Fixed scroll of scroll compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

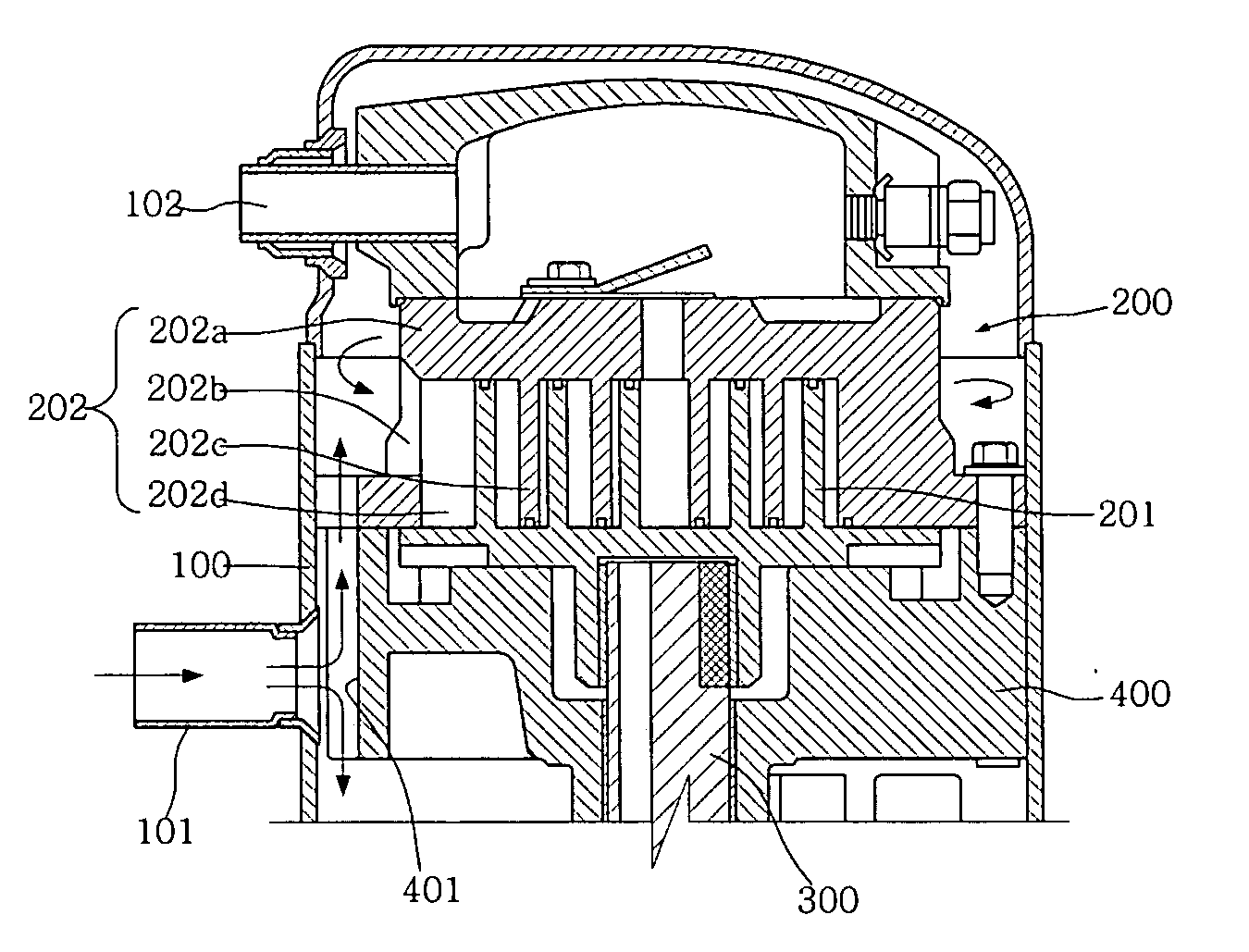

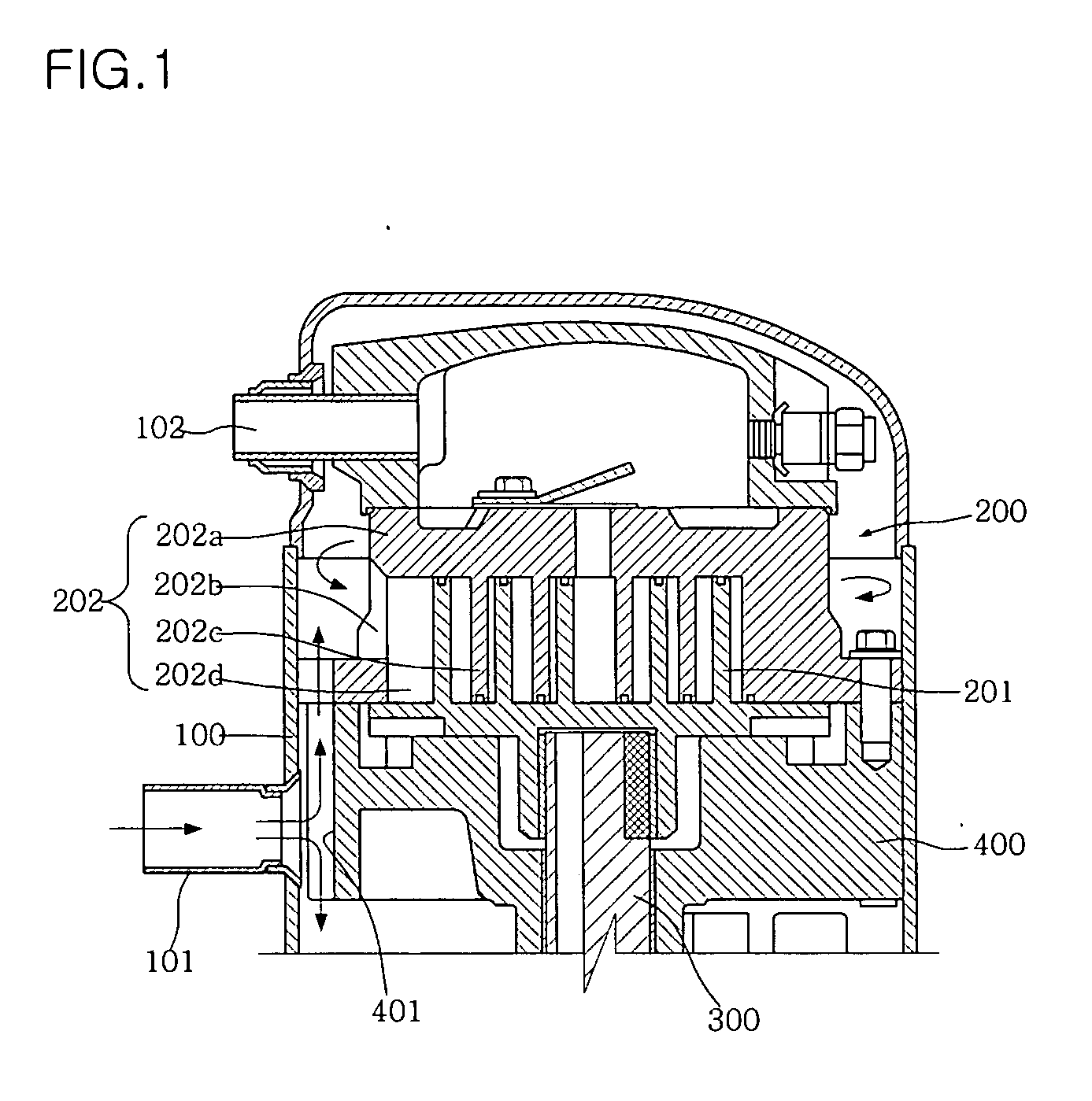

[0026] Now, a preferred embodiment of the present invention will be explained with reference to the accompanying drawings.

[0027]FIG. 3 is a bottom perspective view of a fixed scroll in accordance with the present invention. FIG. 4 is a perspective view illustrating the fixed scroll of FIG. 3, which is coupled to a main frame.

