Semiconductor thin film decomposing method, decomposed semiconductor thin film, decomposed semiconductor thin film evaluation method, thin film transistor made of decomposed semiconductor thin film, and image display device having circuit constituted of thin film transistors

a semiconductor and thin film technology, applied in the direction of non-linear optics, manufacturing tools, instruments, etc., can solve the problems of irregular grain size and protrusion height, and long crystallization process time. , to achieve the effect of reducing protrusions and long crystallization process tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

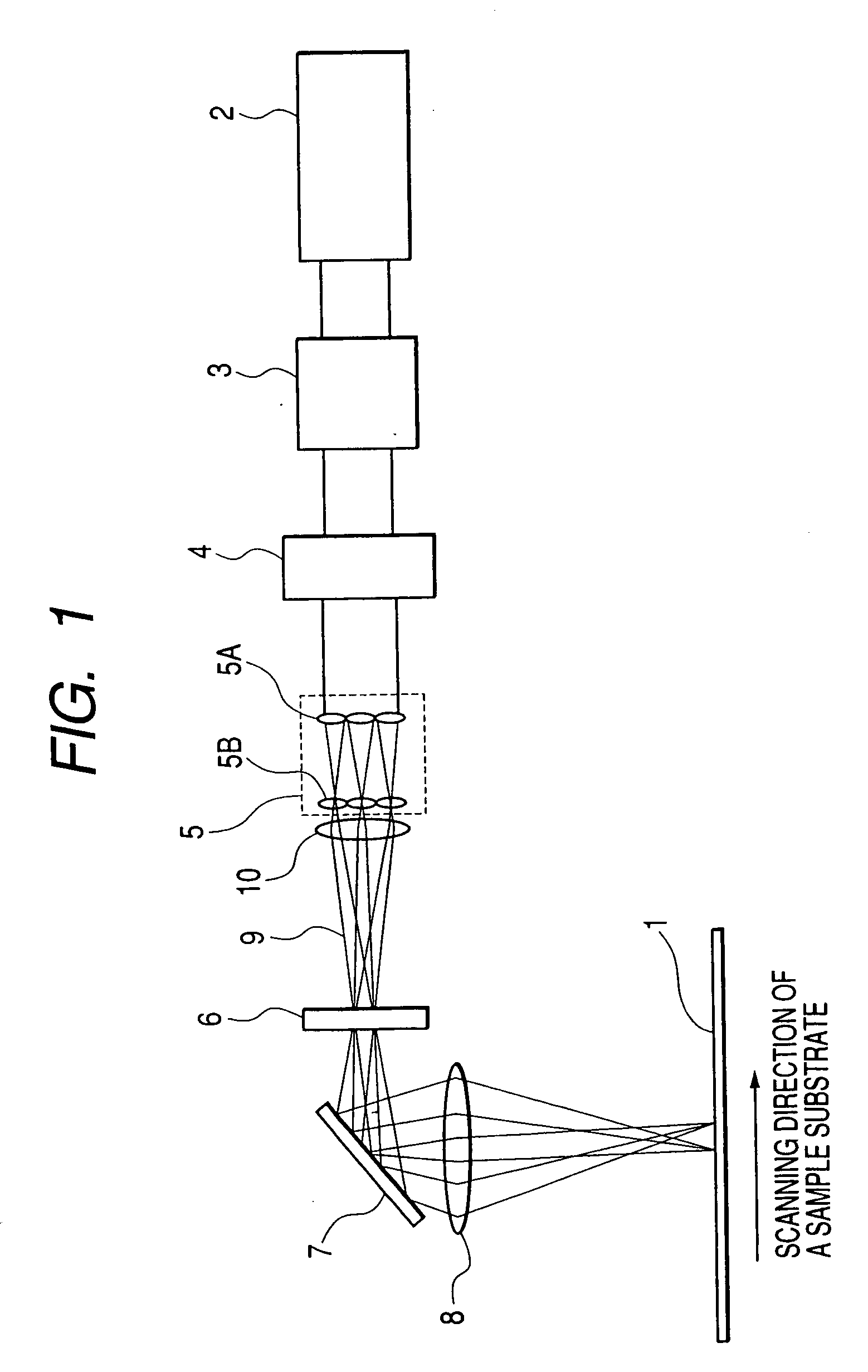

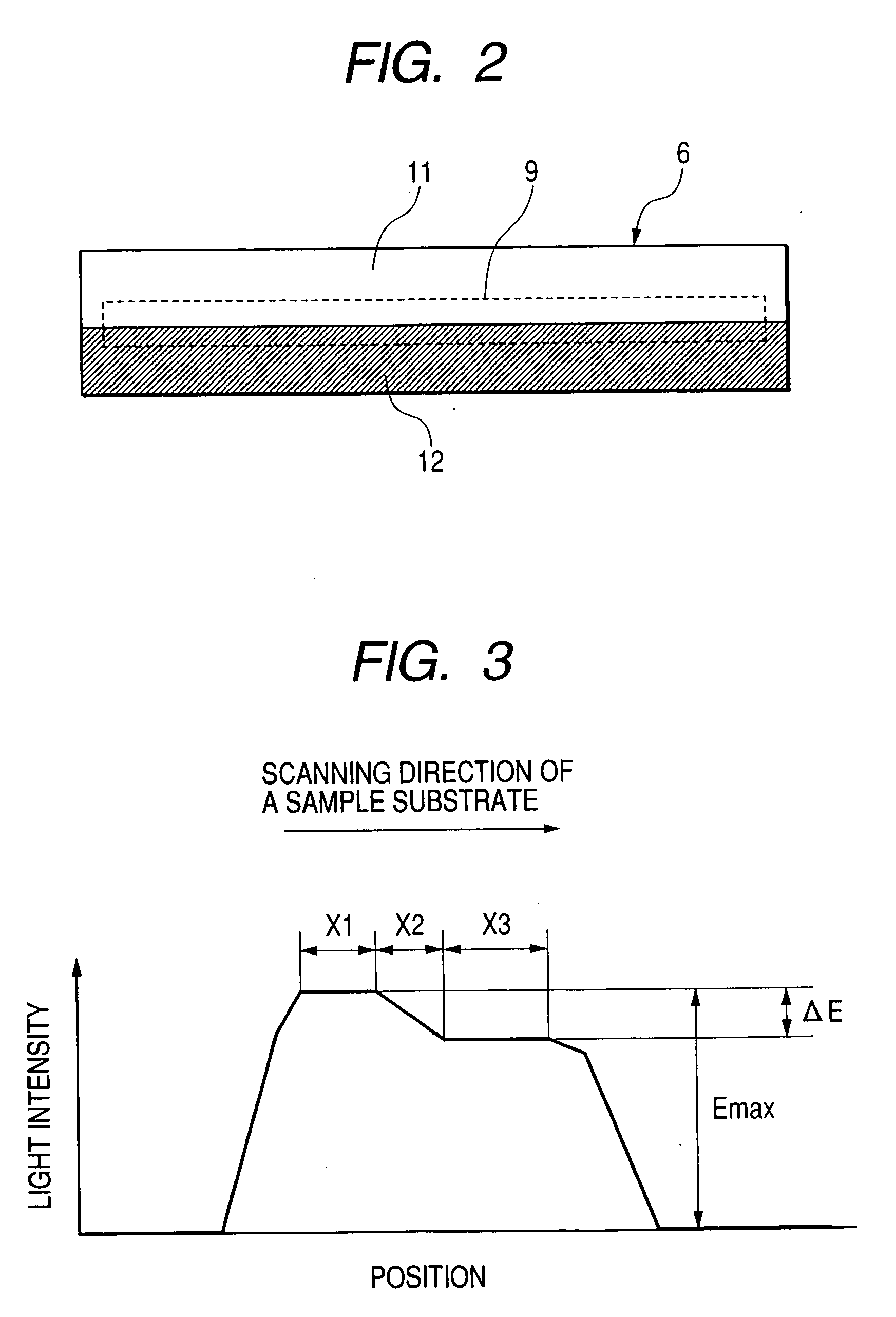

[0074]FIG. 1 is a schematic diagram showing an example of an optical system of a laser annealing apparatus realizing a semiconductor decomposition method of the present invention. In this embodiment, a transmittance distribution control filter of the present invention is applied to an excimer laser annealing apparatus used generally. Referring to FIG. 1, a laser source 2 is a STEEL1000 type XeCl excimer laser source manufactured by Lambda Physik. The wavelength of an output laser beam is 308 nm, a pulse time duration is about 27 ns, a repetition frequency is 300 Hz and a pulse energy