Reactive stimulation of oil and gas wells

a technology active stimulation, which is applied in the direction of fluid removal, drilling machines and methods, borehole/well accessories, etc., can solve the problems of reducing the efficiency of oil and gas wells, affecting the flow of fluid around the perforation area, so as to enhance the burning of hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

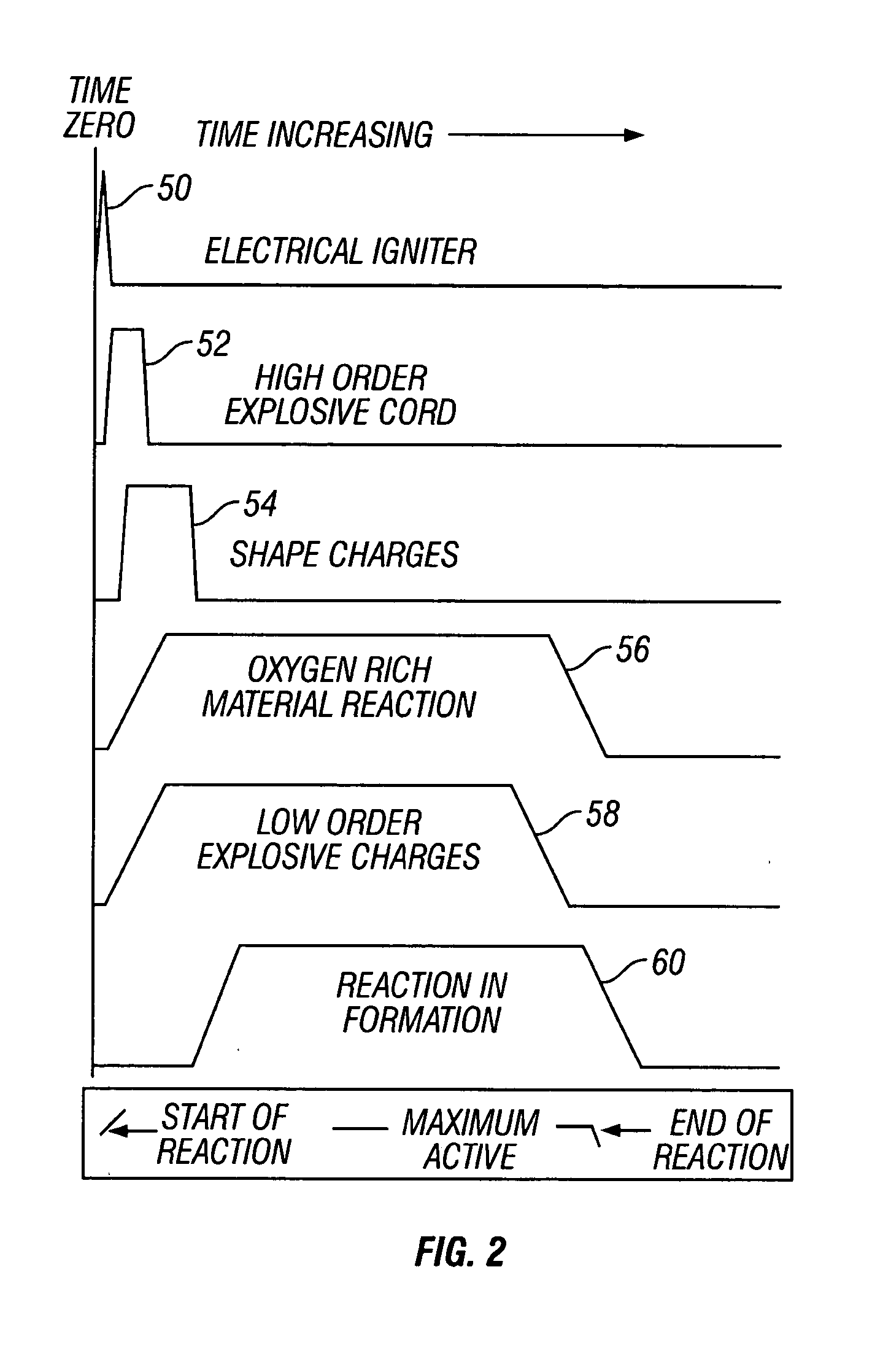

The Embodiment of FIGS. 1-3

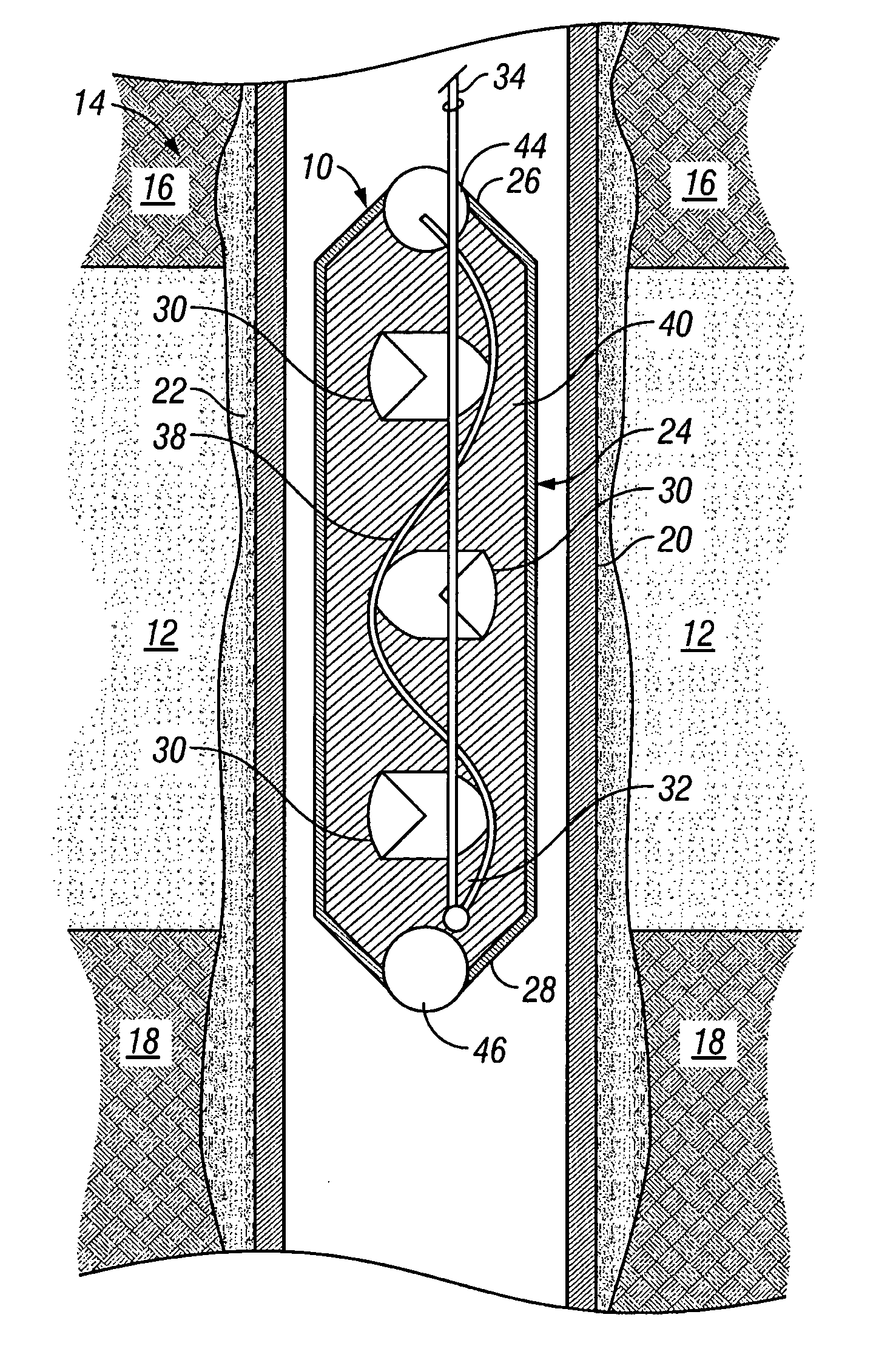

