Evaporator refrigeration system vehicle equipped with said system and method of evaporating refrigerant

a refrigeration system and evaporator technology, applied in indirect heat exchangers, lighting and heating apparatuses, transportation and packaging, etc., can solve the problems of deteriorating heat exchange performance, extremely low heat exchange efficiency, and extremely reduced heat exchange efficiency, so as to improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

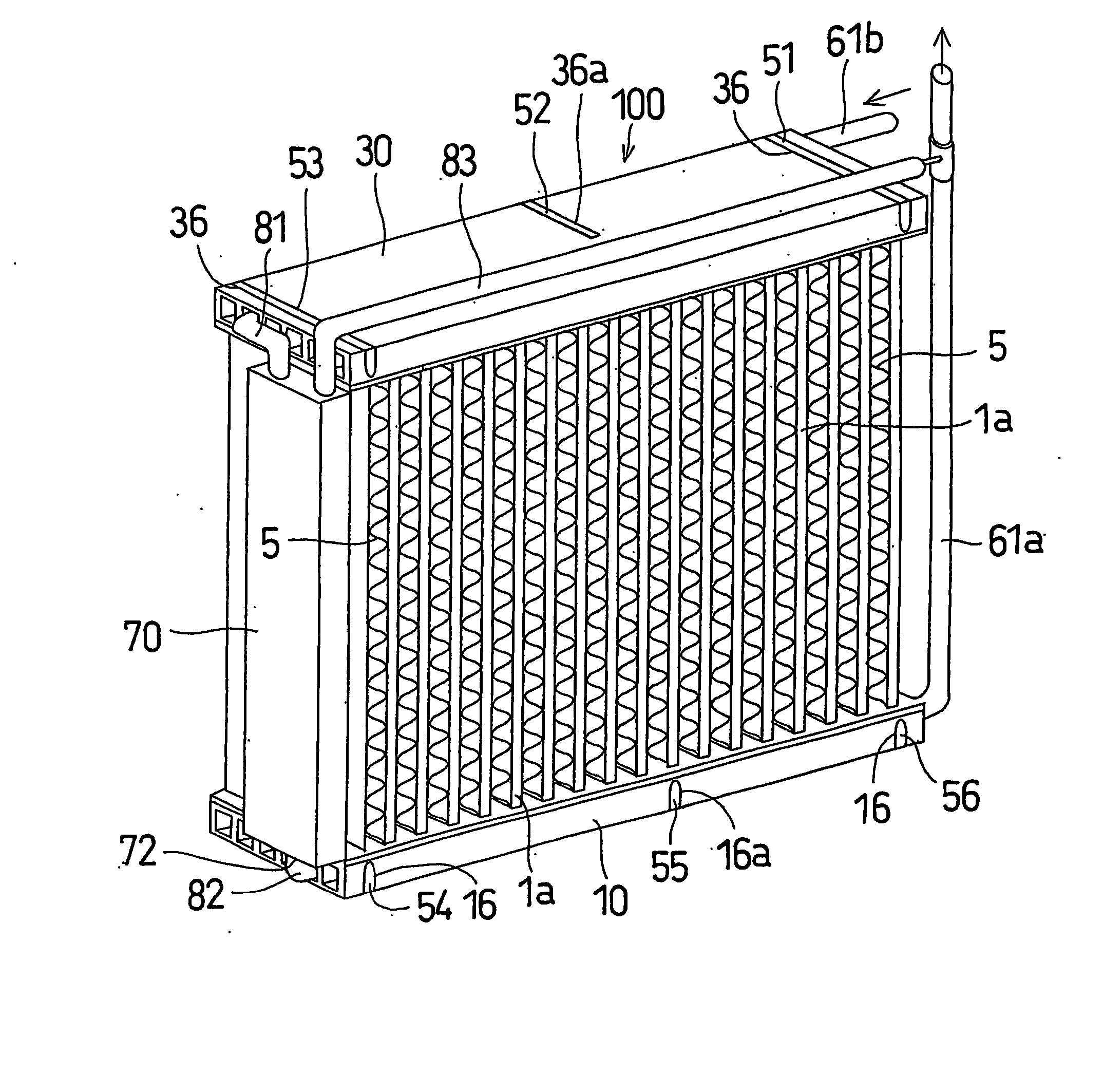