is 1 J / pulse. This laser annealing apparatus was manufactured by Japan Steel Works, Ltd. A laser beam shaped to a line beam having a long axis length of 365 mm and a short axis length of 400 μm is irradiated to a substrate, by using a long axis homogenizer optical system 4 and a short axis homogenizer optical system 5 manufactured by MicroLas and a cylindrical lens 10, a cylindrical lens 8 and a mirror ...

second embodiment

[0081] Next, with reference to FIGS. 5 and 6, the second embodiment will be described. FIG. 5 is a schematic diagram showing another example of the optical system of the laser annealing apparatus realizing the semiconductor manufacture method of the present invention. FIG. 6 is a schematic diagram showing an example of the structure of a transmittance distribution filter 6 shown in FIG. 5. This embodiment has fundamentally the same structure constituted of the laser source 2 and laser annealing apparatus of the first embodiment described with reference to FIG. 1. Different points of the second embodiment from the first embodiment reside in that the transmittance distribution filter 16 is disposed just in front of a short axis homogenizer 5 and that the transmittance distribution of the transmittance distribution filter 16 has a shape of stripes so as to control the intensity distribution in respective lenses of the cylindrical lens array in the short axis homogenizer 5 as shown in F...

third embodiment

[0083] In this embodiment, the transmittance distribution filter is applied to the crystallization method using a phase shift stripe mask. FIG. 7 is a schematic diagram showing another example of the optical system of the leaser annealing apparatus using the phase shift stripe method realizing the semiconductor manufacture method of the present invention. This embodiment uses a general excimer laser annealing apparatus using a line beam of the above-described first and second embodiments. The position of the transmittance distribution filter 6 may be the same as that shown in FIG. 1 or 5. In FIG. 7, the position of the transmittance distribution filter is the same as that shown in FIG. 1. In this embodiment, a phase stripe mask 41 is disposed near a substrate 1. The mask may be disposed on the first order focussing plane.

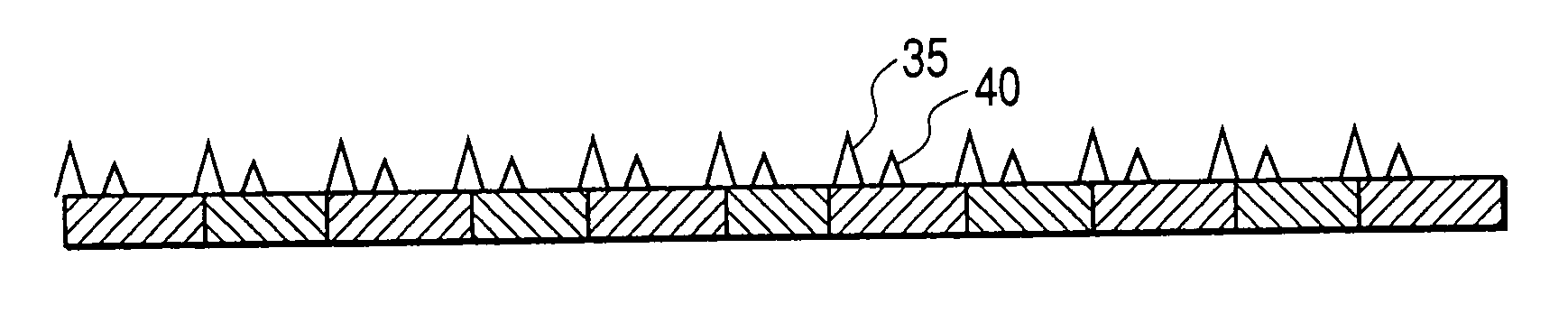

[0084]FIG. 8 is a diagram illustrating a method of crystallizing a silicon semiconductor thin film by using a phase shift stripe mask. As shown in FIG. 8, the phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain boundary size | aaaaa | aaaaa |

| grain boundary size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com