Combination lift and anchor connector for fabricated wall and floor panels

a technology of fabricated wall and floor panels and anchor connectors, which is applied in the field of low density prefabricated concrete building panels, can solve the problems of increasing the odds of cracking or otherwise changing the floor panel, the method of interconnecting the wall panel with the floor panel is slightly more labor-intensive, etc., and achieves the effect of simple and cost-effective installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

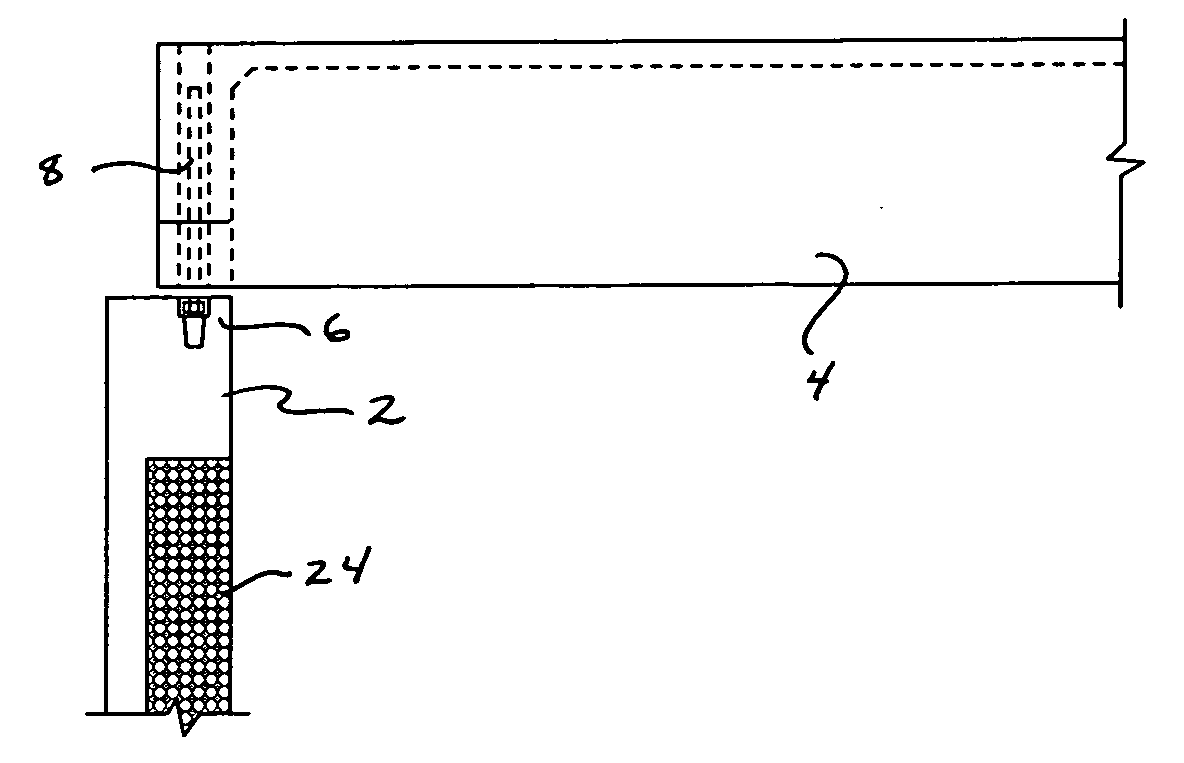