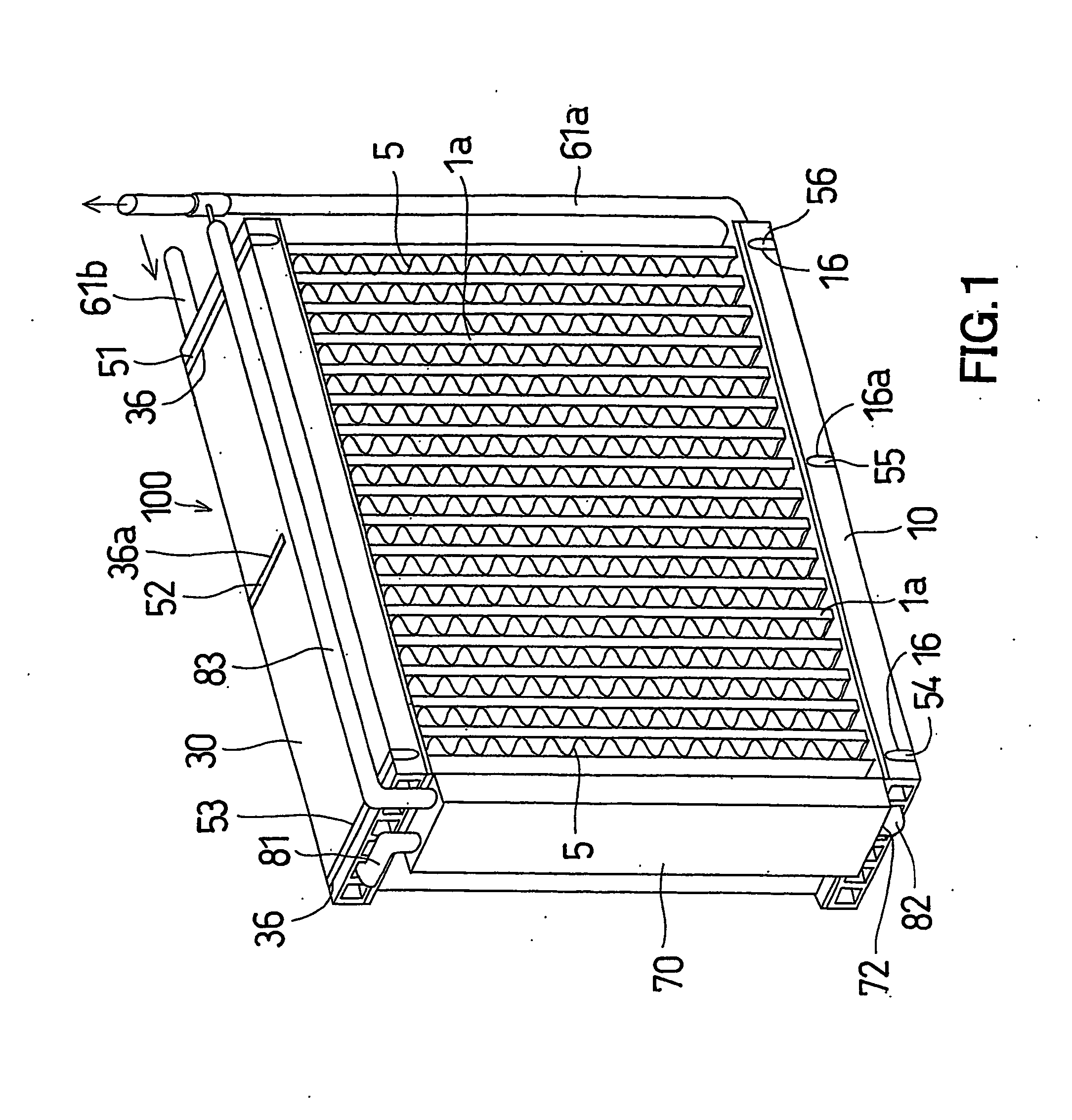

[0273] FIGS. 1 to 5 show an evaporation apparatus to be applied to a refrigeration system for use in vehicles which is an embodiment of the present invention. As shown in these figures, this evaporation apparatus is an apparatus to be applied to an vapor compressing type refrigeration cycle using CO2 as a refrigerant, and includes an evaporator 100 and a gas-liquid separator 70 provided at a part of a refrigerant passage of the evaporator 100.

