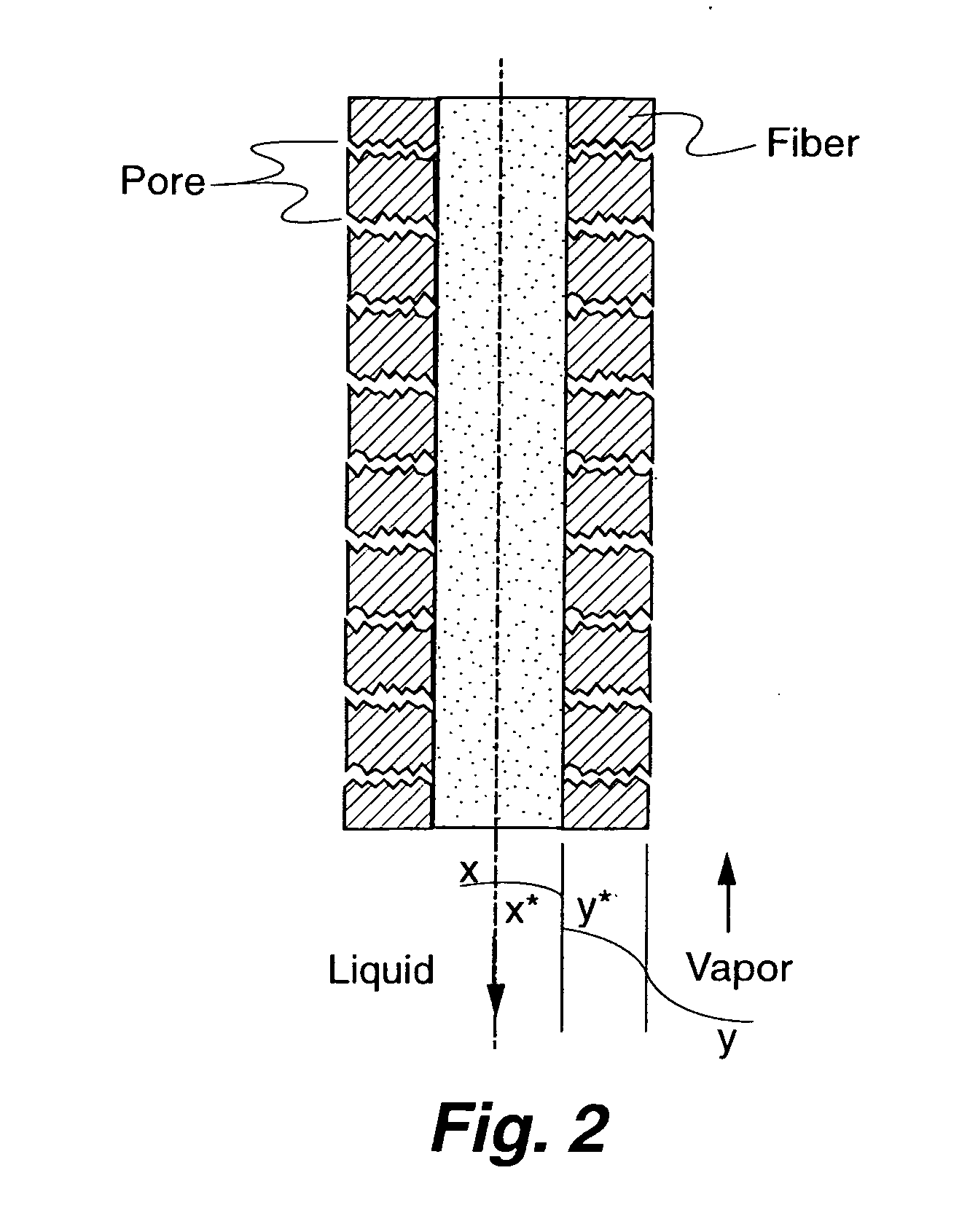

[0033] The present invention includes the use of non-selective mesoporous and / or microporous fibers as structured packing for separation of light hydrocarbons like olefinic mixtures and olefin and paraffin mixtures. Mesoporous is defined as a material with pore size of less than 0.01 micrometer. Microporous is defined as a material with pore size in the micrometer range (a few hundred micrometers to 0.01 micrometer). Testing results prove that the hollow fiber made of non-selective mesoporous and / or microporous fibers can be used as structured packing, thus, allowing for an alternative technology for conventional distillation.

[0034] Non-selective mesoporous and / or microporous materials that may be used in this application include, but are not limited to: plastics (e.g. polypropylene, polysulfone, polyethylene, polyvinylididene, mixed ester, and polyestersulfone), ceramics, and metals. Preferred embodiments of these materials exhibit pore sizes that ranges from about 0.02 to a few h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com