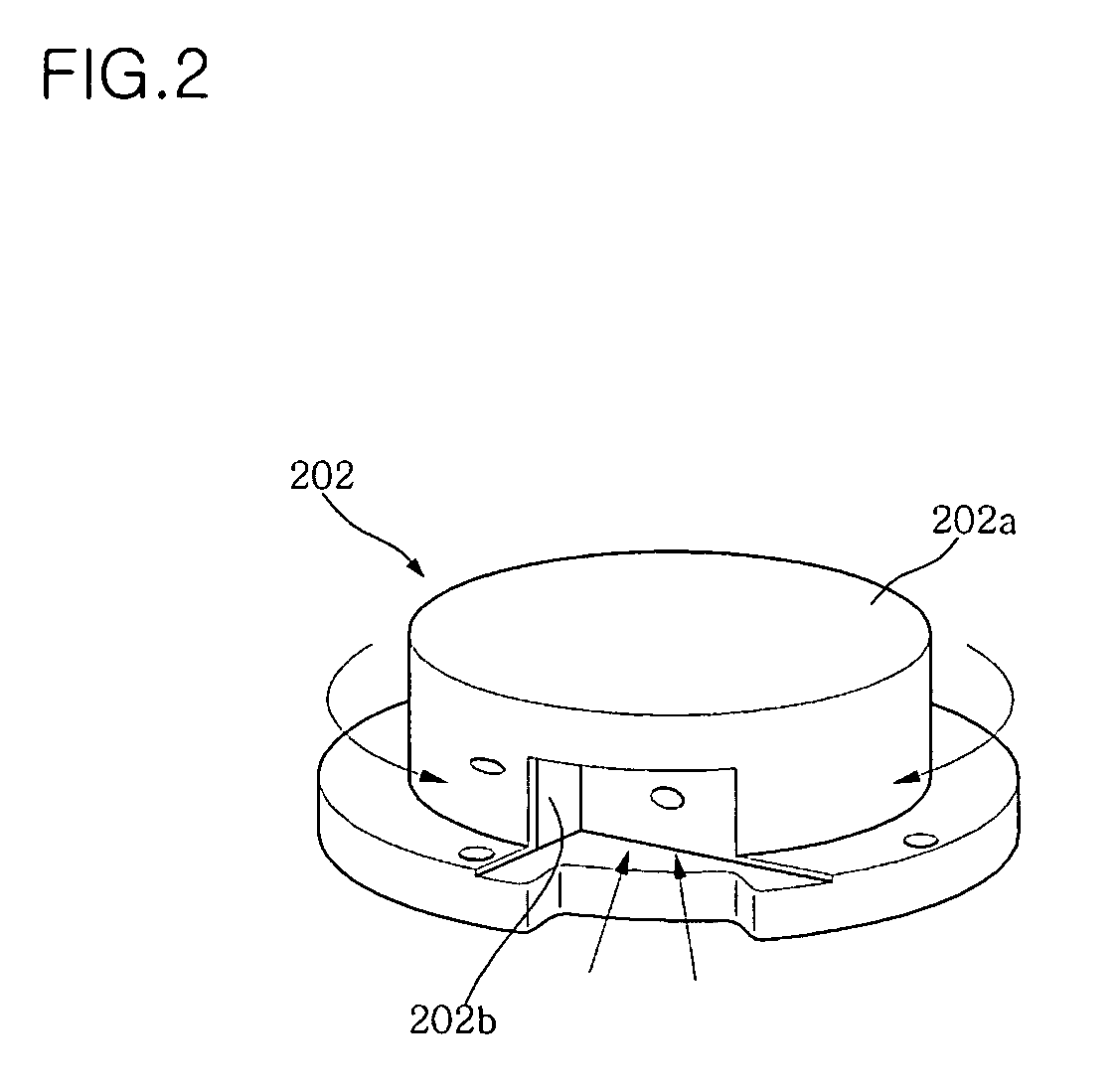

[0028] As shown in FIGS. 3 and 4, the fixed scroll 1 of a scroll compressor includes a scroll body 10 arranged on an upper surface of a main frame 2 and defining a compression chamber 11 therein, and an interceptive suction portion 20 formed at the scroll body 10 to guide gaseous refrigerant into the compression chamber 11.

[0029] The scroll body 10 has an involuted wrap 12 to define the compression chamber 11 therein, and a mounting flange 13 formed around a lower end of the scroll body 10 to be mounted on the upper surface of the main frame 2.

[0030] The interceptive suction portion 20 serves to guide only suctioned gaseous refrigerant, that is directed upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com