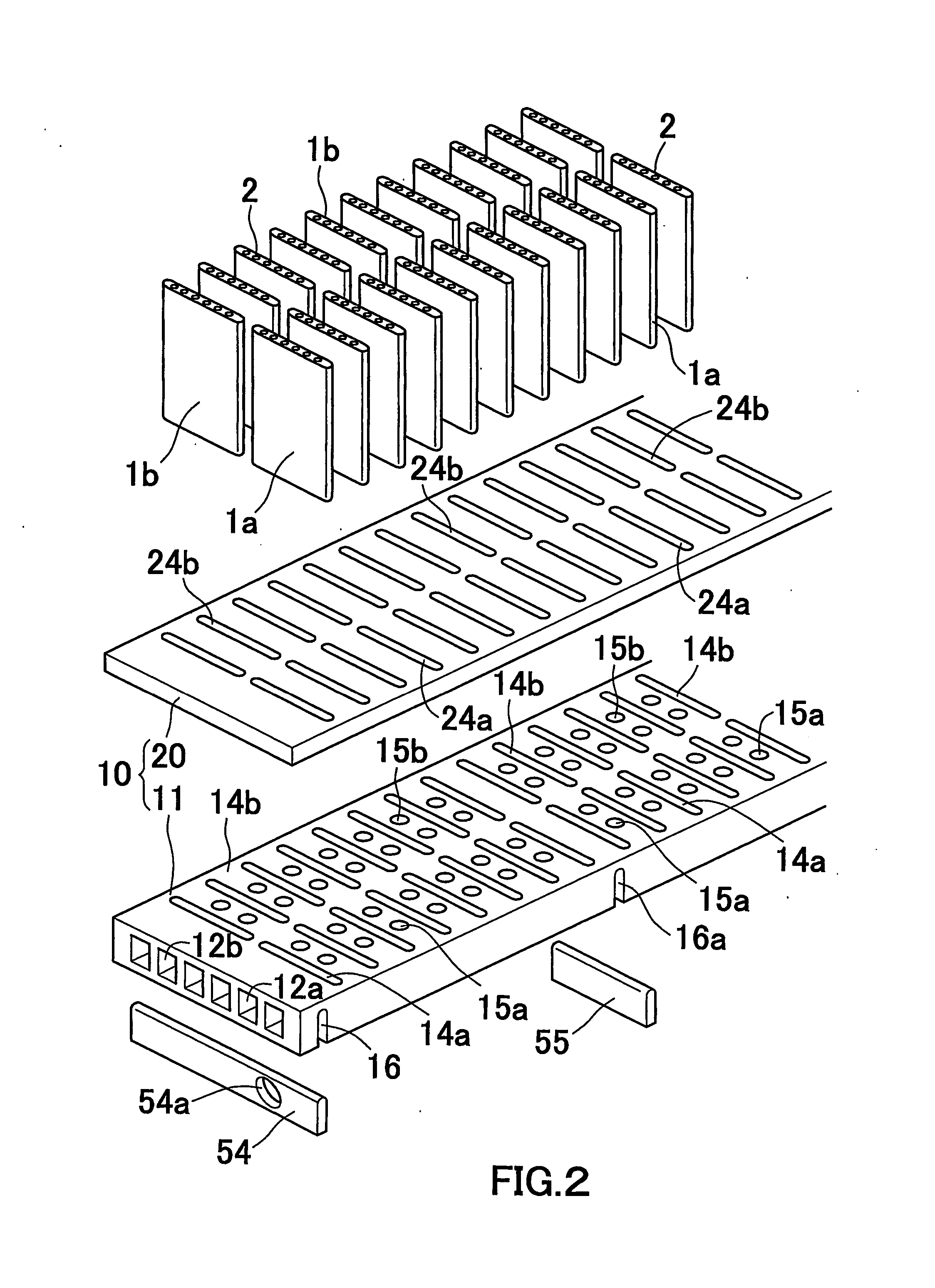

[0274] The evaporator 100 is provided with, as fundamental structural components, a pair of upper and lower flat header tanks 10 and 30, flat heat exchanging tubes 1a and 1 b disposed between the pair of header tanks 10 and 30 with both ends thereof connected to the pair of header tanks 10 and 30 in fluid communication, arranged in parallel with each other in the longitudinal direction (right and left direction) of the header tank, and arranged in two rows in the widthwise direction (fore and aft direction) of the header tank, and corrugated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com