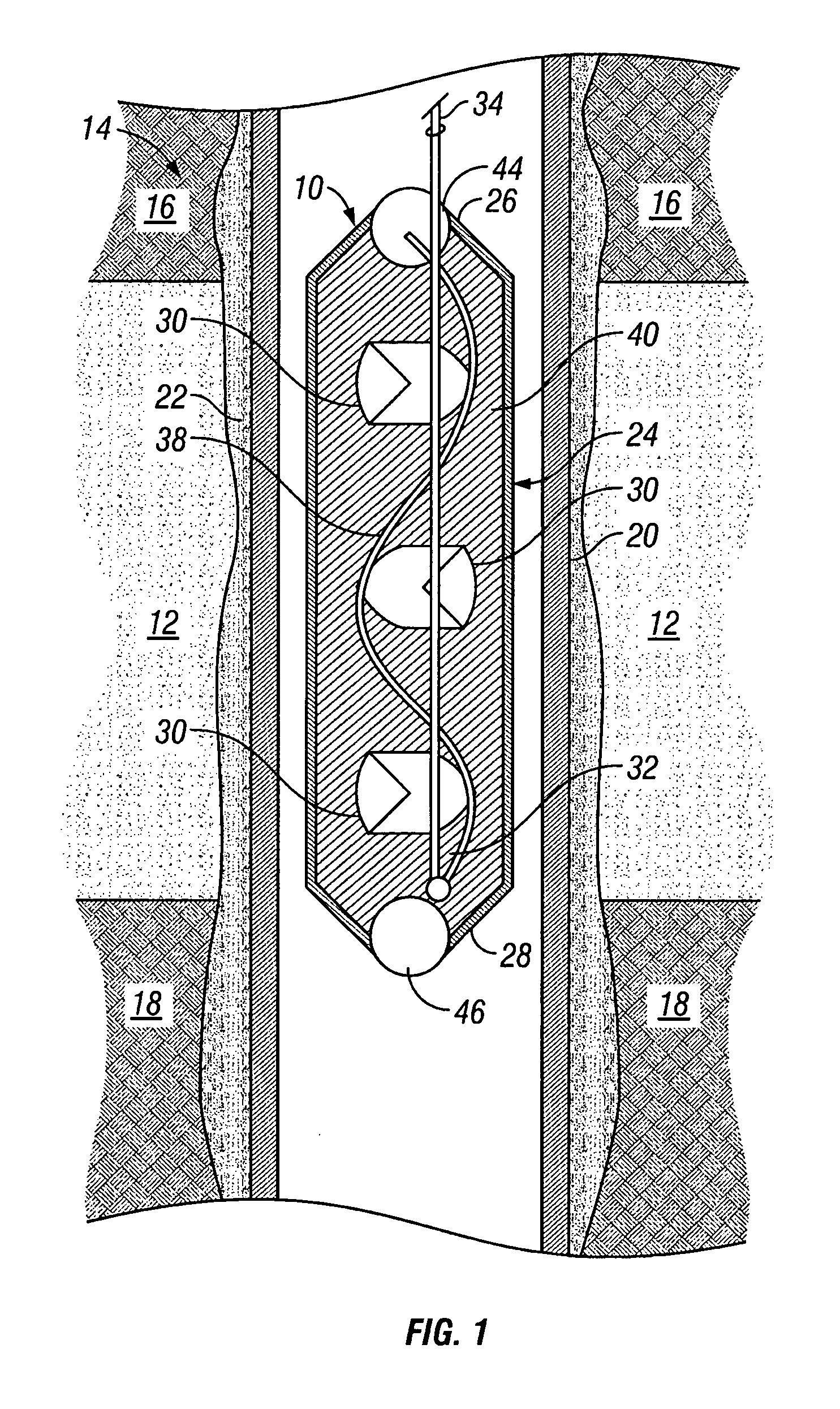

[0021] With reference now to the drawings in general and to FIG. 1 in particularly, there is shown therein an apparatus constructed in accordance with a first preferred embodiment of the present invention and designated generally by the reference numeral 10. The apparatus 10 is adapted to stimulate production from a hydrocarbon-containing formation or strata 12 in an oil or gas well 14.

[0022] An illustrative well environment is shown in FIG. 1 and comprises shale zones 16 and 18 above and below the formation 12. In most instances, the apparatus 10 will be used in a cased interval of the well 14, and the casing of the well 14 is indicated at 20 with the cement in the annulus designated at 22.

[0023] The apparatus 10 comprises a container 24 sized to be received and supported in the well 14 at a level adjacent the formation 12. Preferably, the container 24 is elongated having first and second ends 26 and 28.

[0024] The apparatus 10 further comprises at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com