Muffler with improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

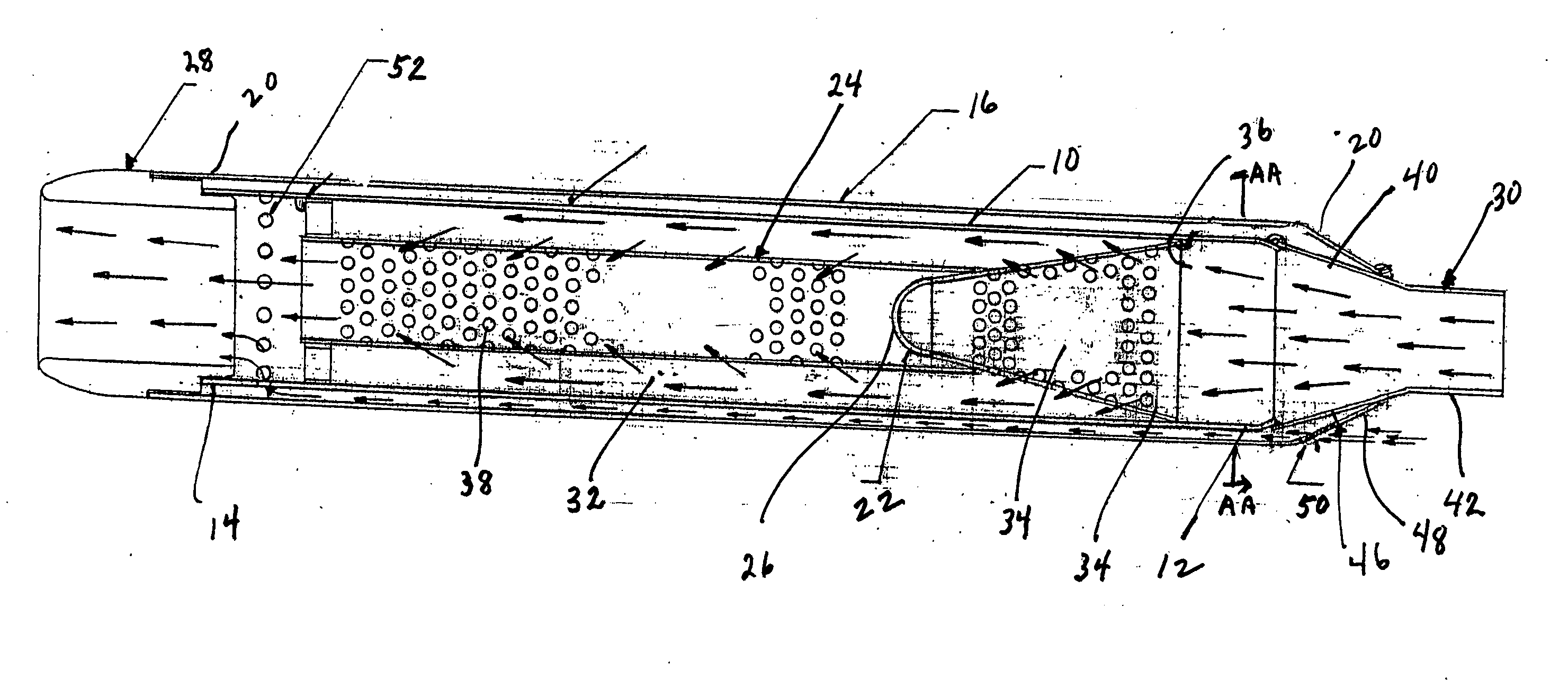

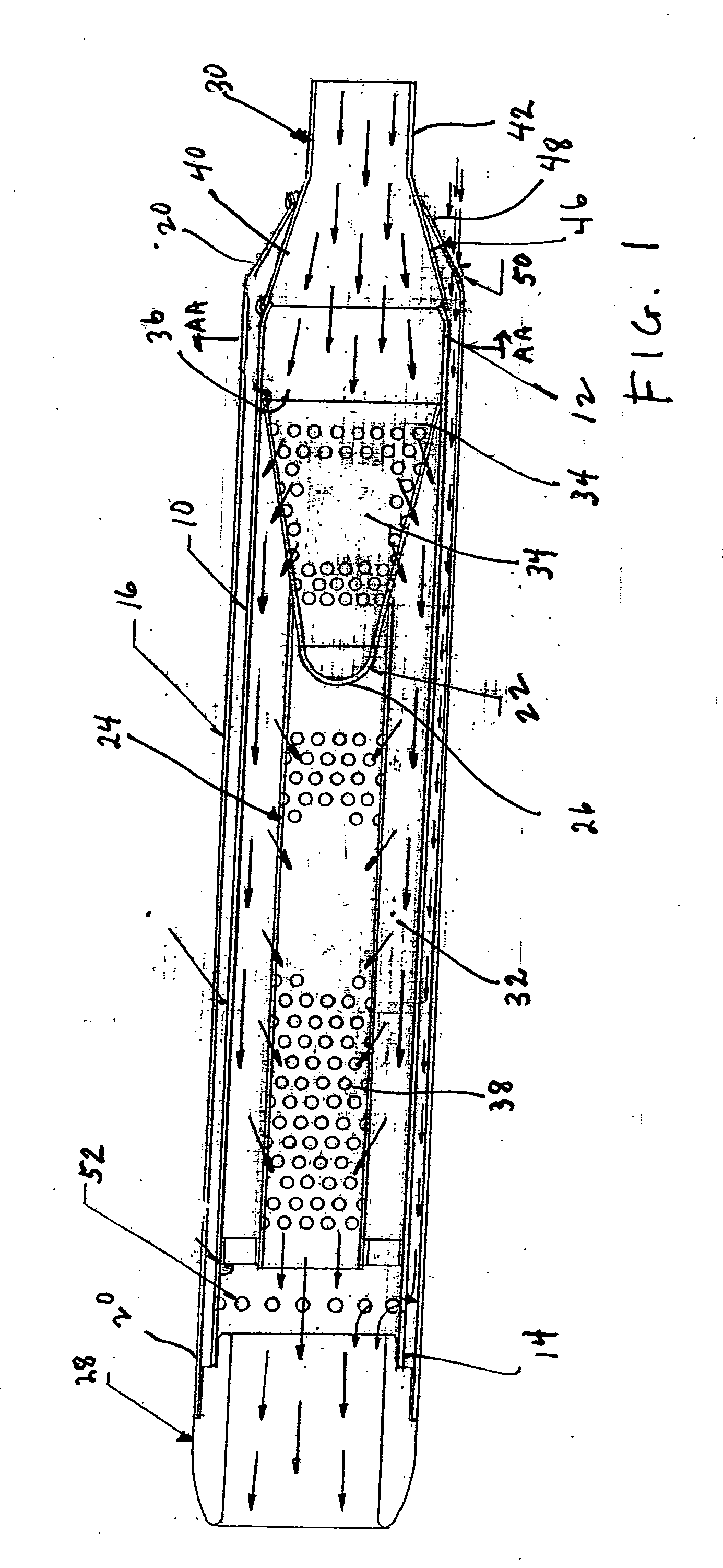

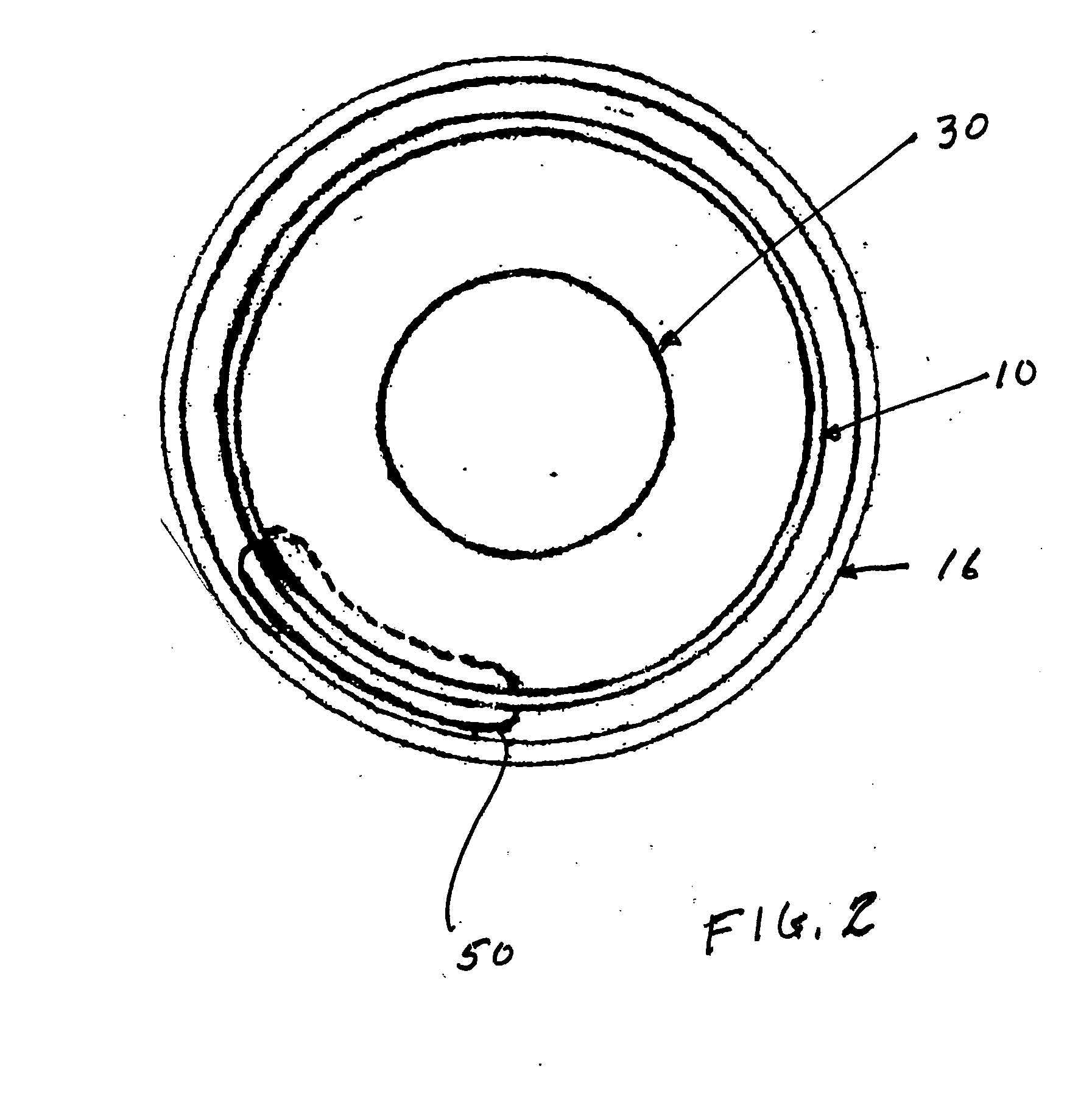

[0018]FIG. 1 illustrates an engine muffler / exhaust extractor embodying the present invention which is generally comprised of an inner tubular or cylindrical casing generally designated by the numeral 10 having an inlet end 12 and an outlet end 14, and an outer tubular or cylindrical casing generally designated by the numeral 16 having an inlet end 18 and an outlet end 20.

[0019] Seated within the inner casing 10 adjacent its inlet end 12 is a frustoconical baffle generally designated by the numeral 22. Also seated within the casing 10 is a cylindrical baffle generally designated by the numeral 24 which extends over the small diameter end portion 26 of the frustoconical baffle 22 and is supported adjacent the discharge end by the support cap generally designated by the numeral 28. At the inlet end of the casing 10 is an inlet fitting generally designated by the numeral 30. The baffles 22 and 24 are dimensioned so that there is an annular space between them and the inner casing 10 pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap