Hybrid evaporator

a hybrid evaporator and evaporator technology, applied in indirect heat exchangers, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of cooling capacity decline, non-uniform air temperature distribution, and further exacerbated non-uniform discharge air temperature in such evaporators, so as to reduce the drop in pressure and maximize the surface area of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

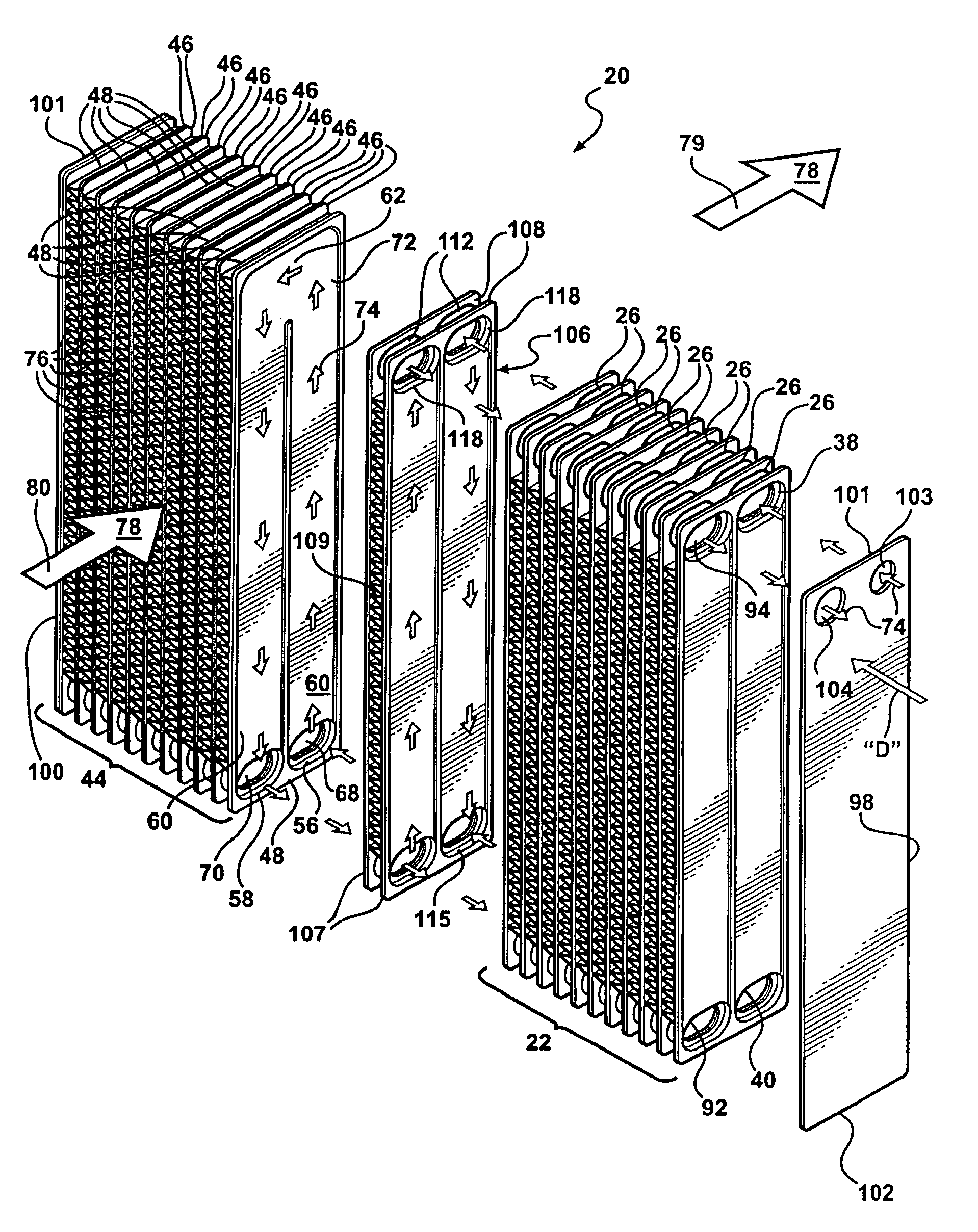

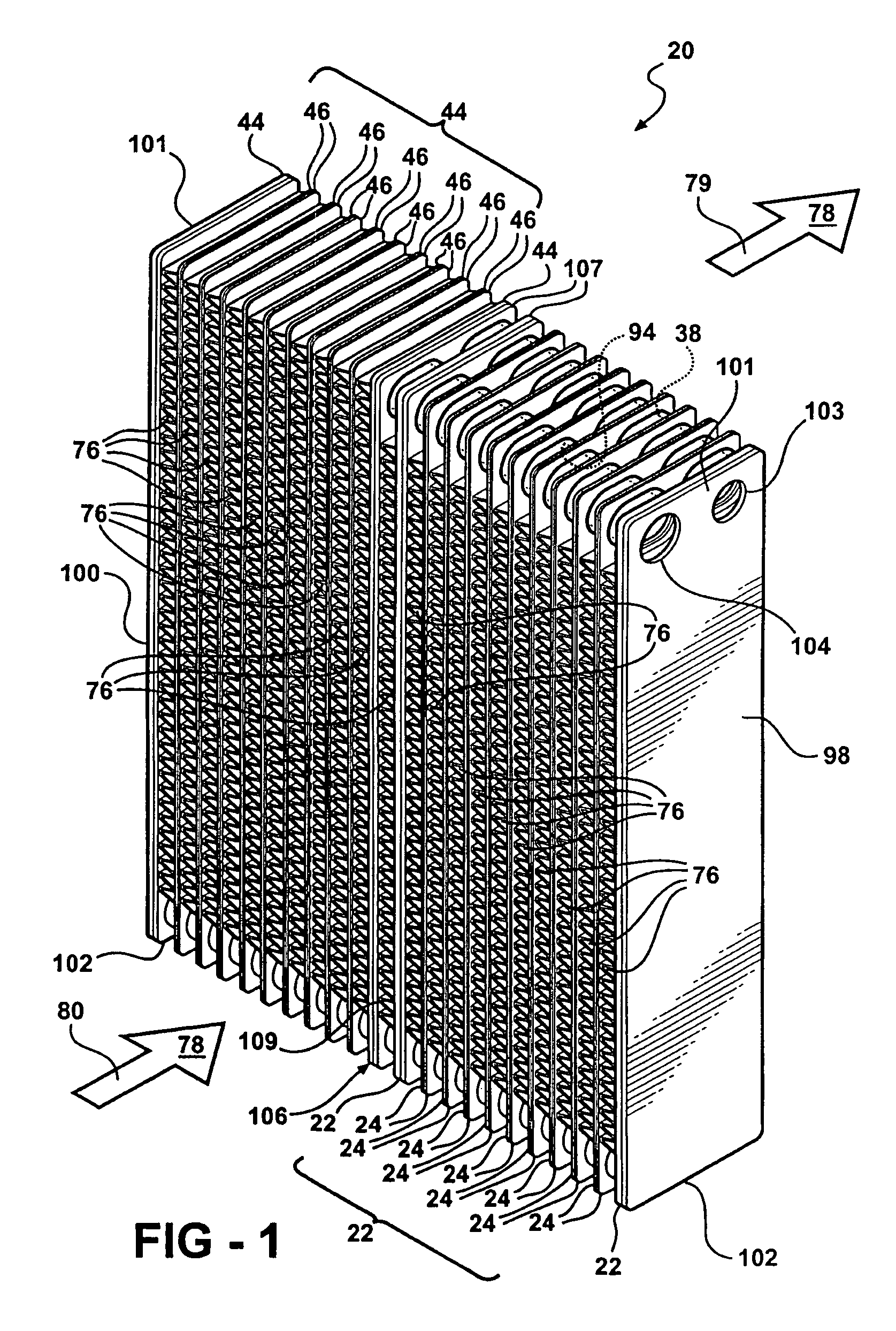

