Masonry wall system

a masonry wall and system technology, applied in the direction of structural elements, building components, construction materials, etc., can solve the problems of affecting the use of fasteners on masonry wall construction, and requiring complex mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

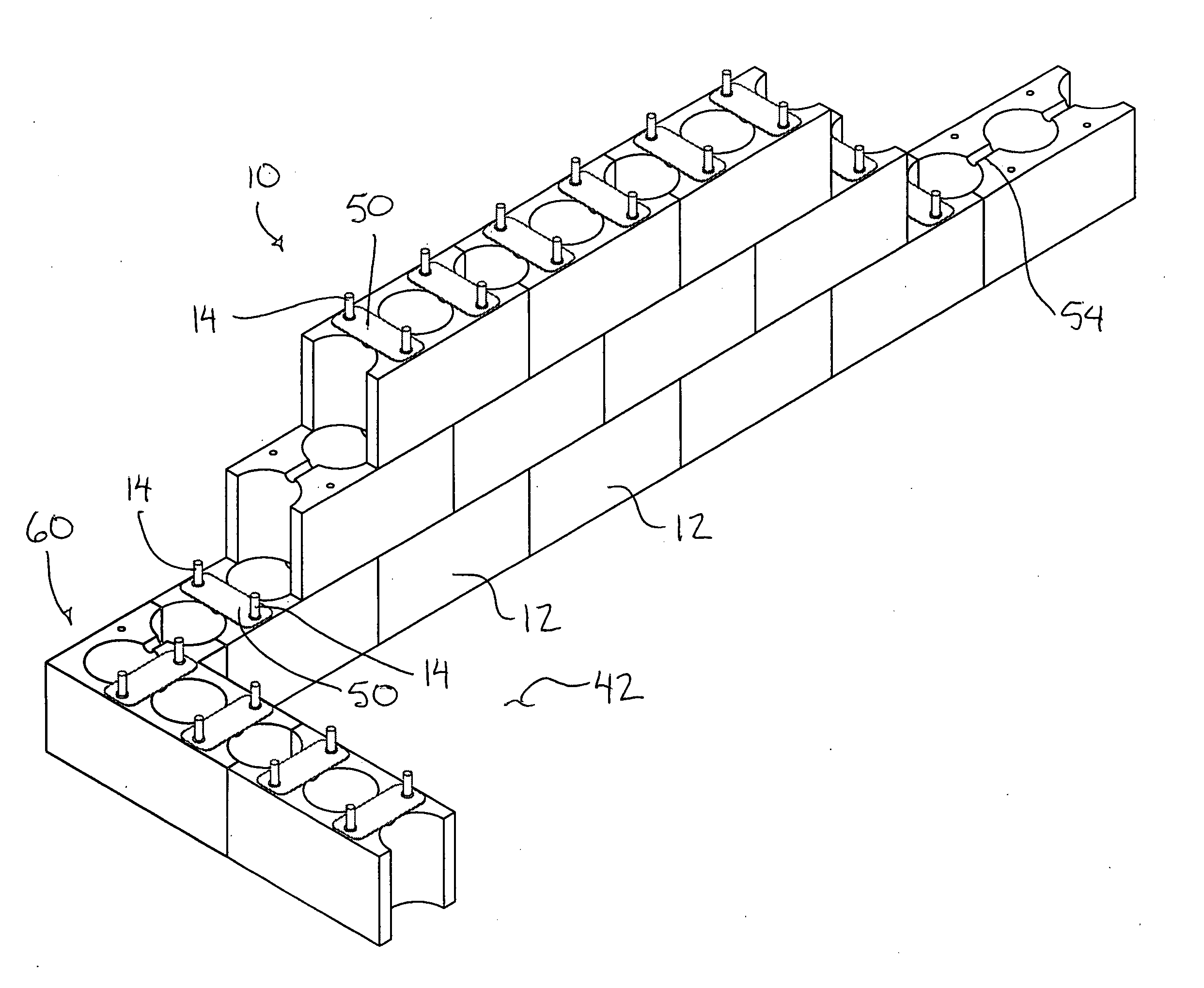

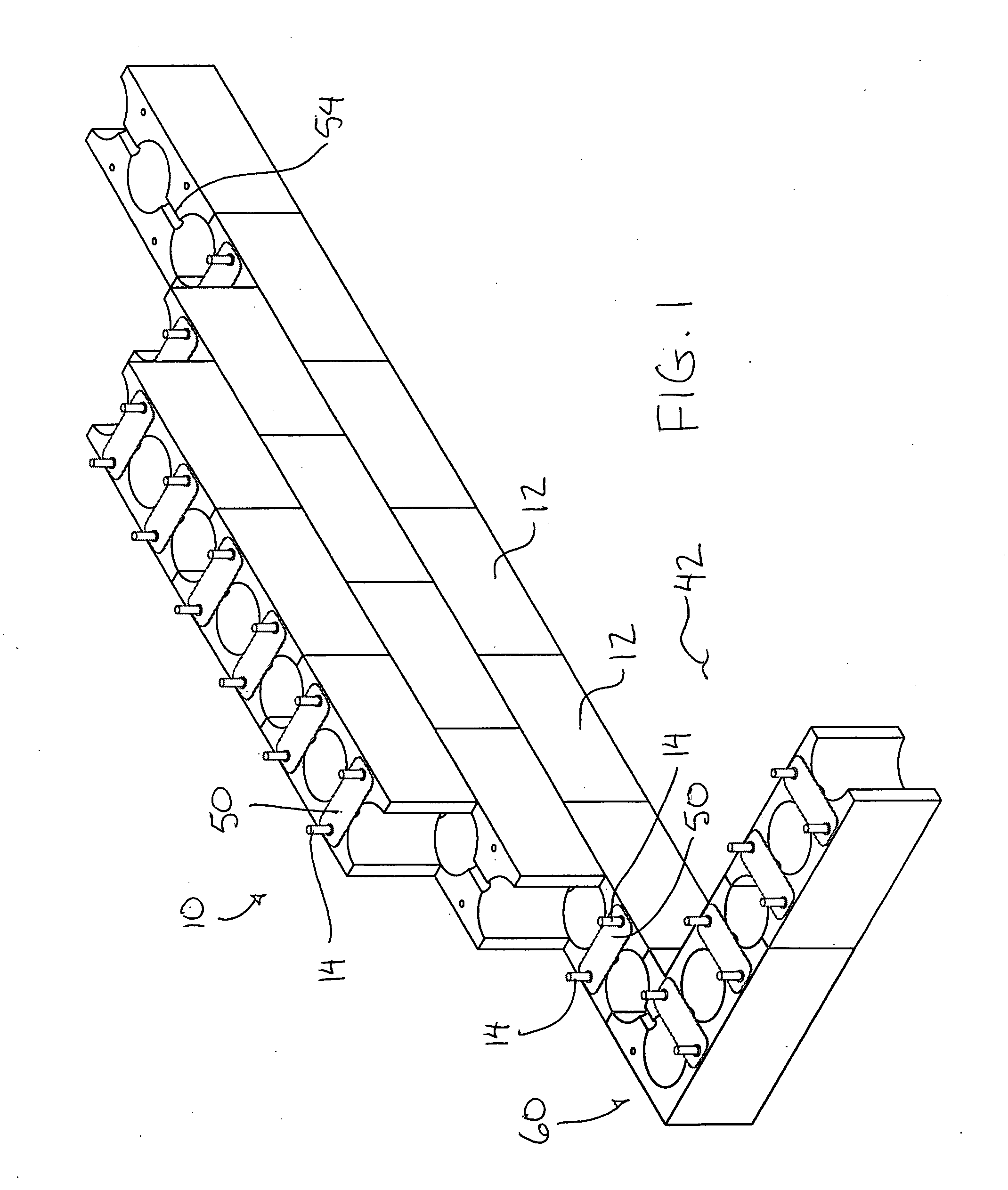

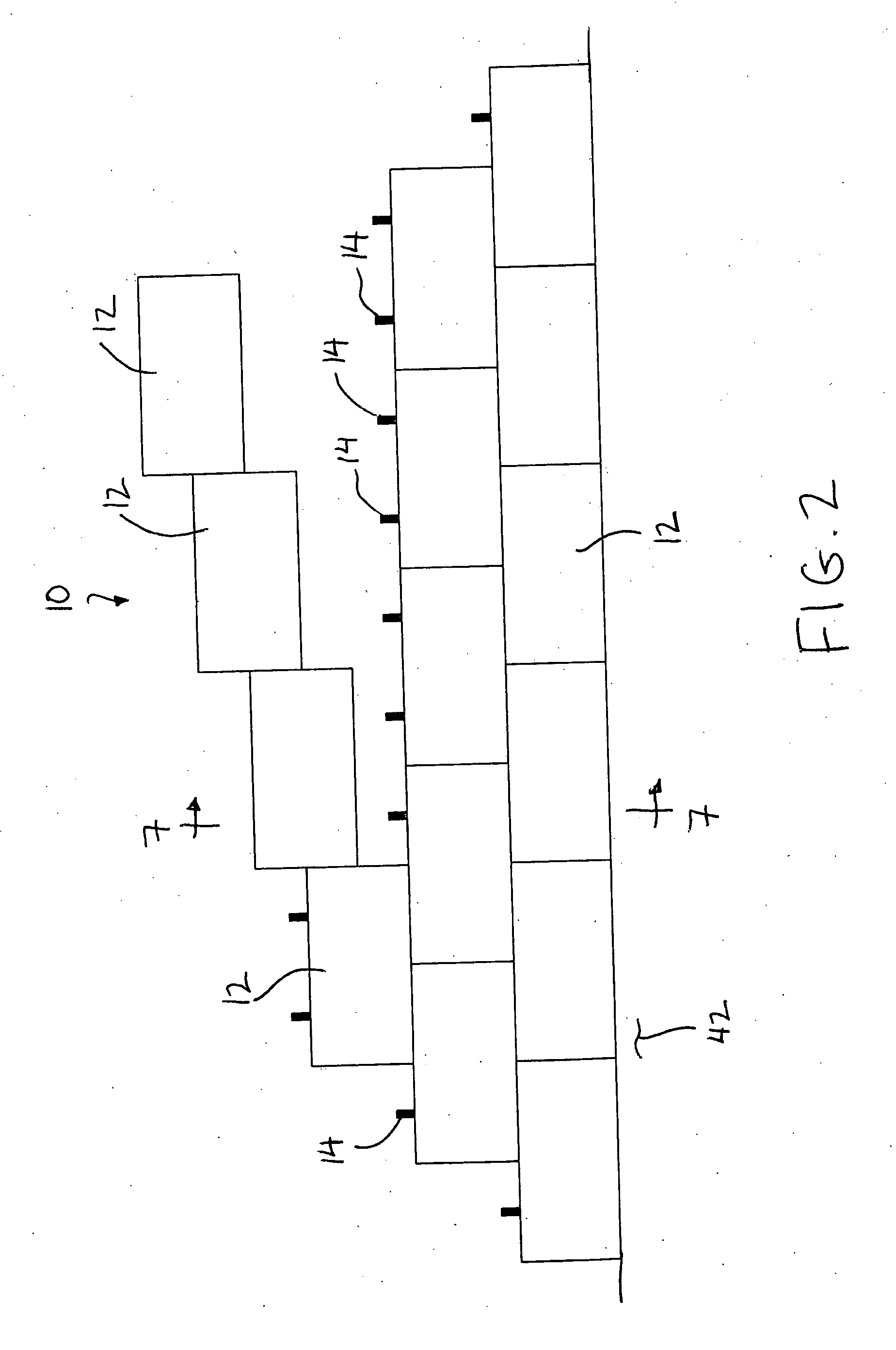

[0071] Referring to the accompanying figures there is illustrated a masonry wall system generally indicated by reference numeral 10. The system 10 includes a plurality of masonry blocks 12 which are mechanically coupled to one another using masonry fasteners 14 as described herein.

[0072] Each masonry block 12 comprises a rectangular body of pre-cast concrete which is elongate in a longitudinal direction between opposing ends 16 of the body. The height and width in a lateral direction perpendicular to the longitudinal direction are approximately equal to one another, having dimensions each of approximately 200 millimetres while the length is approximately double. The blocks each include opposing, upright and flat side walls 18 extending longitudinally between the ends and which form the surfaces of the wall structure being formed when the blocks are stacked on top of one another. Each block also includes a flat top side 19 and a flat bottom side 20 which permits stacking of the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com