Plasma display device with heat sink noise reducer

a display device and heat sink technology, applied in the direction of instruments, gas discharge vessels/containers, electrical devices, etc., can solve problems such as noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

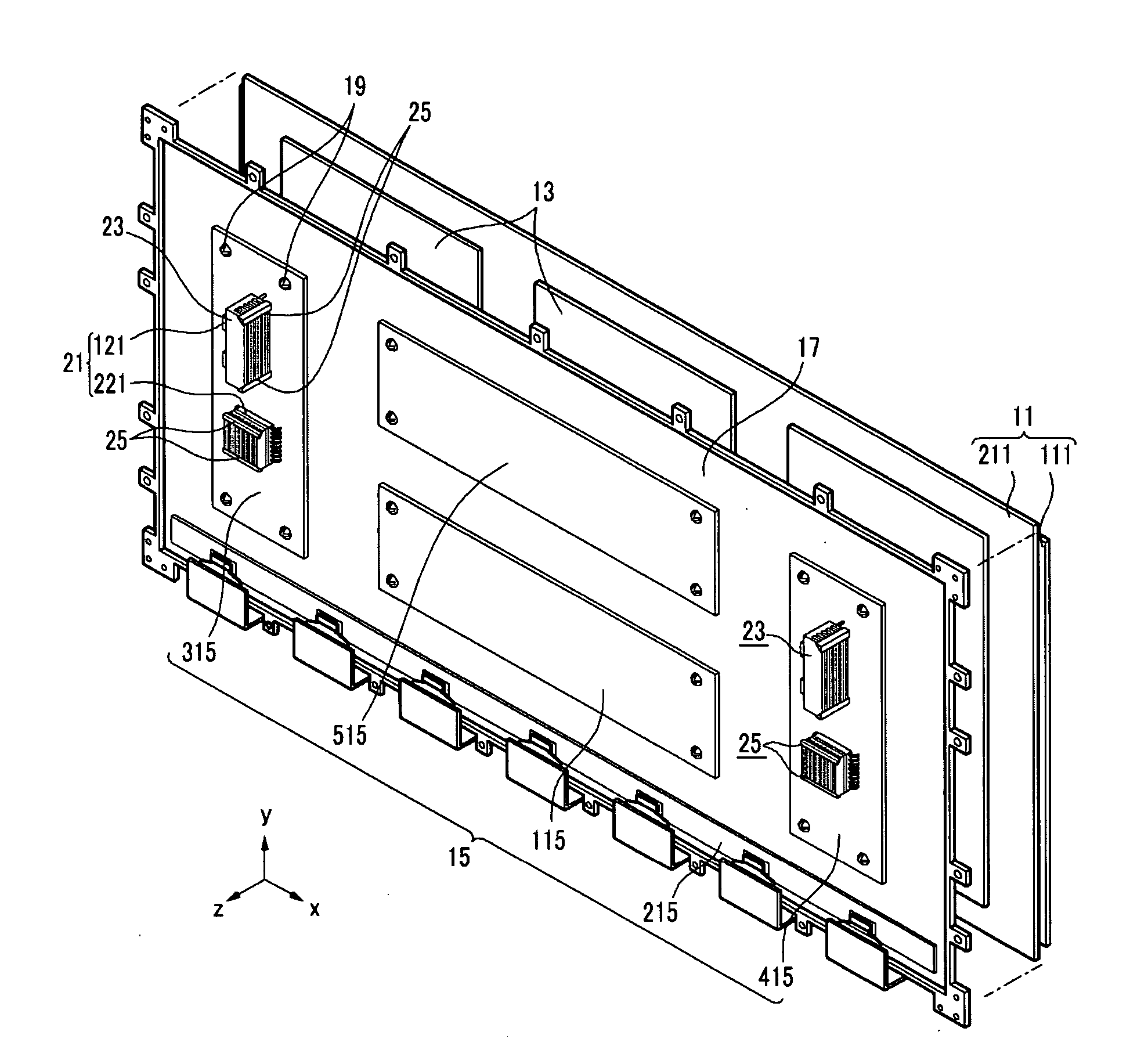

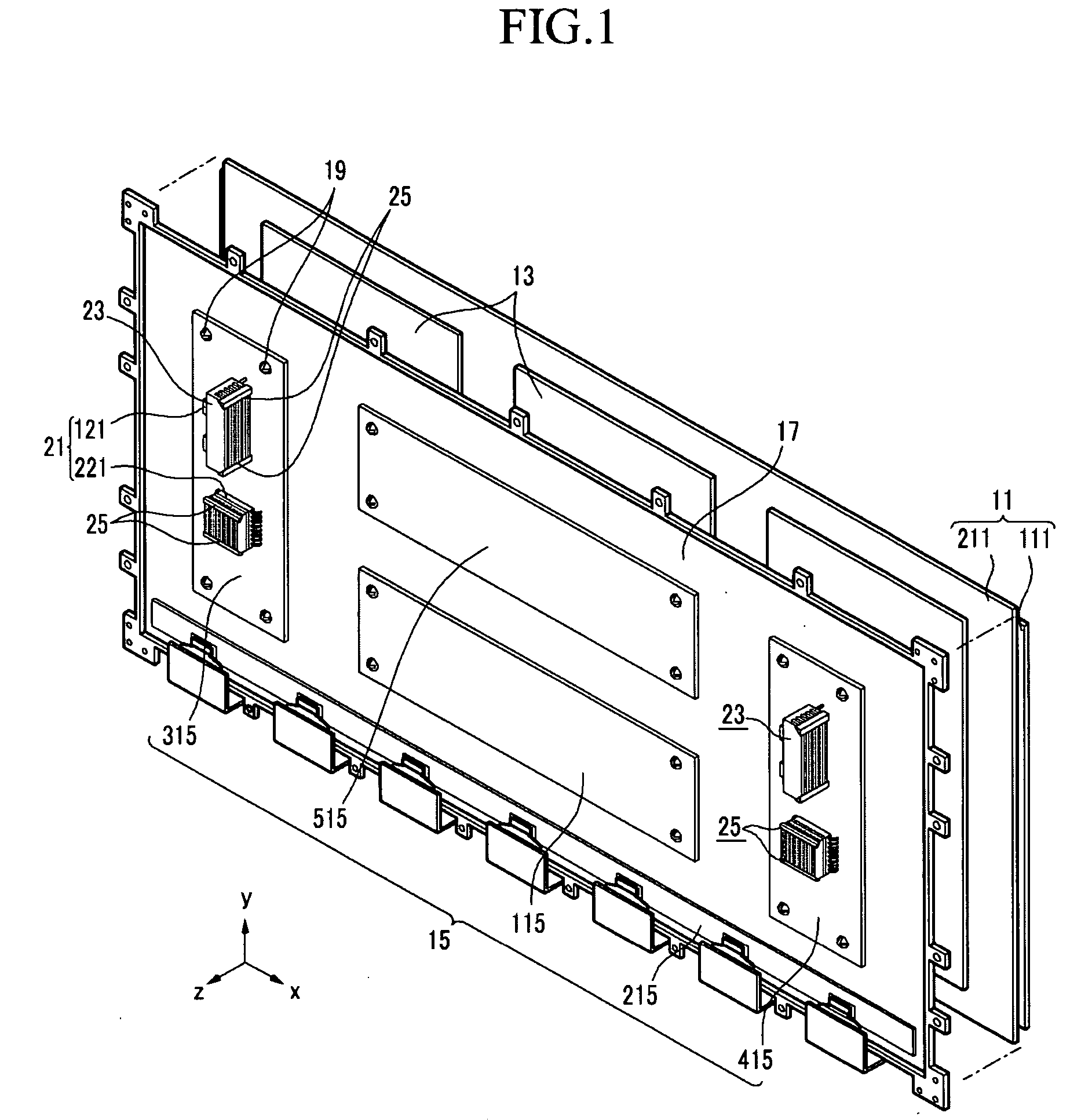

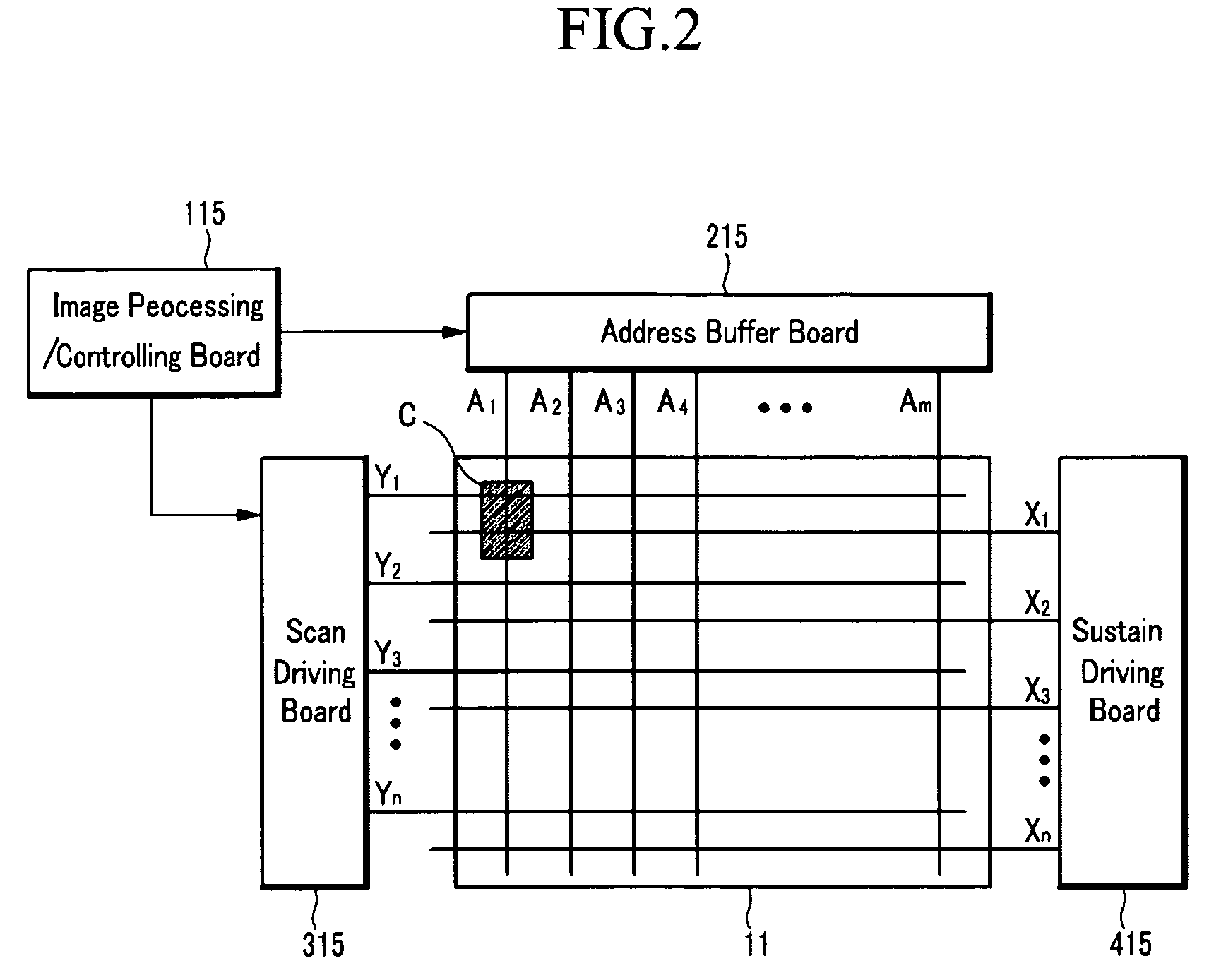

[0027] Referring to FIG. 1, a plasma display device according to the first exemplary embodiment of the present invention includes a PDP 11, a chassis base 17, and printed circuit board assemblies (PBAs) 15. The PDP 11 displays an image using a gas discharge. The chassis base 17 is attached to the rear side of the PDP 11. The PBAs 15 are mounted on the rear side of the chassis base 17, and are electrically connected to the PDP 11.

[0028] A heat dissipation sheet 13 and a double-sided adhesive tape (not shown) are interposed between the rear side of the PDP 11 and the front side of the chassis base 17. The heat dissipation sheet 13 dissipates heat generated by a gas discharge from the PDP in planar directions (x-y direction in FIG. 1).

[0029] The heat dissipation sheet 13 may be made of a heat dissipation material having sufficient thermal conductivity such as acryl, graphite, metal, or carbon nanotubes.

[0030] Since the double-sided adhesive tape attaches the PDP 11 to the chassis ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com