Methods and apparatuses relating to block receptor configurations and block assembly processes

a technology of block receptors and configurations, applied in the field of fabrication openings, can solve the problems of increasing the number of ics to be packaged, presenting problems that the overall process has to overcome, and improving the efficiency or yield of the receptor site filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

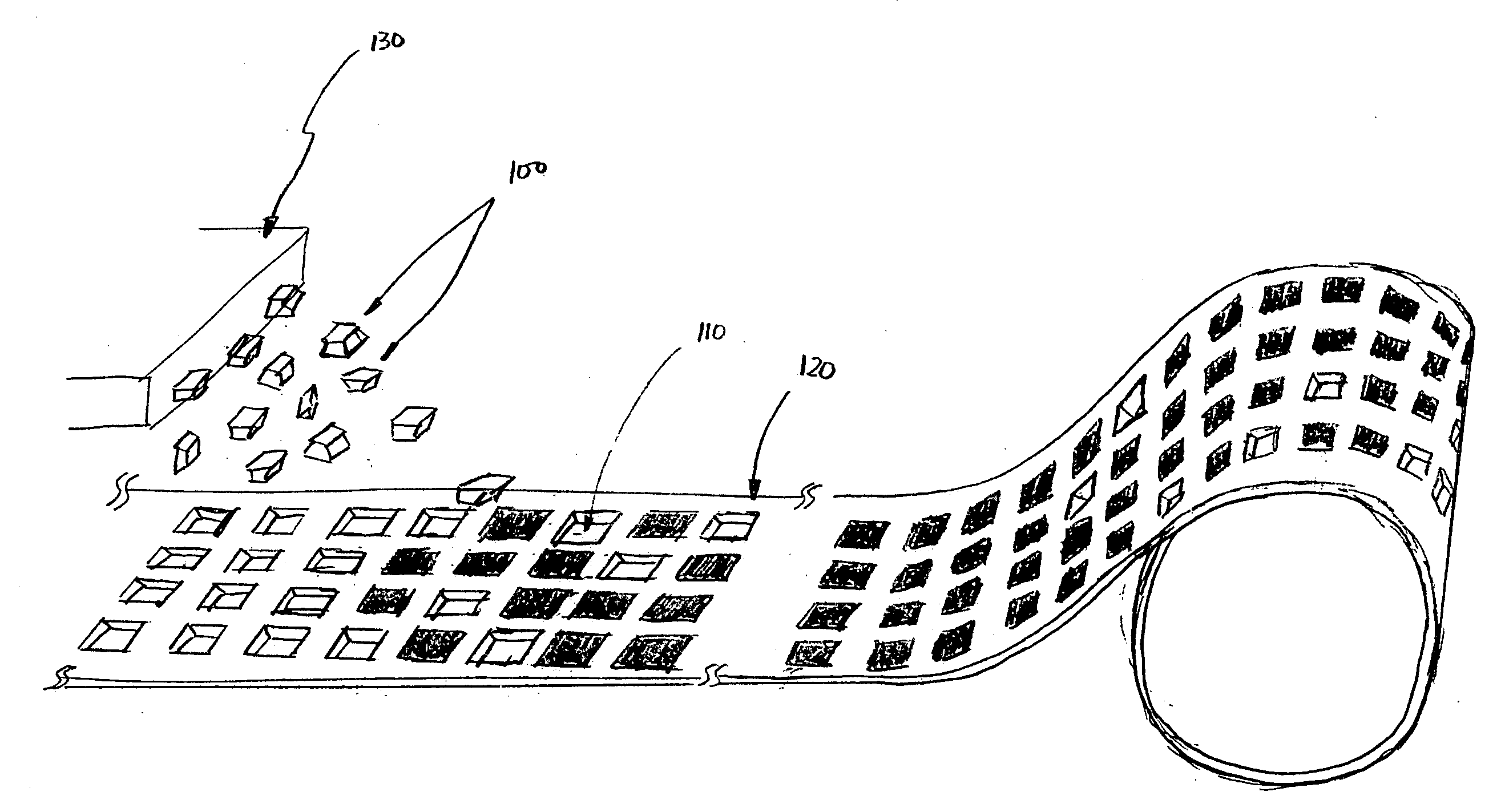

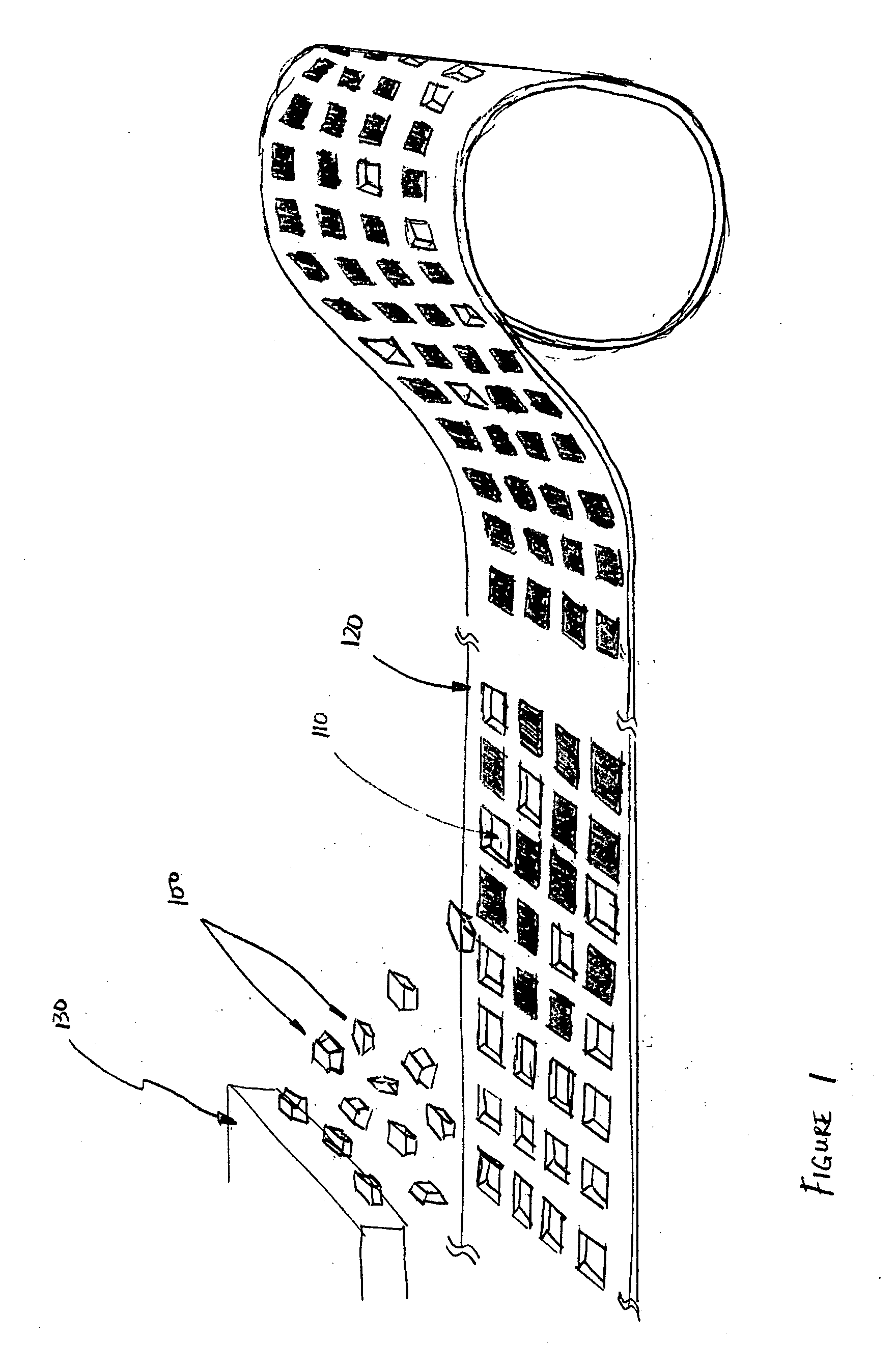

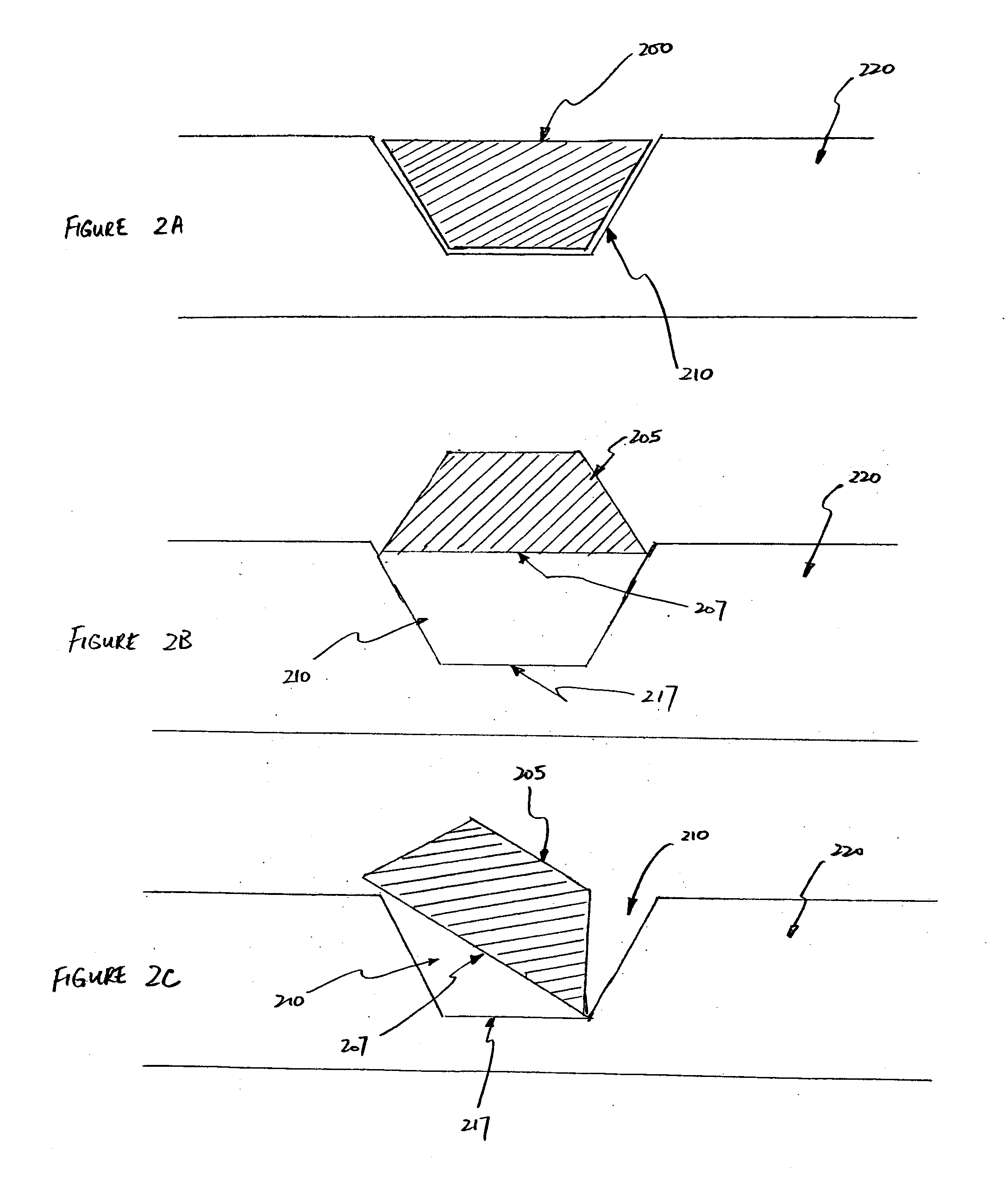

[0045] The present invention relates to apparatuses and methods for shaping receptor openings to improve the efficiency of depositing functional elements into an array of receptor sites in a receiving substrate, or a long web of repeated substrate elements, via a FSA process. The following descriptions and drawings are illustrative of the invention by example and are not to be construed as limiting the invention. Numerous details are described to provide a thorough understanding of the present invention. In certain instances, well-known or conventional details are not described in order to not unnecessarily obscure the present invention in detail.

[0046] The present invention relates generally to the field of shaping openings in a receiving substrate and to apparatuses having these openings. The present invention may be used to shape openings for different types of arrays. Generally an element in an array includes a functional component that may include an electrical component, a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com