Four parts manhole enabling an easy install and height adjustment

a manhole and height adjustment technology, applied in the field of easy installation and height adjustable manholes, can solve the problem that no prior art teaches the concept of providing a height adjustable manhole system, and achieve the effect of convenient adjustment and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

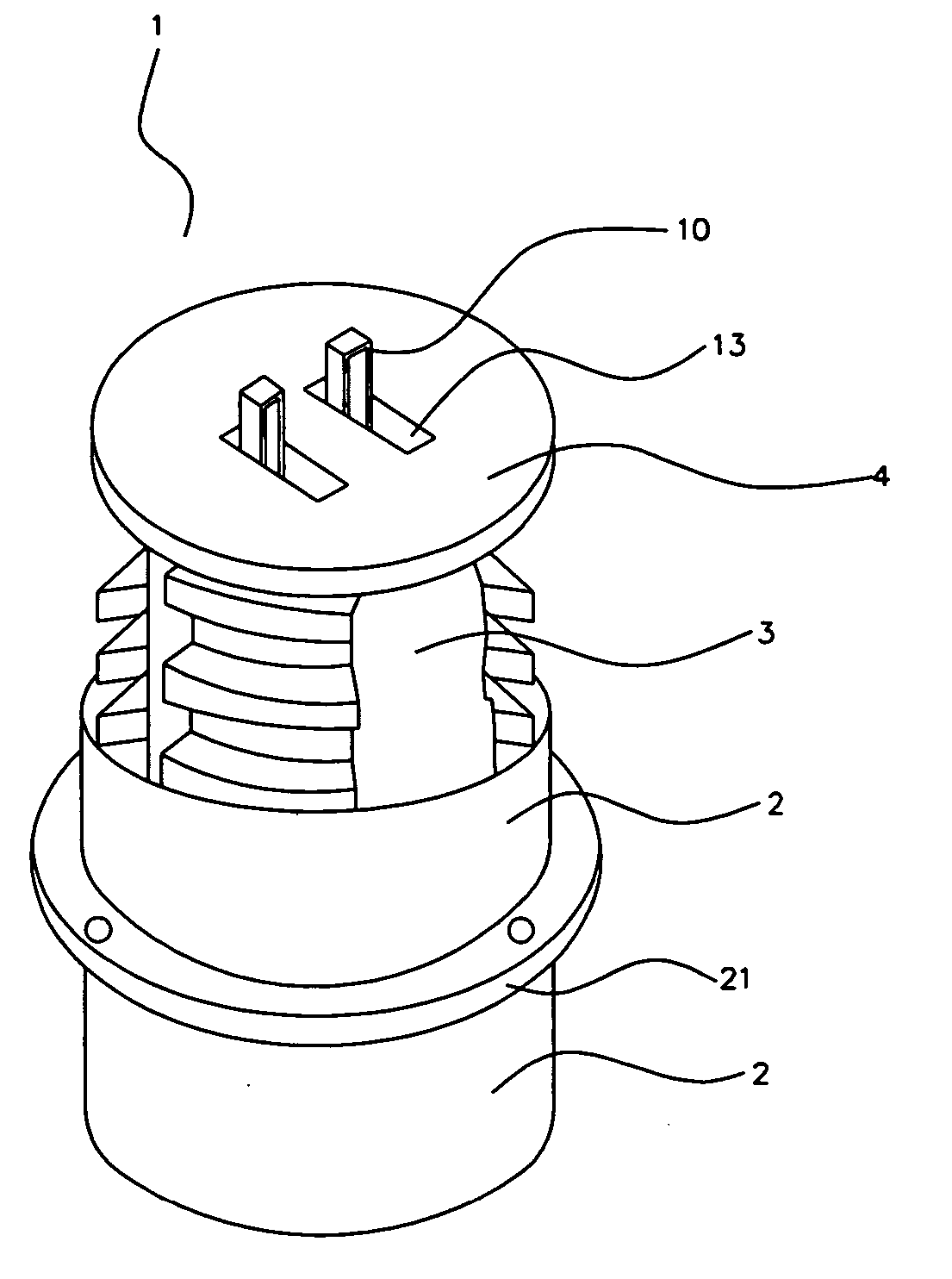

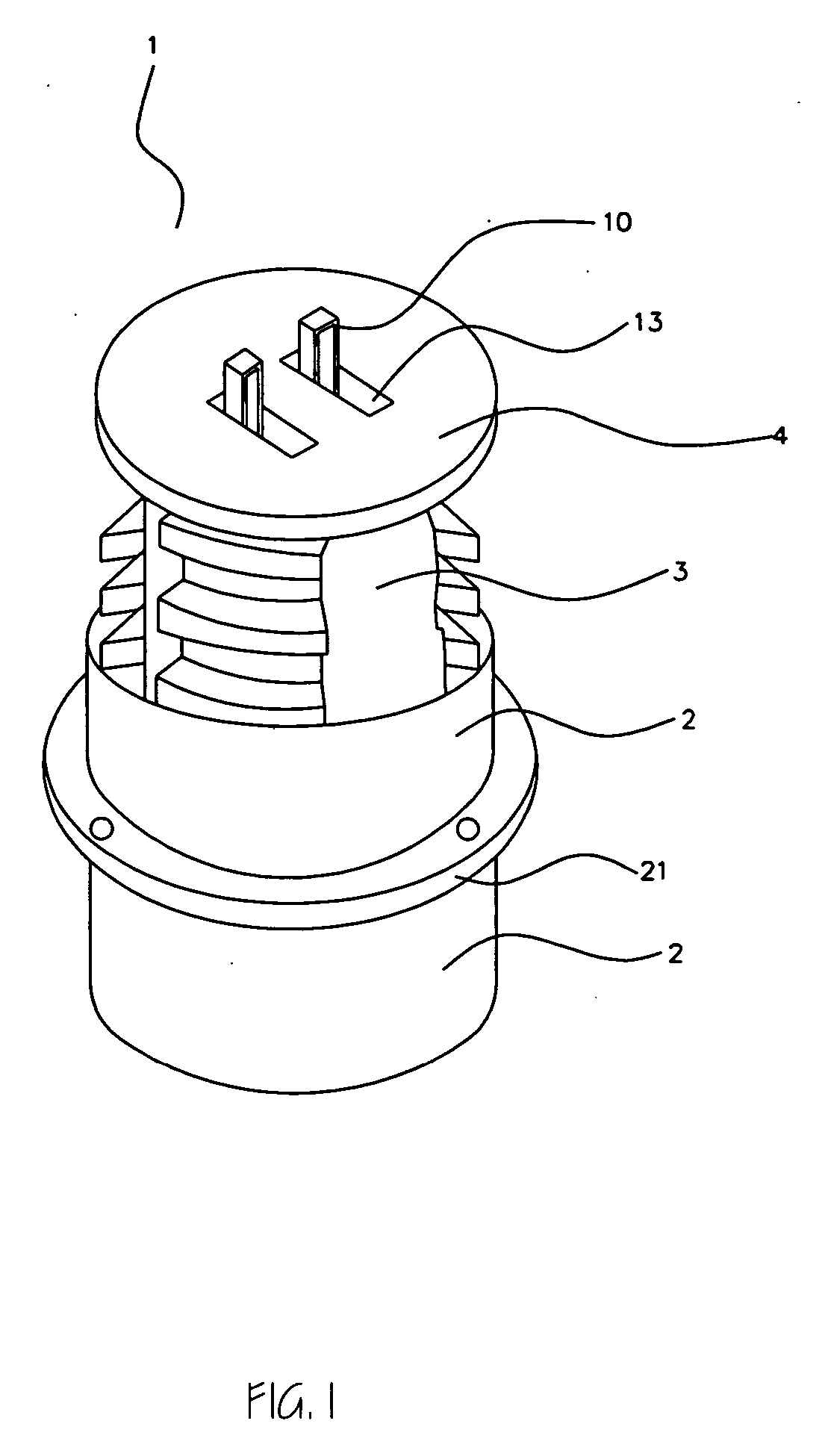

[0024]FIG. 1 is a perspective view of a height adjustable manhole (1) of the current application. The manhole (1) is comprised of an outer-manhole pipe (2), an inner-manhole pipe (3), a manhole cover (4), and a support pipe (5).

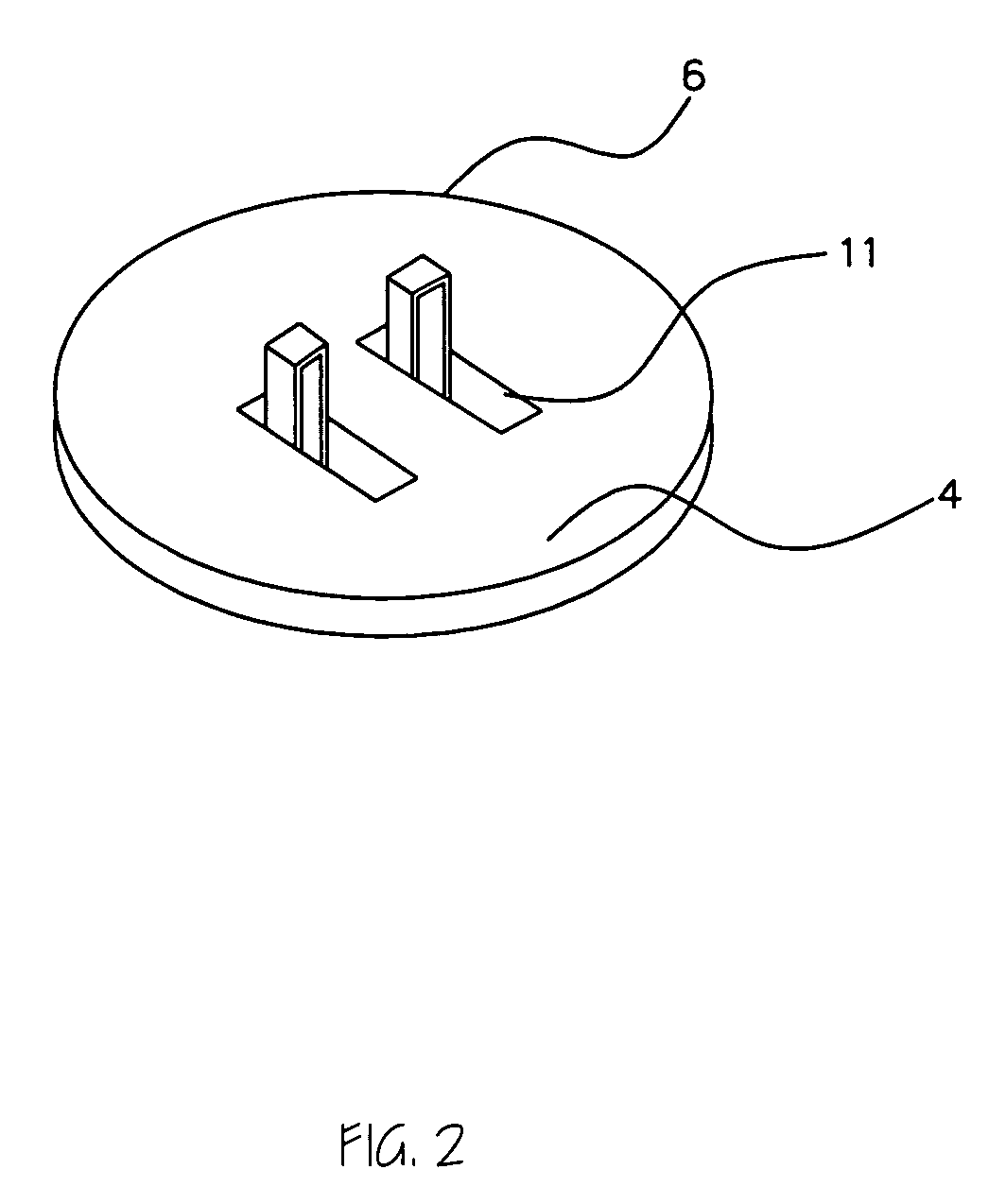

[0025]FIG. 2 is a perspective view of a manhole cover (4) with handle cam lock (6) for the height adjustable manhole (1) of the current application. FIG. 3 is a perspective view of a cam lock (6) of the manhole cover (4). FIG. 4 is a perspective view of an inner- manhole pipe (3) equipped with a flange (7). The flange (7) has an opening (8) to receive cam shaft (9). When the handle (10) of the cam lock (6) is vertically upward, the cam shaft (9) is placed in down part of the cylindrical cam hole (11) due to the shape of cam (12). When the handle (10) of the cam lock (6) is laid down and inserted into the cam lock box (13), the camshaft (9) is placed in the upper part of the cam hole (11).

[0026] To close the manhole cover (4), a worker picks up the handle (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com