Dehydration control apparatus and method for washing machine

a control apparatus and washing machine technology, applied in the field of washing machines, can solve the problems of noise and vibration, reduced motor speed, and serious vibration and noise in the dehydration operation, and achieve the effects of reducing the dehydration entering time, increasing or decreasing the dehydration speed, and restricting noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0037] A dehydration control apparatus and method for a washing machine which can restrict noise and vibration resulting from mis-application of a reference unbalance quantity and reduce a dehydration time, by sensing variations of a dehydration quantity and applying different reference unbalance quantities according to the varied load quantities will now be described in detail with reference to the accompanying drawings.

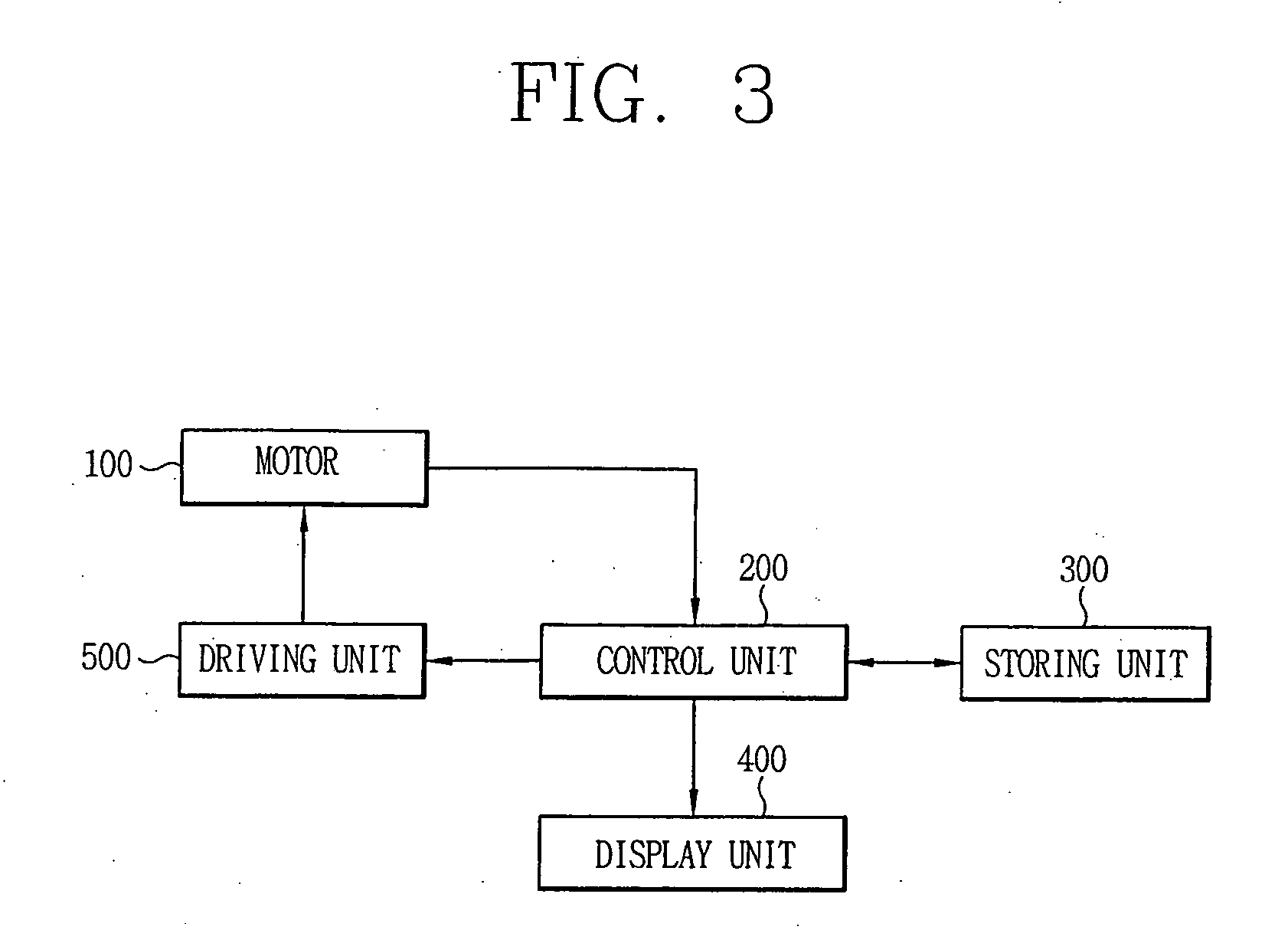

[0038]FIG. 3 is a block diagram illustrating the structure of the dehydration control apparatus for the washing machine in accordance with an embodiment of the present invention.

[0039] In FIG. 3, the dehydration control apparatus for the washing machine includes a motor 100, a driving unit 500, a storing unit 300, a display unit 400 and a control unit 200.

[0040] The motor 100 rotates a wash tub in the washing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com