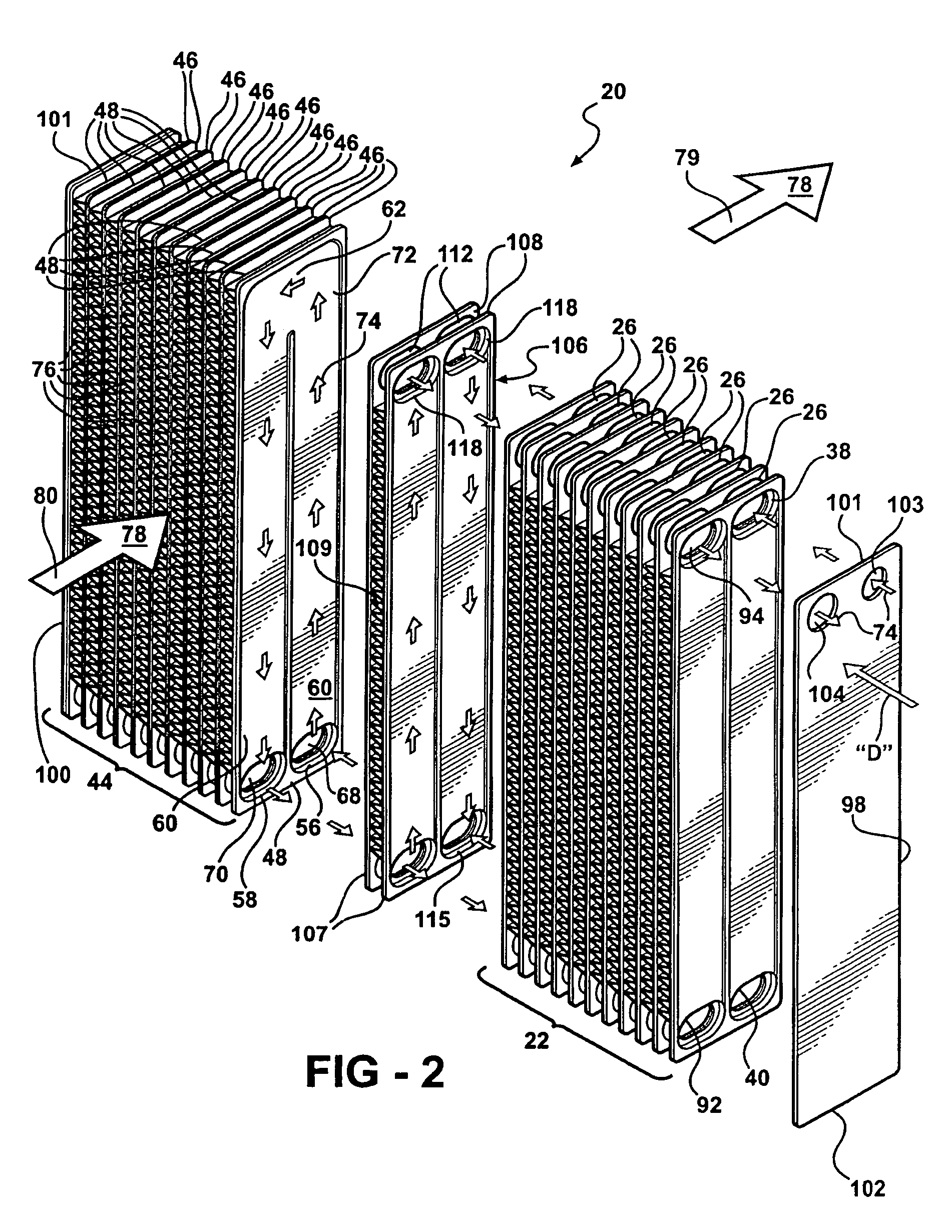

[0024] Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a laminate-type evaporator is generally shown at 20 in FIGS. 1 through 3. The evaporator 20 includes a plurality of first tube plates 22 (dual cup tube plates) stacked together in adjacent pairs 24. As is best shown in FIG. 4, each first plate 22 includes first and second tubular projections 26, 28 and a first recess 30. The first plate 22 also has an exterior surface 32. The first recess 30 extends between the first and second tubular projections 26, 28. The first and second tubular projections 26, 28 define respective apertures 34, 36 through the plate 22. The projections 26, 28 also extend from the plate 22 in the same direction as the first recess 30.

[0025] Referring to FIGS. 1 and 2, the adjacent pairs 24 are positioned in abutting engagement with one another such that the first tubular projections 26 define a first tank 38 and the second tubular projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com