Injection molding apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

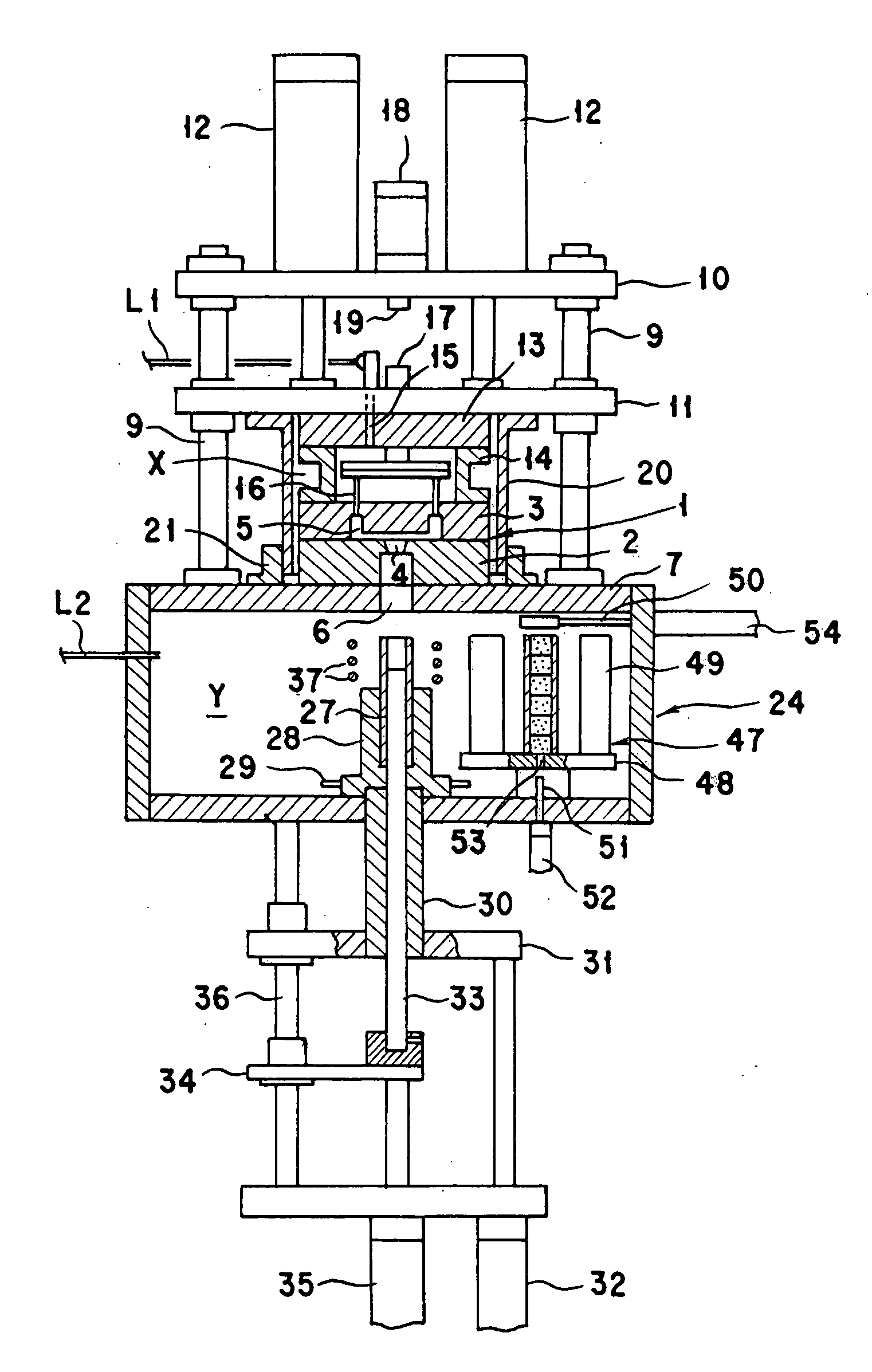

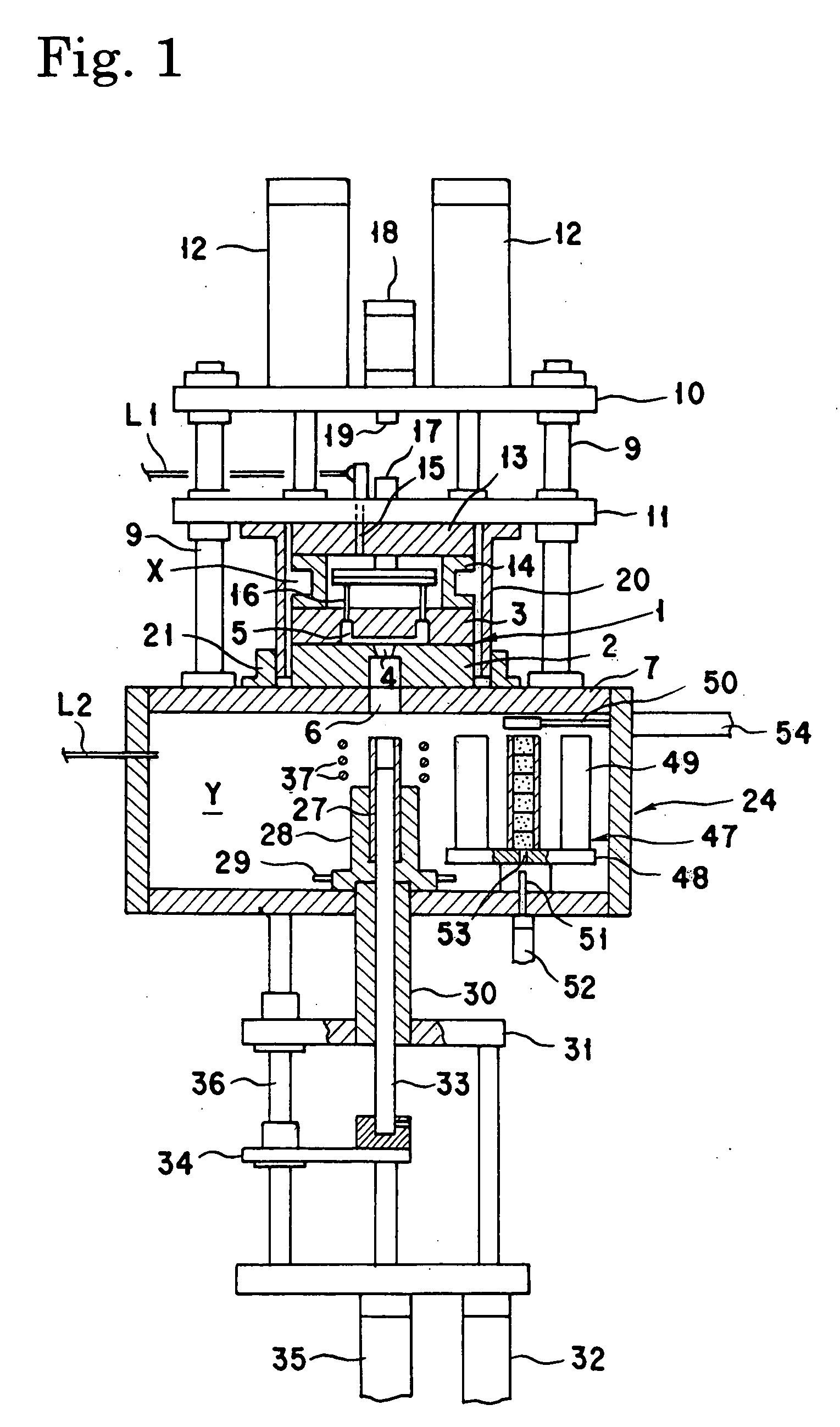

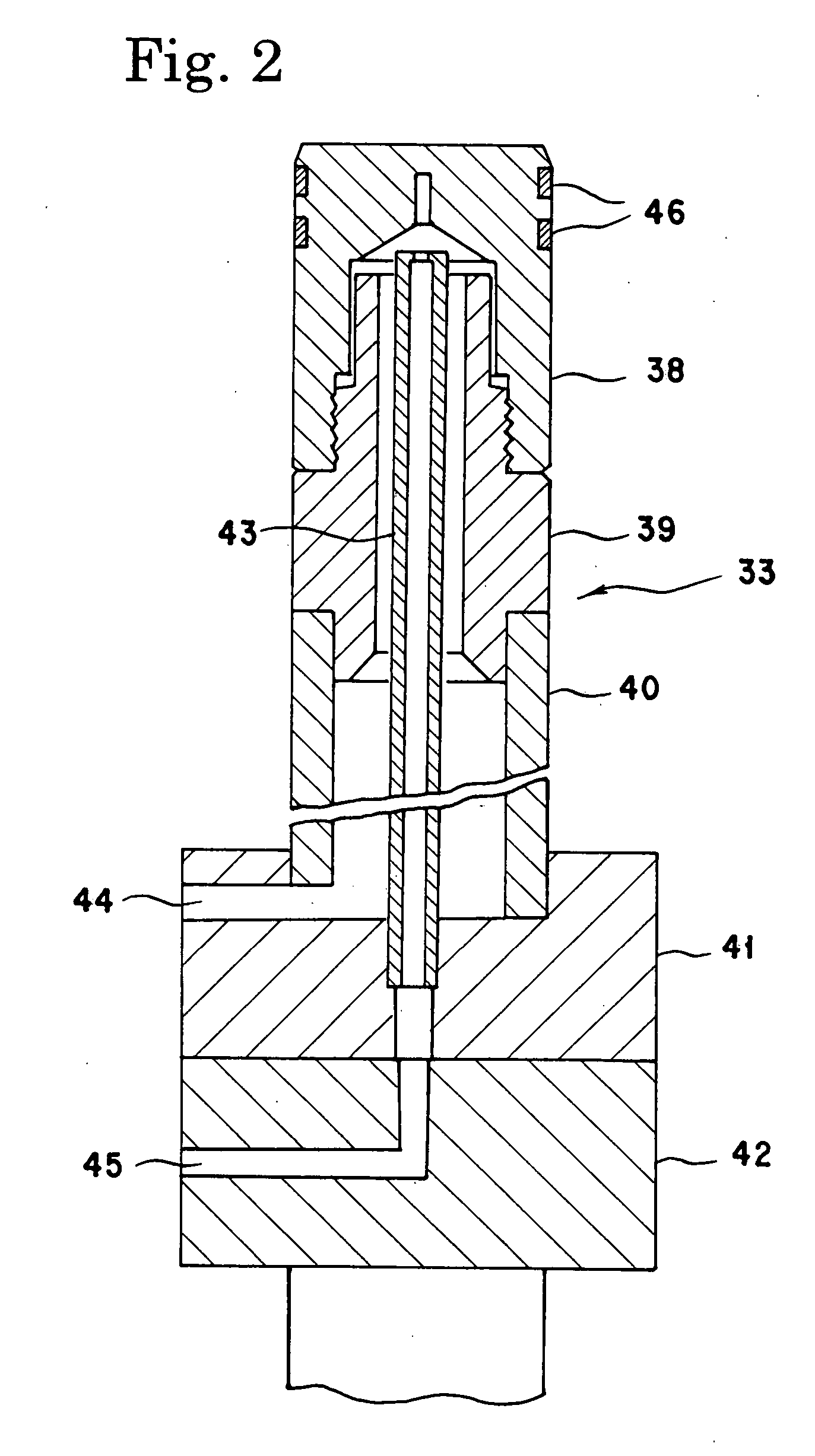

[0031] The characteristic feature of the injection molding apparatus of the present invention resides in that, as described above, in the injection molding apparatus comprising a mold, a sleeve disposed so as to be movable forward and backward toward a pouring gate of the mold, a plunger slidably disposed in the sleeve, and a heating means for heating and melting a raw material lump supplied into a raw material accommodating part formed by an inside wall of the sleeve and the plunger mentioned above, the plunger and / or the sleeve mentioned above is equipped with a cooling means and thus a melt of a metal which has been heated and melted hardly flows into a gap between the plunger and the sleeve. That is, although the molten metal heated to a higher temperature becomes easy to flow into the gap between the plunger and the sleeve, the apparatus is characterized by the fact that it is possible to prevent this phenomenon and make the sliding movement of the plunger in the sleeve becomes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com