Flexible package having insulating support member

a flexible packaging and support member technology, applied in the field of flexible packaging, can solve the problems of unable to provide structural support to flexible bags, the heat loss of food products in such bags may be rapid to the surrounding environment, and the insulation value of food products is small to no

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

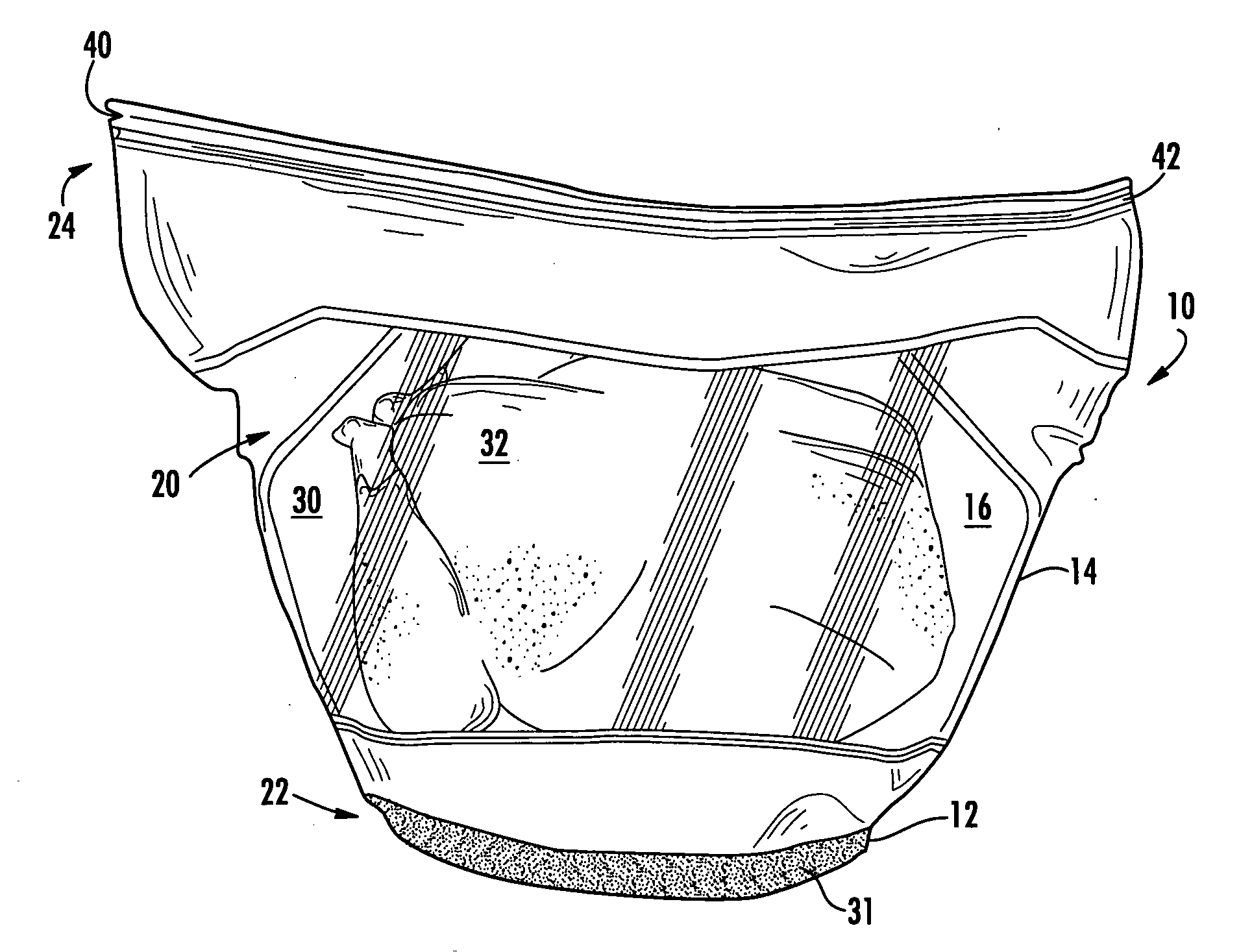

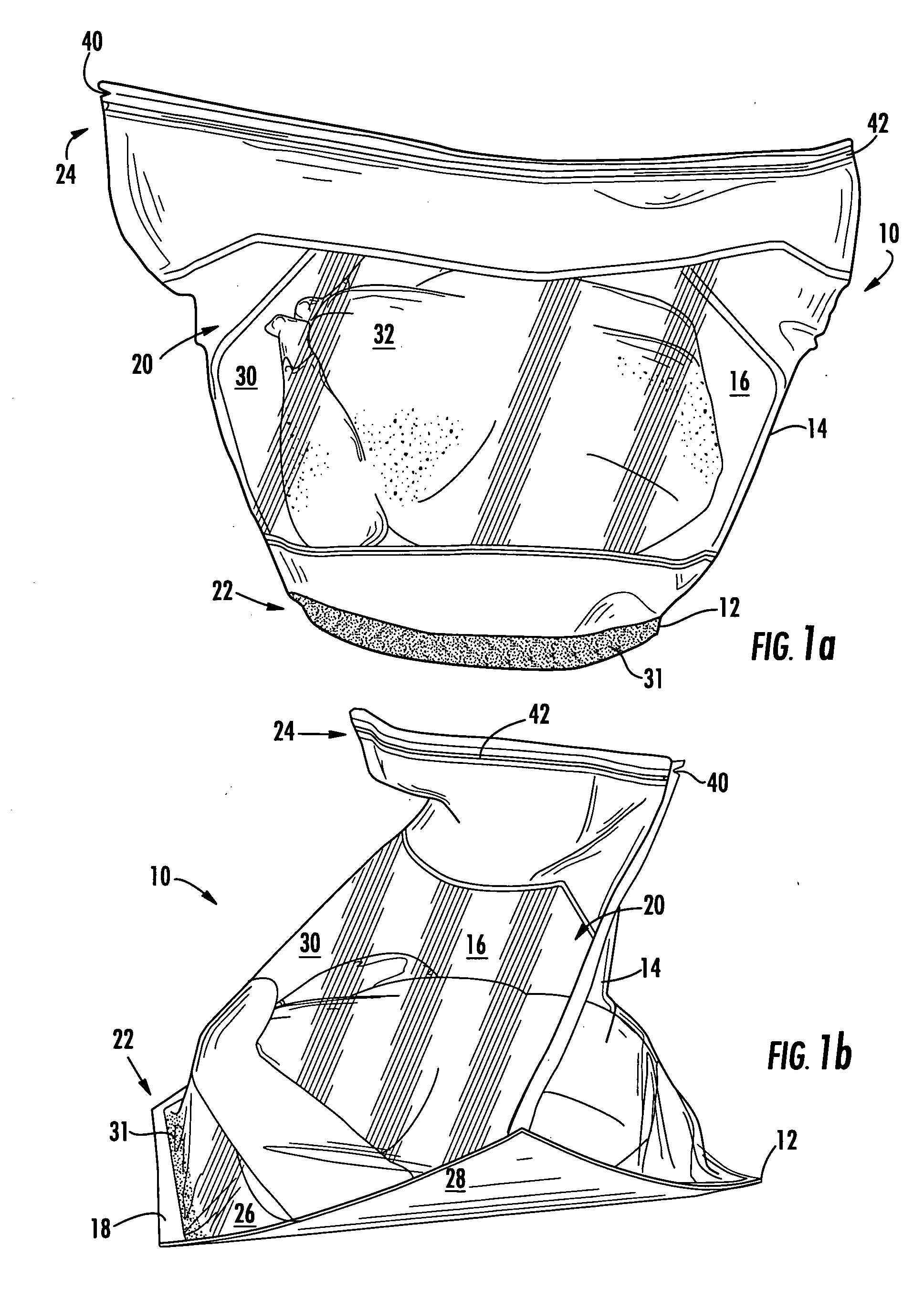

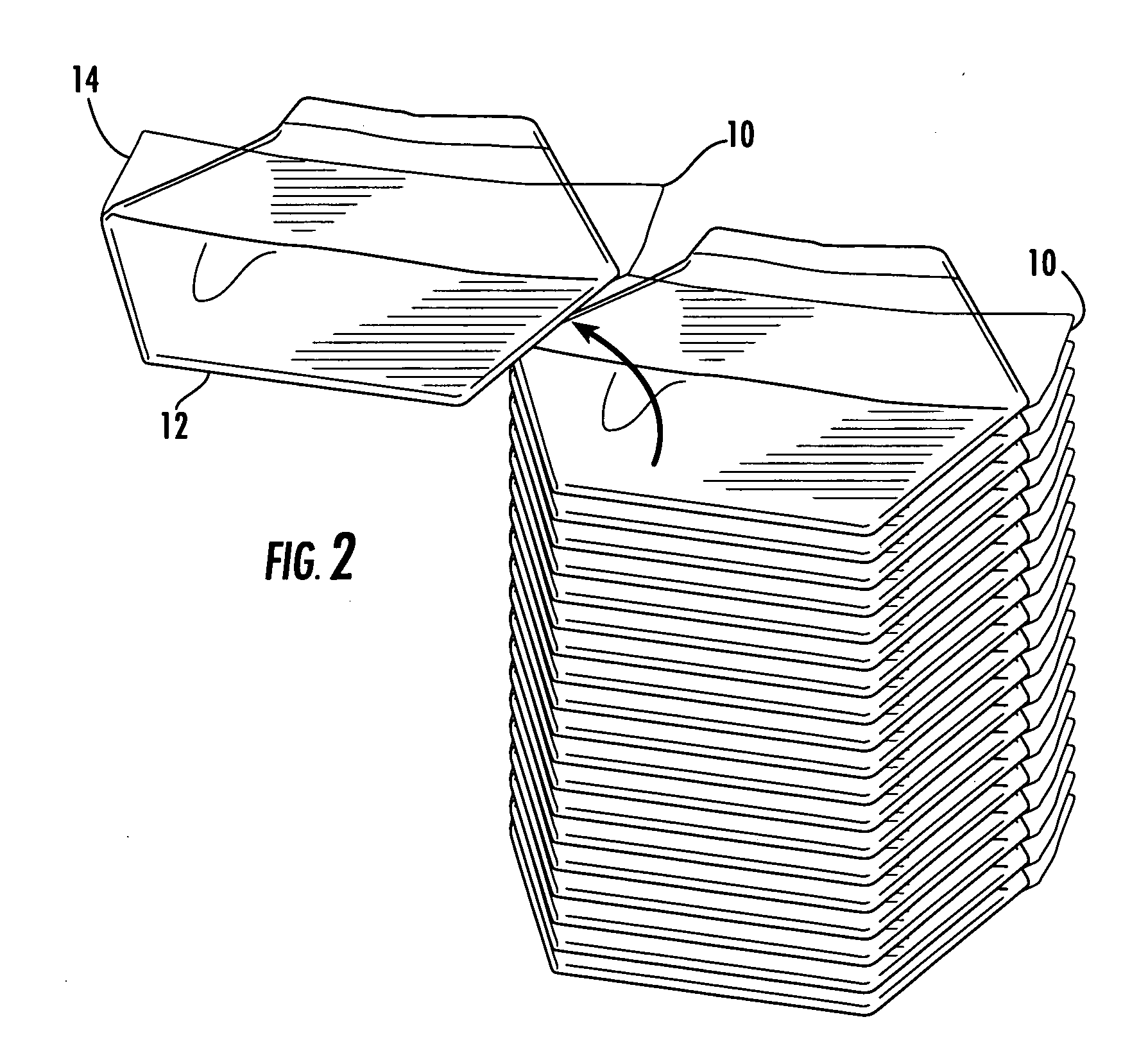

Image

Examples

example 1

[0064] In this example, the insulating properties and hot handling properties of the support member were compared to the insulating properties of a small paperboard box, such as the type commonly used in deli applications for packaging and carrying home a heated food product. Two samples of simmering water having a temperature of approximately 201° F. were placed in a flexible package of the invention comprising polypropylene foam and having a density of 0.45 g / cc, and the paperboard box. The paperboard box and the polypropylene foam both had a thickness of 0.018 inches.

[0065] After the water samples were placed in their respective test containers, the two containers were handled to determine the relative insulating capabilities of each container. The paperboard container could only be handled briefly before the container was too hot for further handling. The flexible package of the invention could be handled on the order of 30 seconds before the package was considered too hot for ...

example 2

[0067] In another experiment, the hot handling capabilities of a flexible pouch having a support member comprising a layer of air cellular material that included 1 inch sidewalls extending upwardly on the continuous sidewalls of the flexible package. Simmering water having a temperature of about 180° F. was introduced into the pouch. Thereafter, the bottom of the flexible package was held to determine the insulating capacity of the flexible pouch. The flexible pouch was able to be continuously handled without becoming too hot to handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com