Height comparator

a comparator and height technology, applied in the direction of automatic grinding control, sport apparatus, skating parts, etc., can solve the problems of affecting the productivity of operators, affecting the efficiency of operators, and affecting the accuracy of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

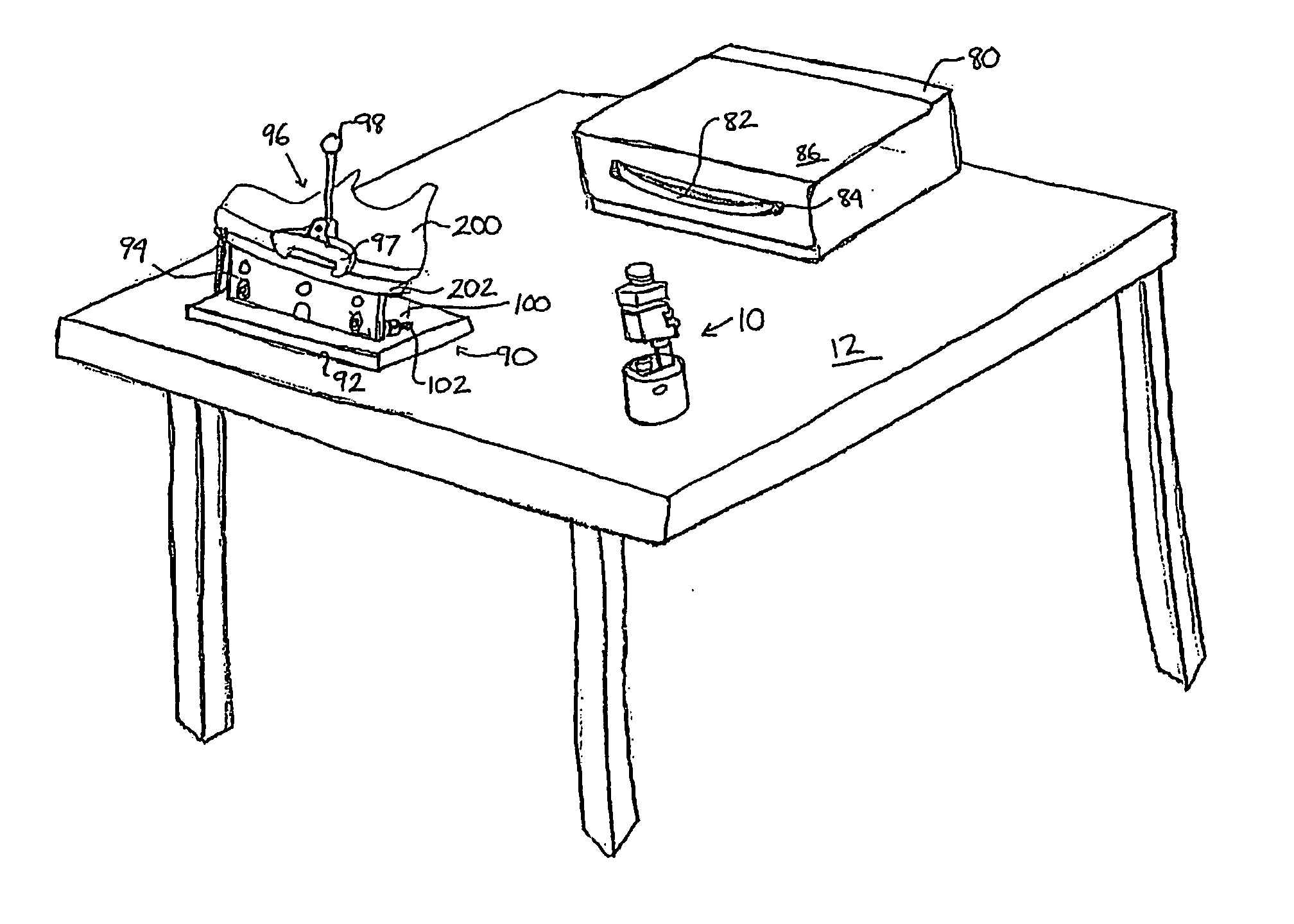

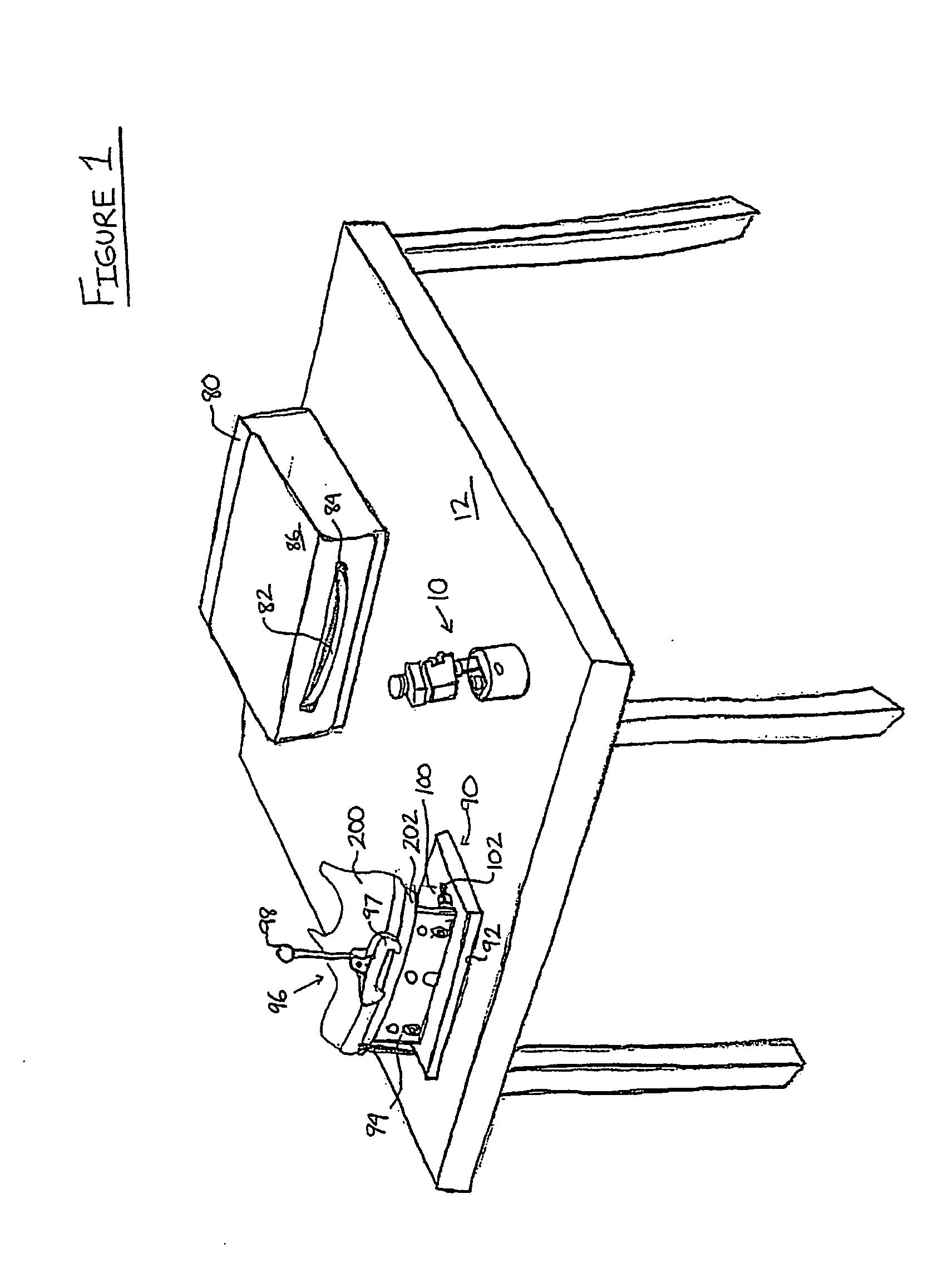

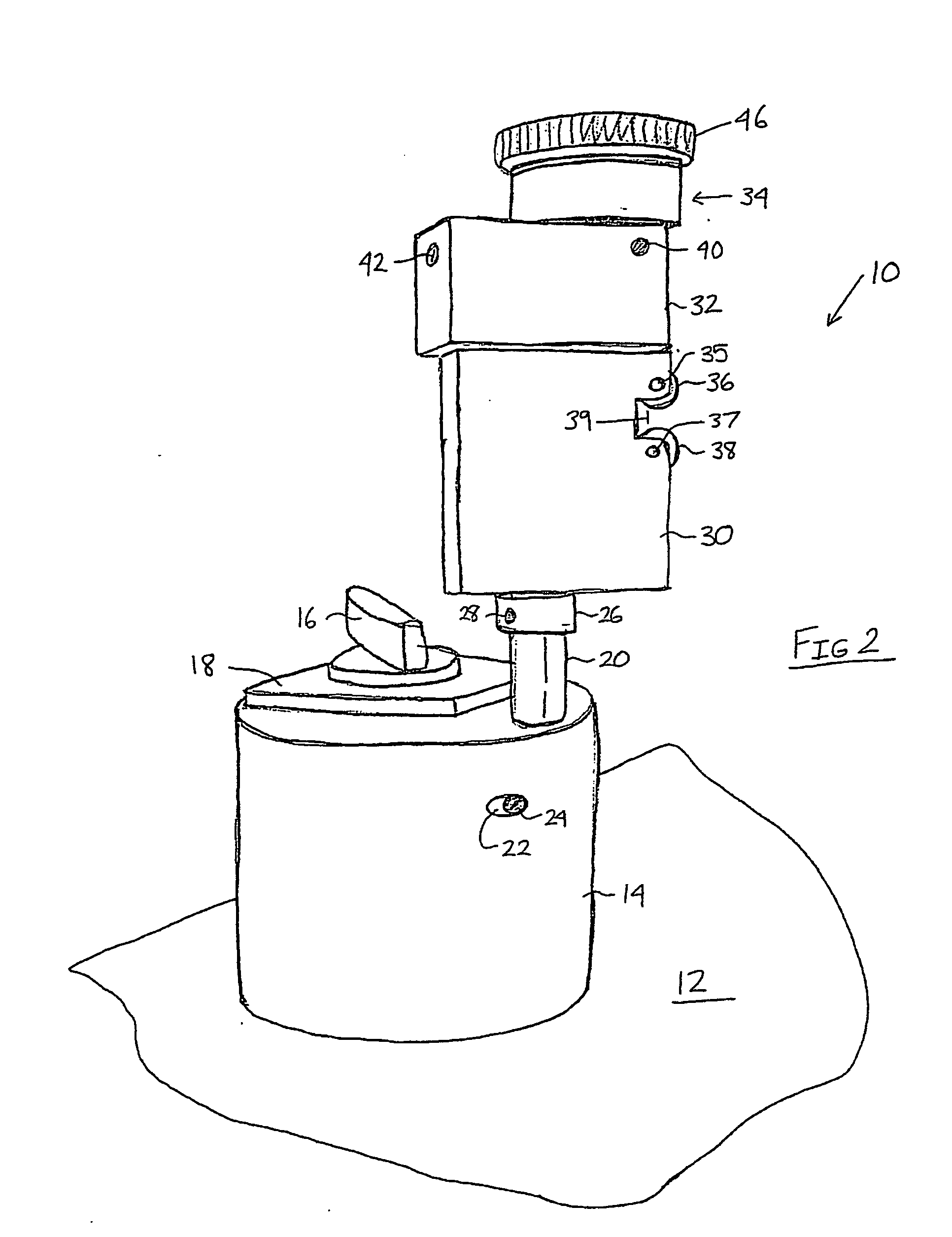

[0022] Referring therefore to FIG. 1, a typical skate sharpening environment is shown. A table has a working surface 12 that supports a skate sharpening machine 80. The working surface 12 is preferably made of a material that is attracted to a magnet. The machine 80 is mounted on the surface 12, and a portion of a grinding wheel 82 protrudes through a slot 84 formed in a shield 86. The surface 12 also supports a clamping-type skate holder 90. The holder 90 has a base 92 that rests on the surface 12. The base 92 supports a levelling plate 94 with a pair of levelling mechanisms 100 (one of them is not shown) having adjustment handles 102. A skate 200, having a blade 202, is clamped between the plate 94 and a jaw 97. The jaw 97 is part of a clamping mechanism 96, and is operated by pivoting a handle 98, which is also part of the clamping mechanism 96. A device for measuring the height of an object to be used in setting the height of another object is also supported on the surface 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com