Heat exchanger with modified diffuser surface

a technology of heat exchanger and diffuser, which is applied in the direction of heat exchange apparatus, heat transfer modification, light and heating equipment, etc., can solve the problems of reducing heat exchange efficiency, reducing resistance to thermal fatigue, and often affecting the shape of packaging constraints, so as to improve the gas flow and thermal transfer efficiency of the heat exchanger, and minimize the formation of macro-boundary layers. , the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention relates to heat exchangers used for reducing the temperature of an entering gas or fluid stream. The particular application for the heat exchangers of the present invention is with vehicles and, more particularly, to cool an exhaust gas stream taken from an internal combustion engine. However, it will be readily understood by those skilled in the relevant technical field that heat exchanger constructions of the present invention as described and illustrated herein are understood to be used in a variety of different applications, and thus the invention disclosed herein should not be limited to such applications

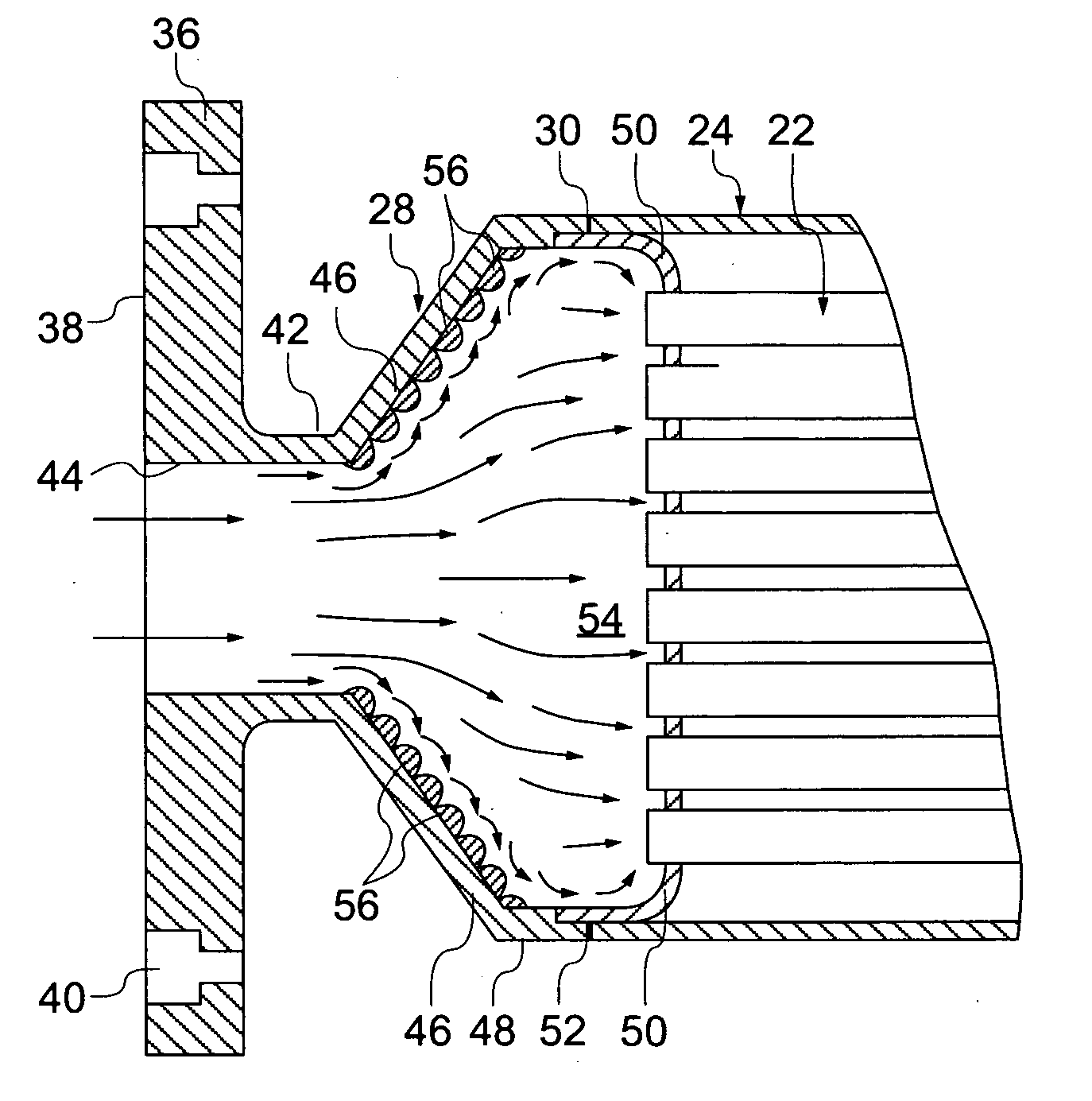

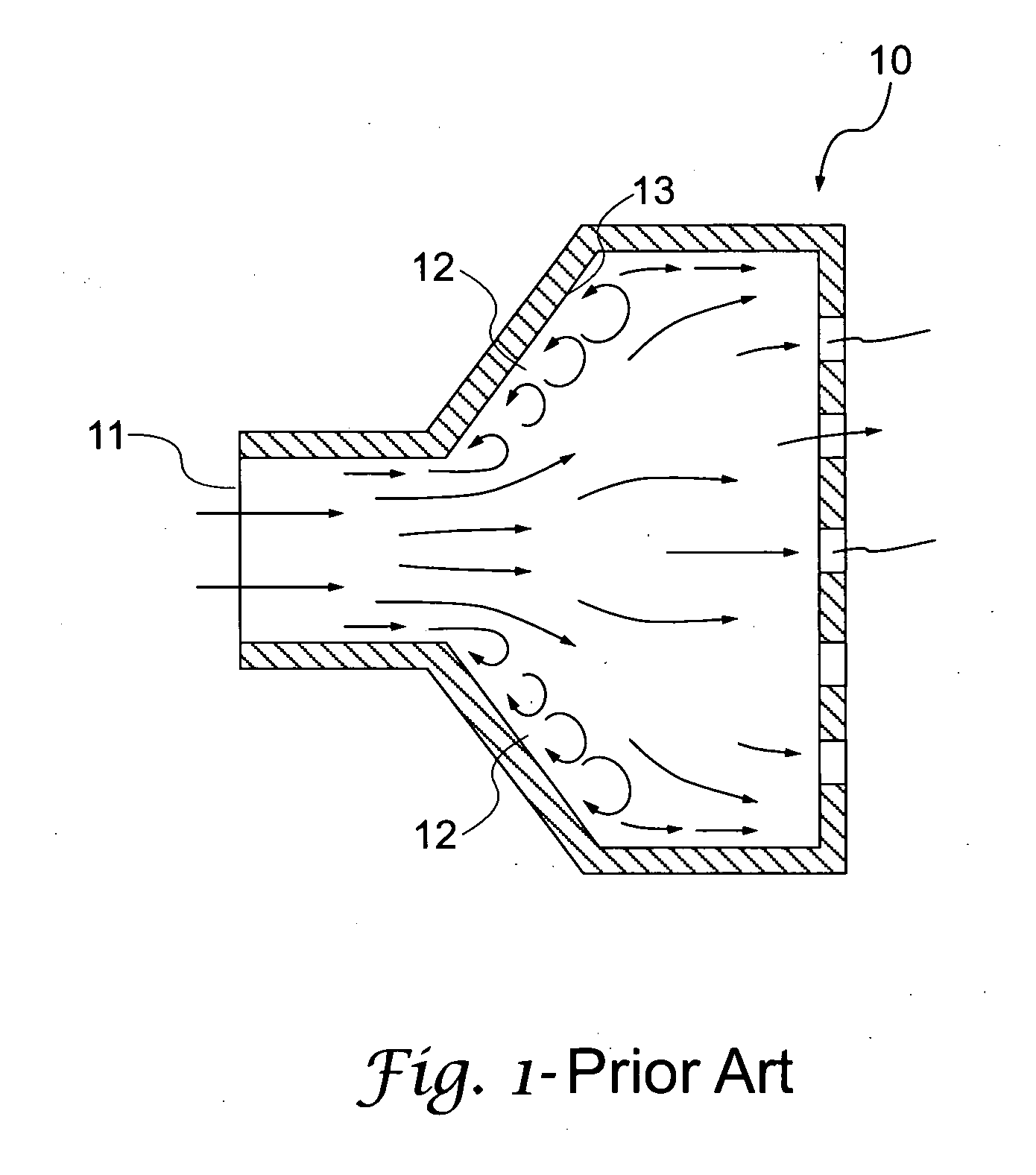

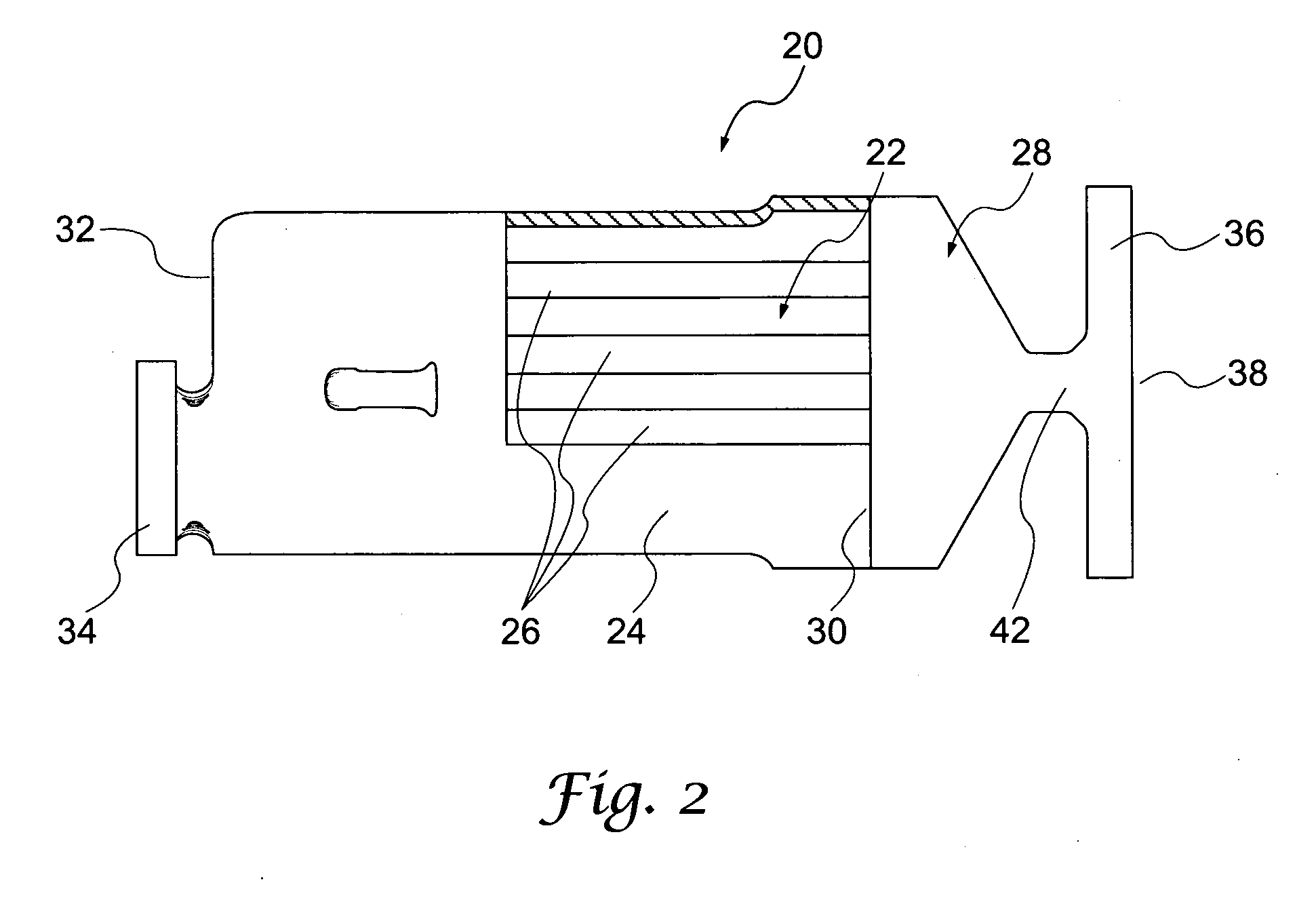

[0021] Generally, heat exchangers constructed in accordance with principles of this invention include a diffuser that has been specially engineered to have an inside wall surface configured with a plurality of surface features that are use to reduce or eliminate unwanted boundary layer separation of gas within the diffuser during heat exchanger ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com