Method of accurately positioning anchor bolt to foundation by swing-type anchor bolt

a technology of swing-type anchor bolts and anchor bolts, which is applied in the direction of construction, foundation engineering, etc., can solve the problems of inefficient work, inconvenient and low flexibility on the building site, and achieves a high degree of accuracy and simple procedure. , the effect of easy adjustment of the height of the anchor bolt to be positioned and installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

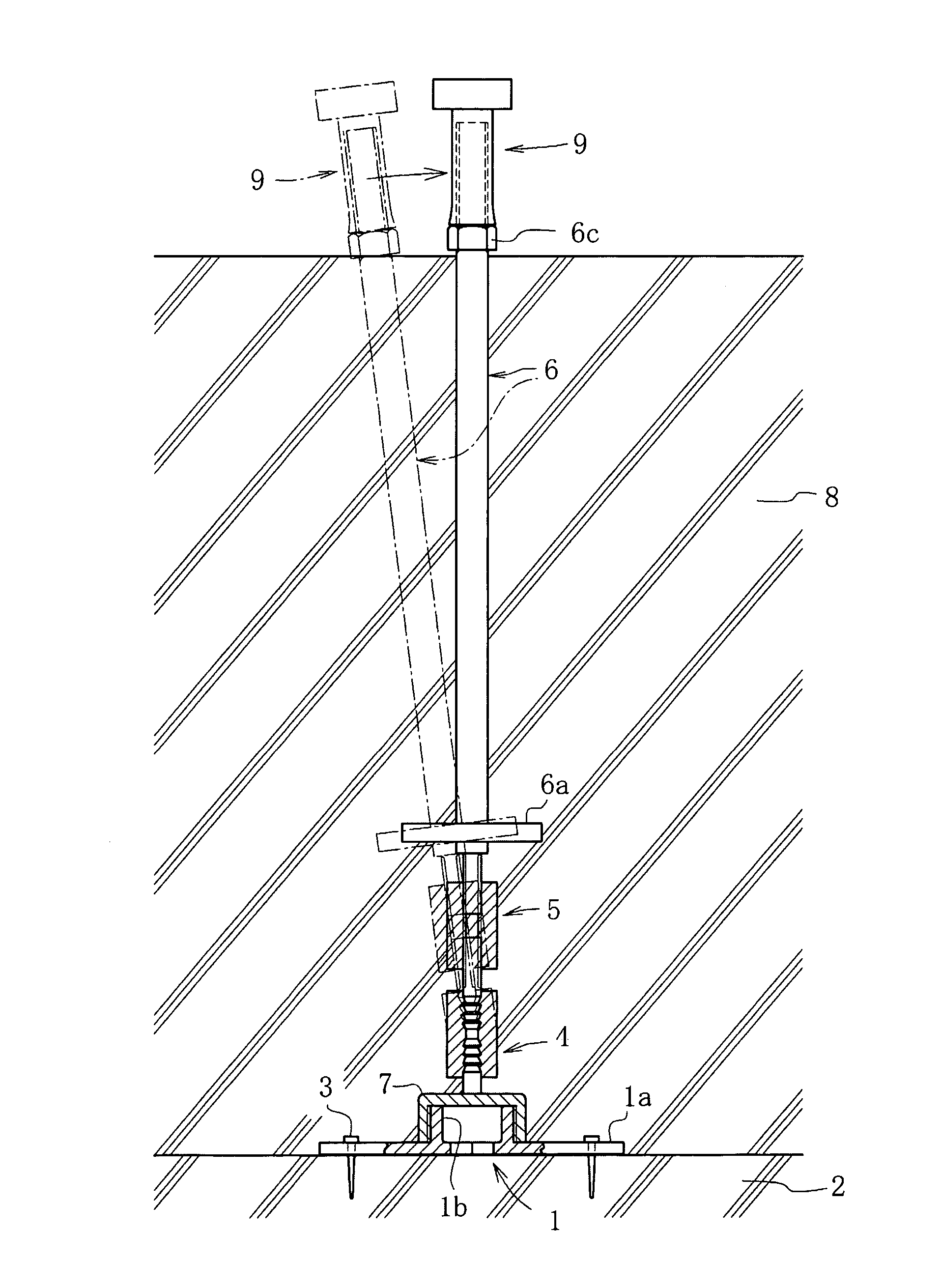

[0220] Example 1 relates to a method of positioning an anchor bolt to be installed in a concrete foundation of a wooden building and, in particular is suitable for the case of installing an anchor bolt which is required to have a high accuracy such as a hold-down anchor bolt, an anchor bolt to be installed at a portion close to a bracing, or an anchor bolt to be installed at a bed-sill joint portion. In addition, it is also suitable as a method used for positioning of all other types of anchor bolts, as a matter of course.

[0221] In a first step, a center mark for the anchor bolt to be installed is positioned and indicated on leveling concrete using this method. The leveling concrete is to be disposed within a required range in an area to establish the foundation in advance.