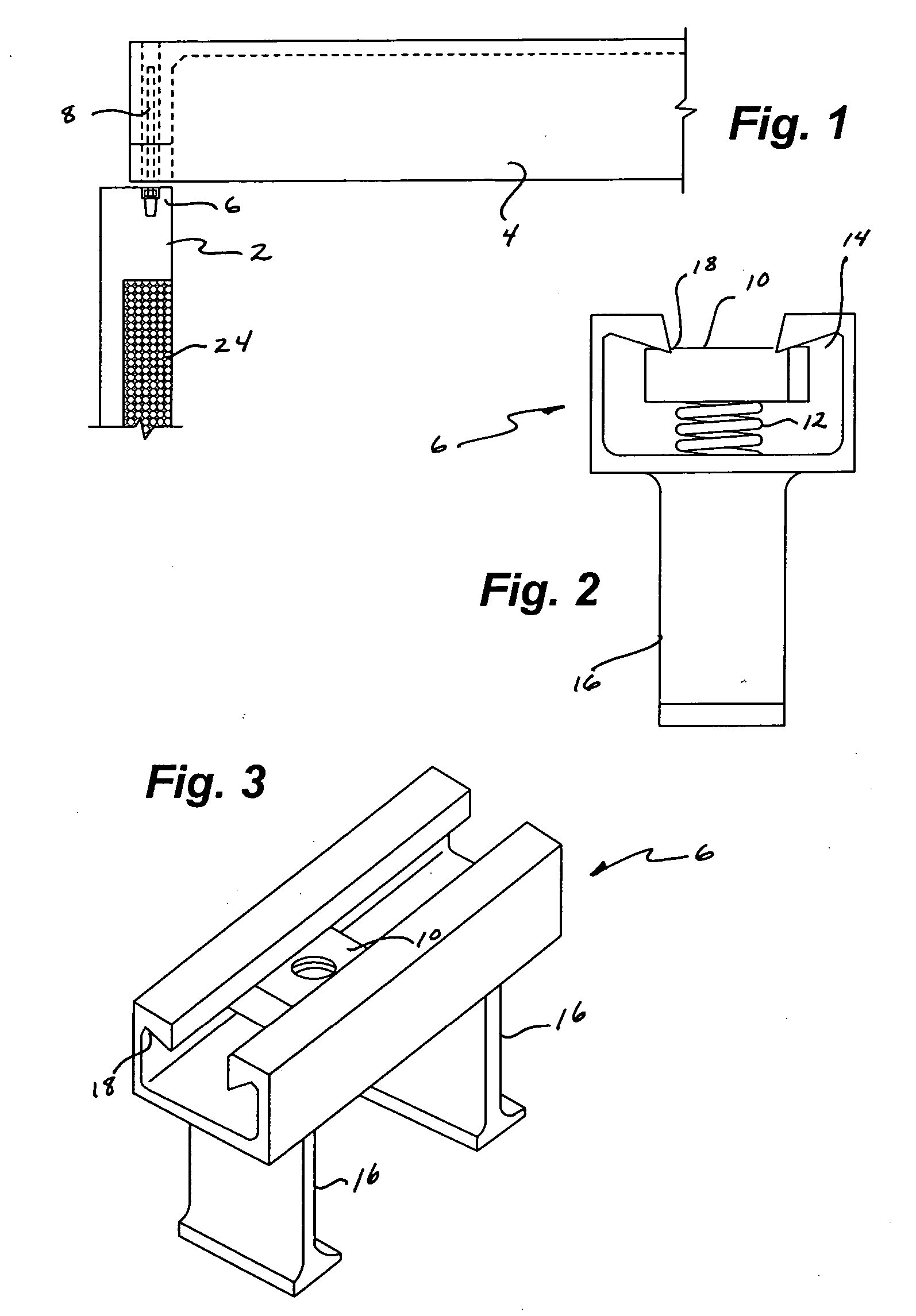

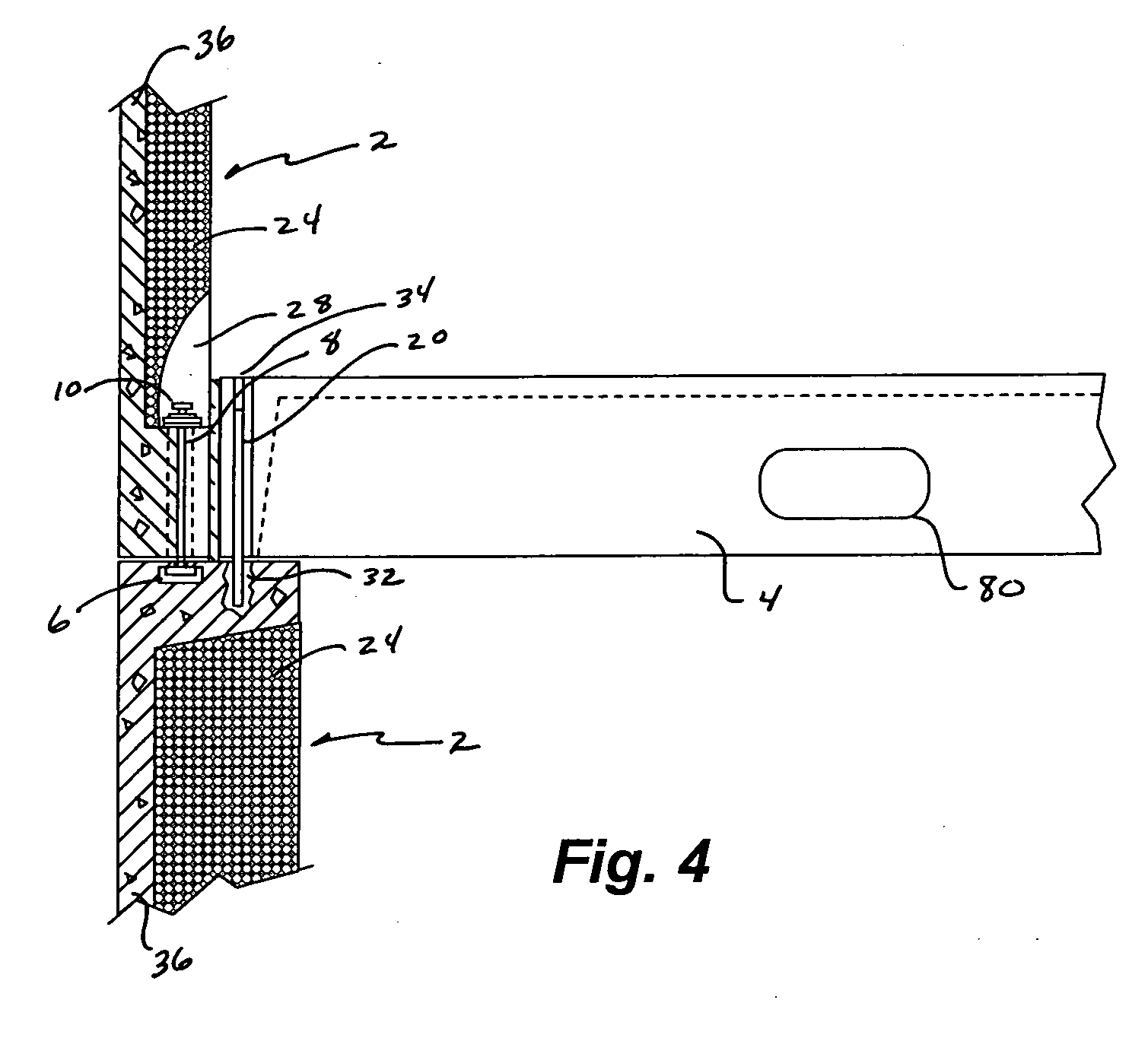

[0037] Referring now to FIGS. 1-11, a combination lift and anchor connector for fabricated wall and floor panels is provided herein. More specifically, an apparatus and method for interconnecting a floor panel 4 to a wall panel 2 or two wall panels 2 constructed of precast concrete and other materials is provided. One embodiment of the present invention includes an adjustable interconnection device 6 that includes a slidable captive nut 10 or other mechanism. The adjustable interconnection device 6 is integrated into the concrete wall panel 2 during construction such that it will be located adjacent to an aperture 26 integrated into the floor panel 4 after assembly. Prior to the placement of the floor panel 4 over the wall panel 2, minute changes to the location of the captive nut 10 may be made such that a threaded rod 8 may be placed through the aperture 26 integrated into the floor panel 4 to interconnect with the captive nut 10. Once the threaded rod 8 is secured to the captive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com