Cover or wall profile

a technology of cladding profile and section system, which is applied in the direction of covering/lining, floor covering, buildings types, etc., can solve the problem that the installers do not correctly install the earlier described profile system, and achieve the effect of preventing damage or buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

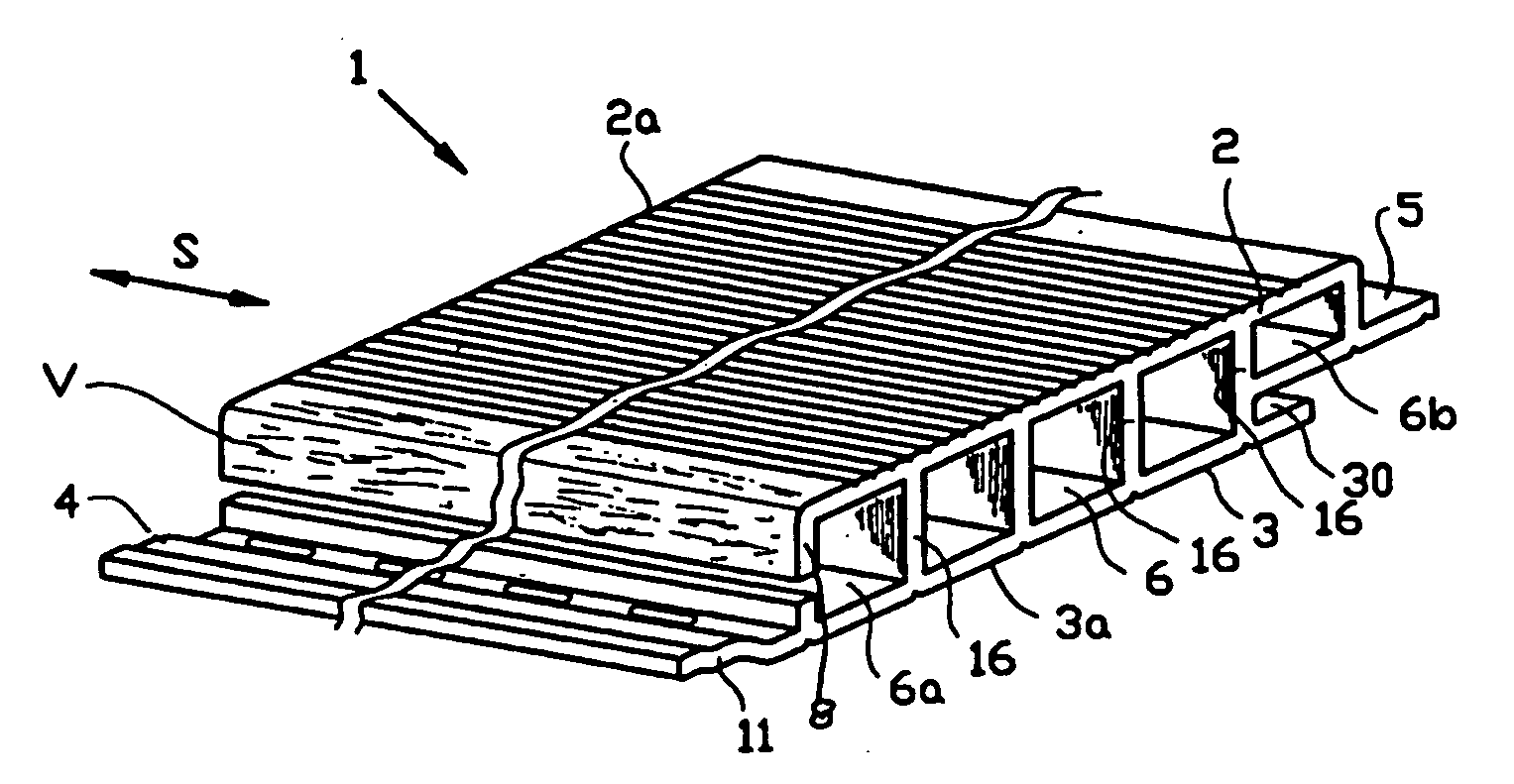

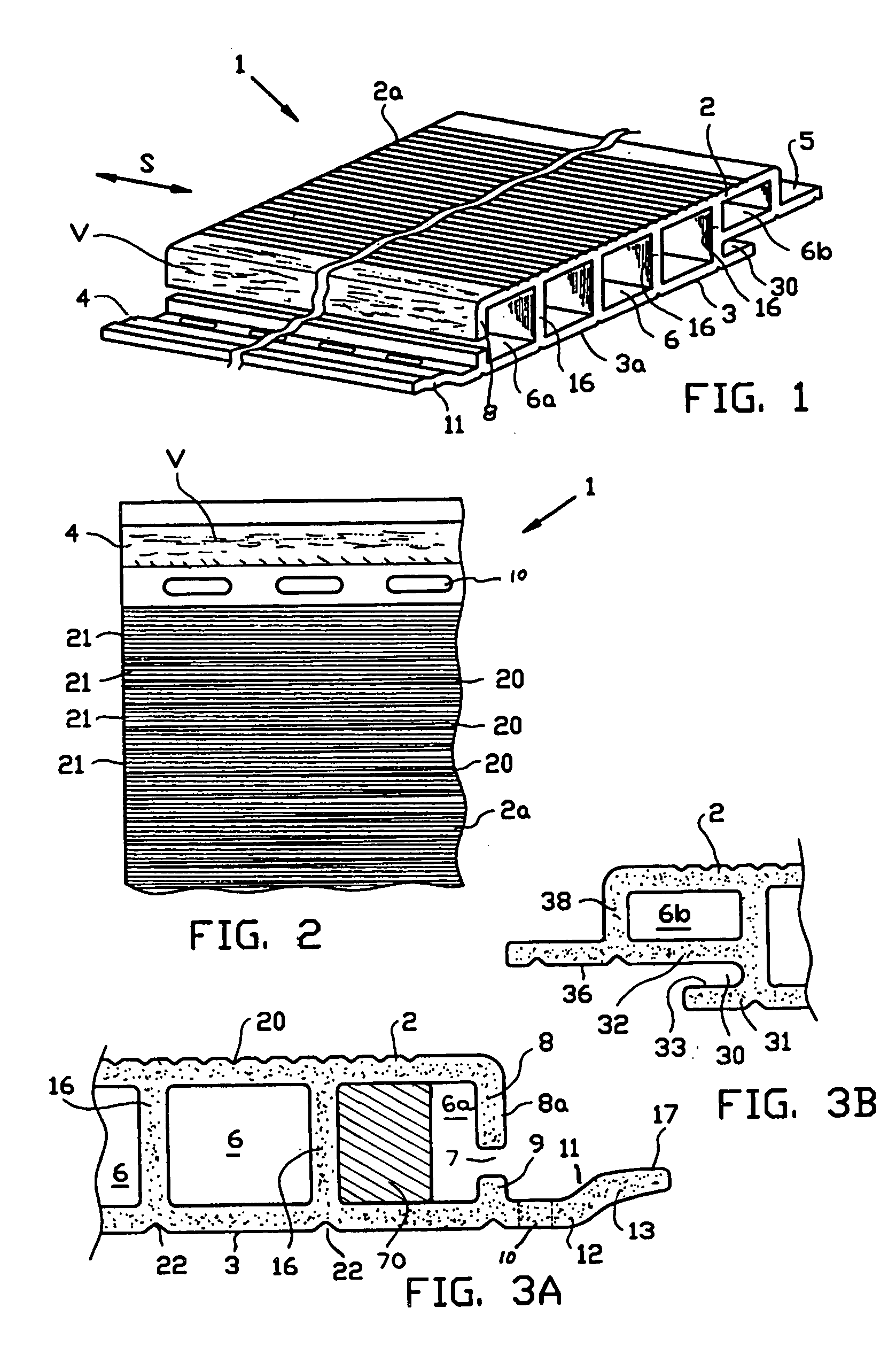

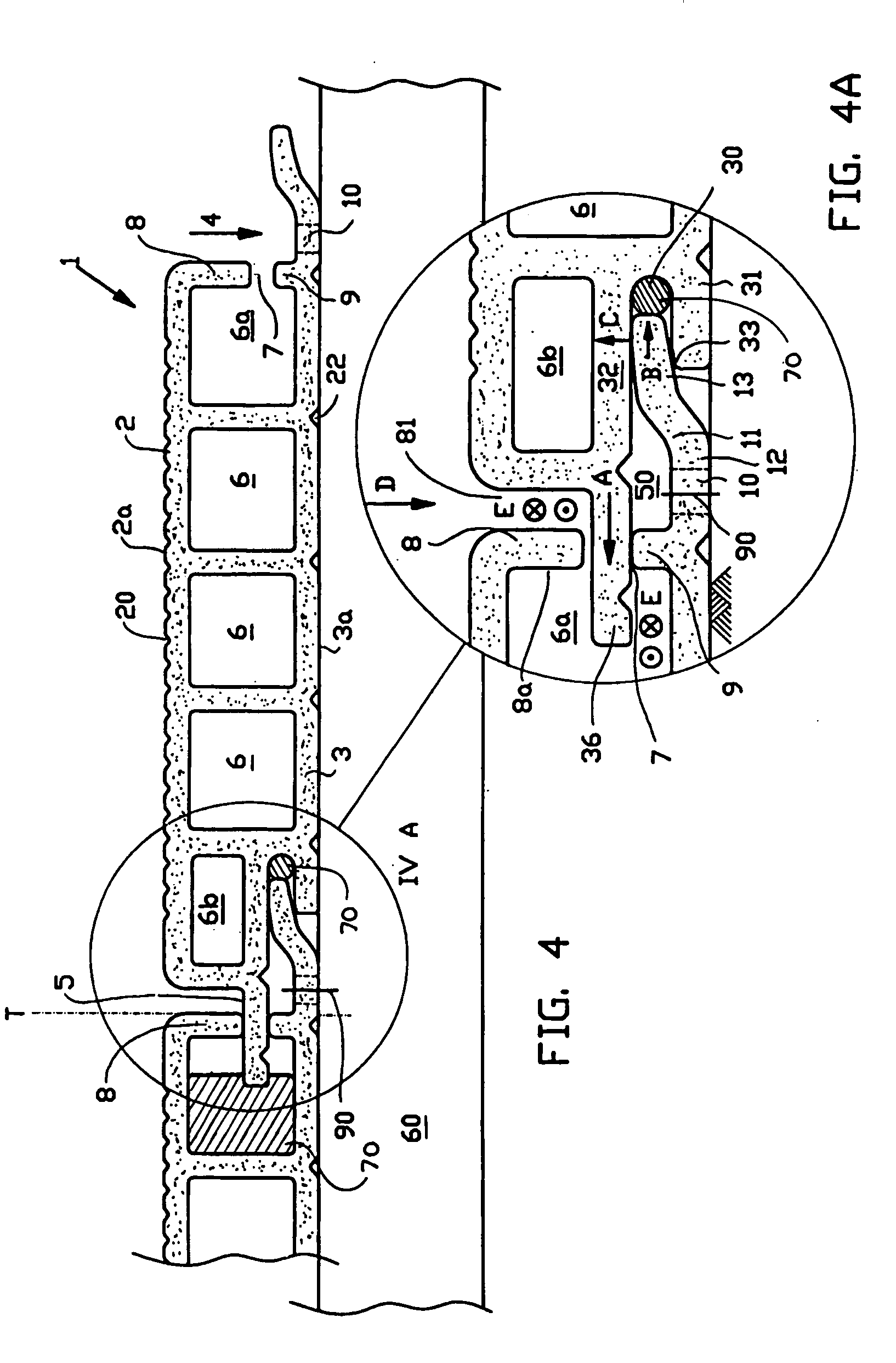

[0050] The profile part or profile member 1 is shown in FIG. 1 and further, is manufactured by an extrusion or pushtrusion process in direction S, and is formed from a composite material, comprising a matrix of synthetic thermoplastic polymer, particularly a polyolefin, preferably polypropylene, including a plurality of, for instance 70% by weight or more, preferably 70 to 80% by weight of a mixture of short wood fibres and long wood fibres, wherein the short wood fibres have a length in the range of 0.2-2 mm and the long fibres are in the range of 2-8 mm, preferably 4-6 mm. In a manner as for instance described in U.S. Pat. No. 6,929,841, the long fibres V during manufacturing have been oriented substantially in direction S, whereas the short fibres are randomly oriented. During production of the profile part 1, use is made of dried wood fibre material that contains moisture content less than 1%, preferably less than 0.5% by weight.

[0051] In the embodiment of a hollow profile, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com