[0222] The center mark for the anchor bolt as described above is to be positioned directly from a reference center of a building which is separately set and indicated on the leveling concrete, and indicated with...

example 2

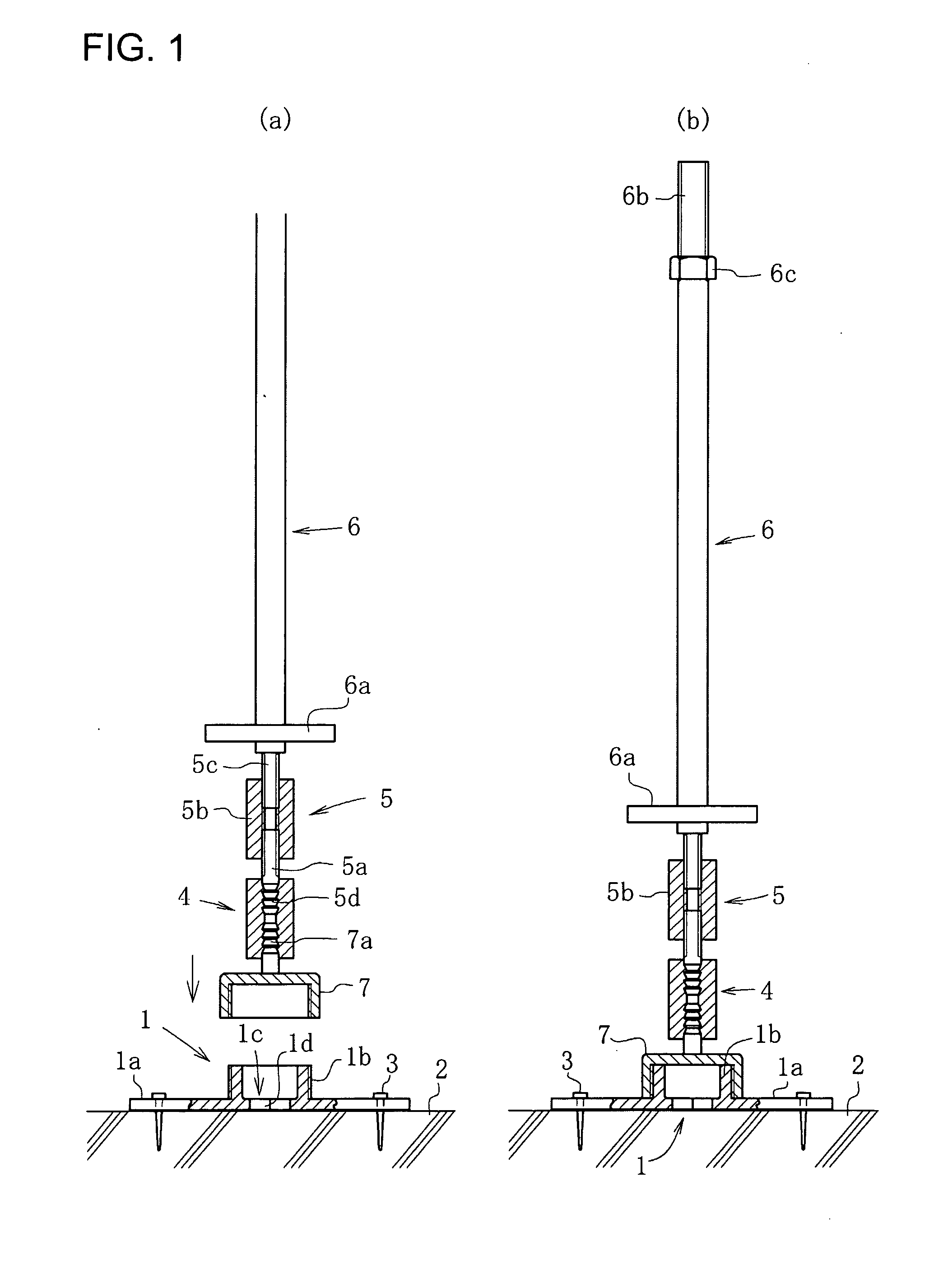

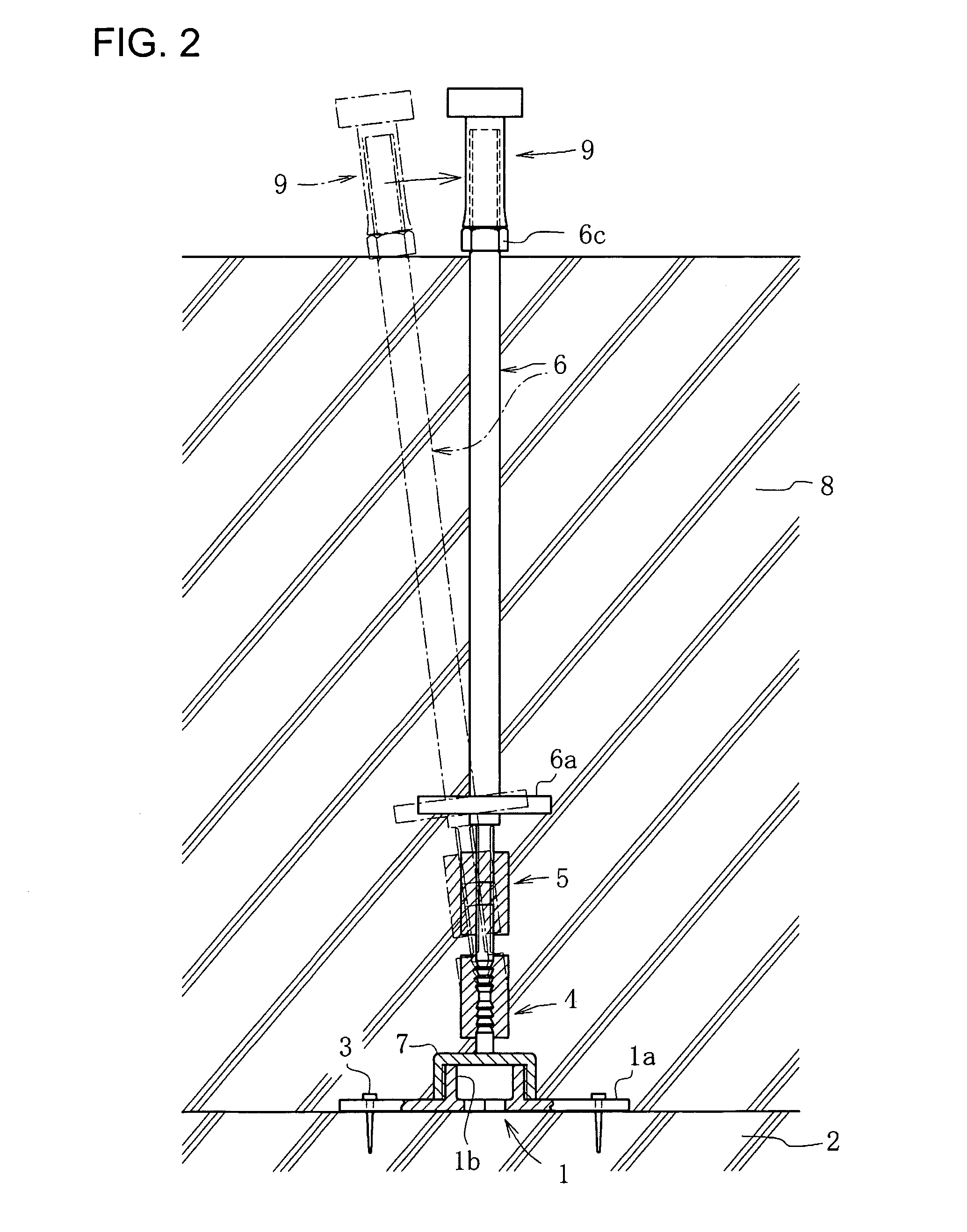

[0243] Example 2 relates to the method of positioning the anchor bolt 6 in the case in which the foundation is constructed by casting concrete for the base portion and the rising portion in two steps.

[0244] The procedure until the center marks ca, ca . . . , cs, cs . . . are positioned and indicated on the leveling concrete 2 is exactly the same as Example 1.

[0245] In Example 2 as well, the mounting member 1 having the hollow bolt 1b with the base seat 1a which is the same as Example 1 is installed so as to match the corresponding center mark ca. The method of positioning the mounting member 1 in this case is the same as those described in Example 1. However, in Example 2, the more accurate verticality of the hollow bolt 1b which extends upright from the mounting member 1 is required. In this case, the base seat 1a is positioned, and is temporarily fixed as shown in FIG. 6(a), and then the ball head lock nut 7 with an extension shaft 7b extending upright from an upper surface ther...

example 3

[0254] Example 3 relates to a method of positioning the anchor bolt 6 in the case in which the foundation is constructed in two steps by casting concrete for the base portion and the rising portion as in the case of Example 2, and is different from Example 2 in the process after positioning and indication of the center marks ca, ca . . . and cs, cs . . . on the leveling concrete 2 until upright disposition and fixation of the extension shaft 7b. Since the different point is only the process described above, only the different point will be described.

[0255] As shown in FIG. 10(a), a drill d is aligned with the corresponding center mark ca on the leveling concrete 2 and a mounting hole hm is drilled. Then, as shown in FIG. 10(b), a plug member p is press fitted and fixed in the mounting hole hm. Subsequently, as shown in FIG. 10(c), a screw member 1e is provided as the anchor bolt mounting means at the lower end of the extension shaft 7b, and the extension shaft 7b provided with a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com