Dual-Layer Medical Balloon

a balloon and dilatation technology, applied in the field of balloons, can solve the problems of limiting the applicability of balloons as bio-compatible materials, exhibiting less flexibility and trackability than desired, and high burst strength of balloons made from high-strength polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

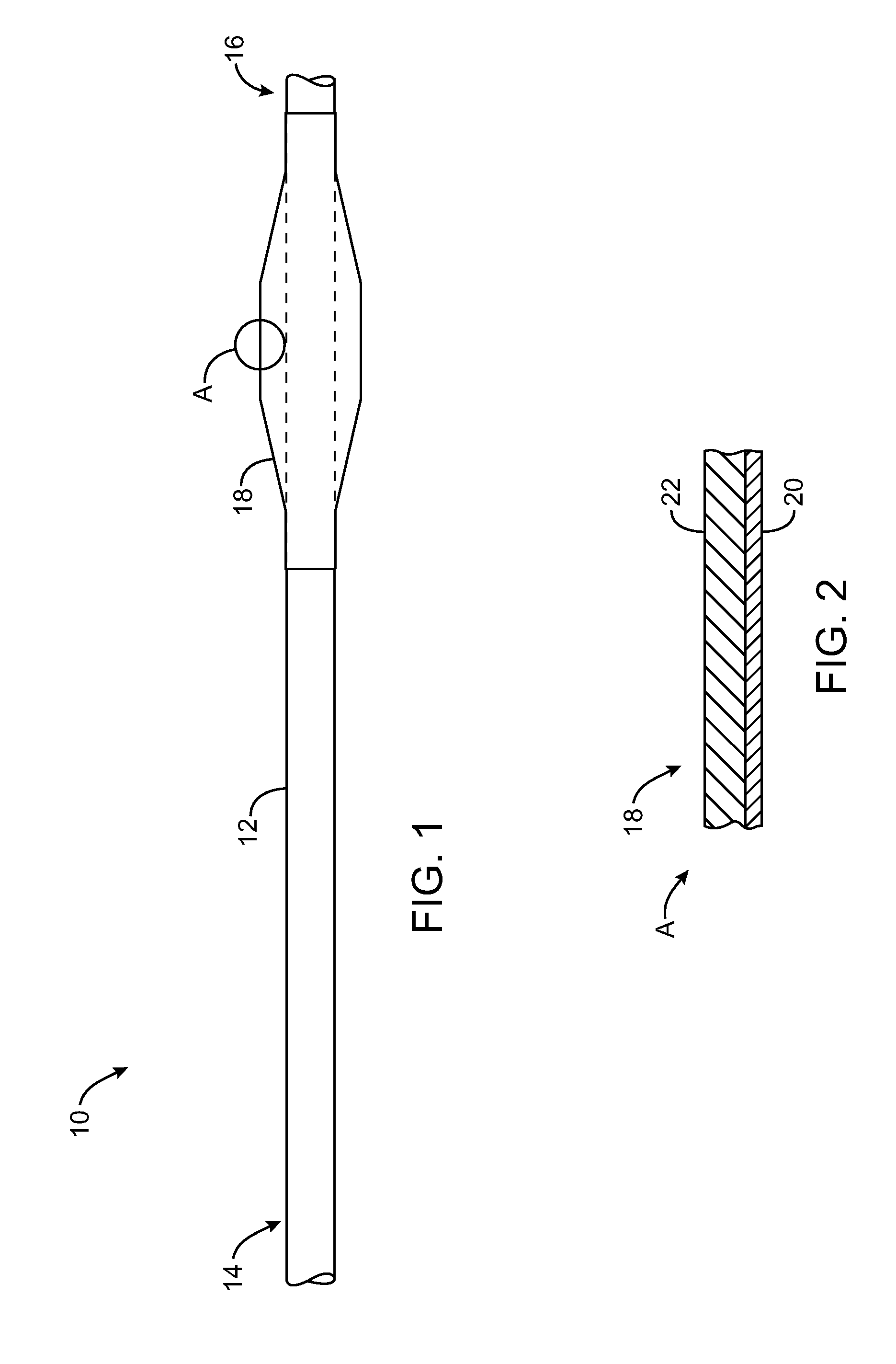

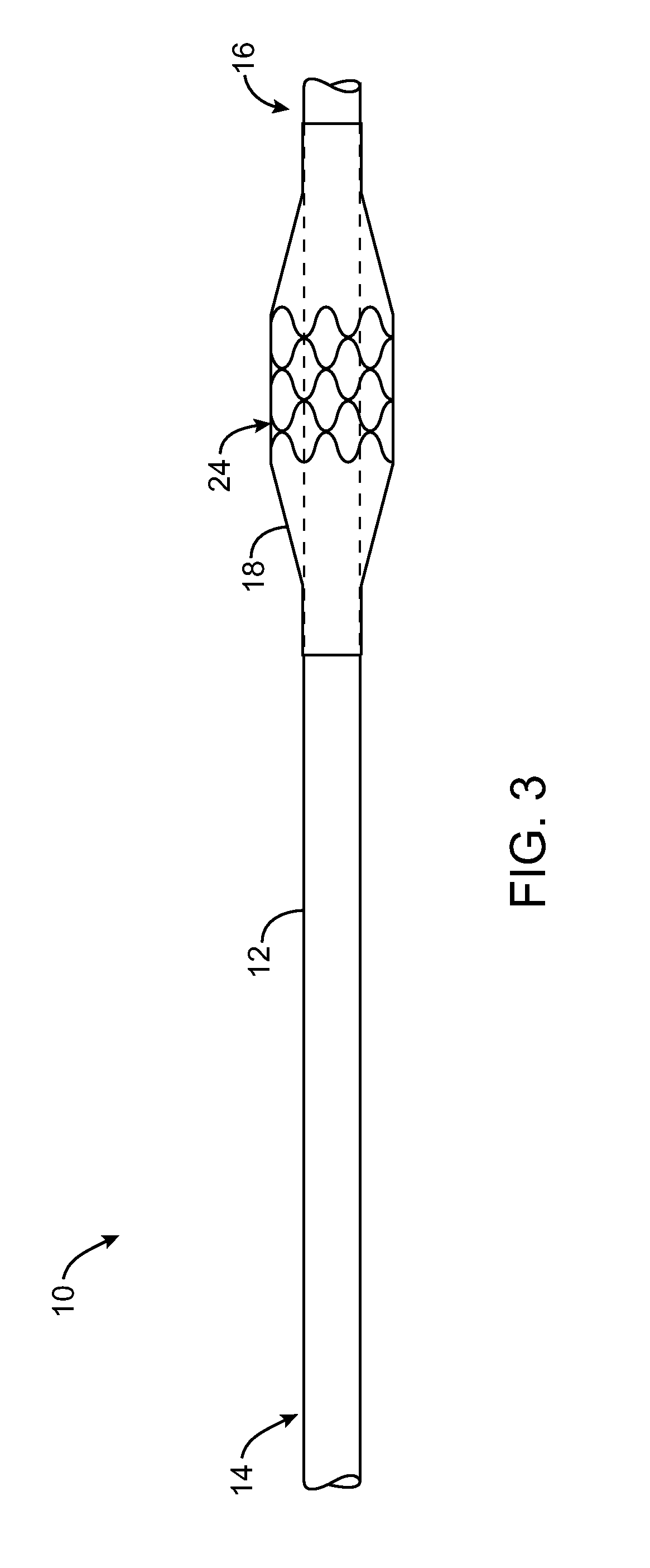

[0020] It is desirable to improve the flexibility and trackability of dilatation balloons while maintaining a high degree of strength in the balloon. Preferably, these improvements are made while limiting the use of plasticizers, which can migrate out of the balloon. Improved flexibility and trackability would allow a surgeon to maneuver the balloon, and alternatively, a balloon and stent, through very small diameter vasculature that may have a large degree of blockage or plaque build-up. The high degree of strength provides the surgeon with maximum flexibility to inflate the balloon, and alternatively to deliver a stent upon inflation, without bursting the balloon. In order to improve the flexibility of standard balloons without the use of plasticizers, or alternatively, with the limited use of plasticizers, a softer and more flexible material is co-extruded with a high-strength material to form a dual-layer balloon.

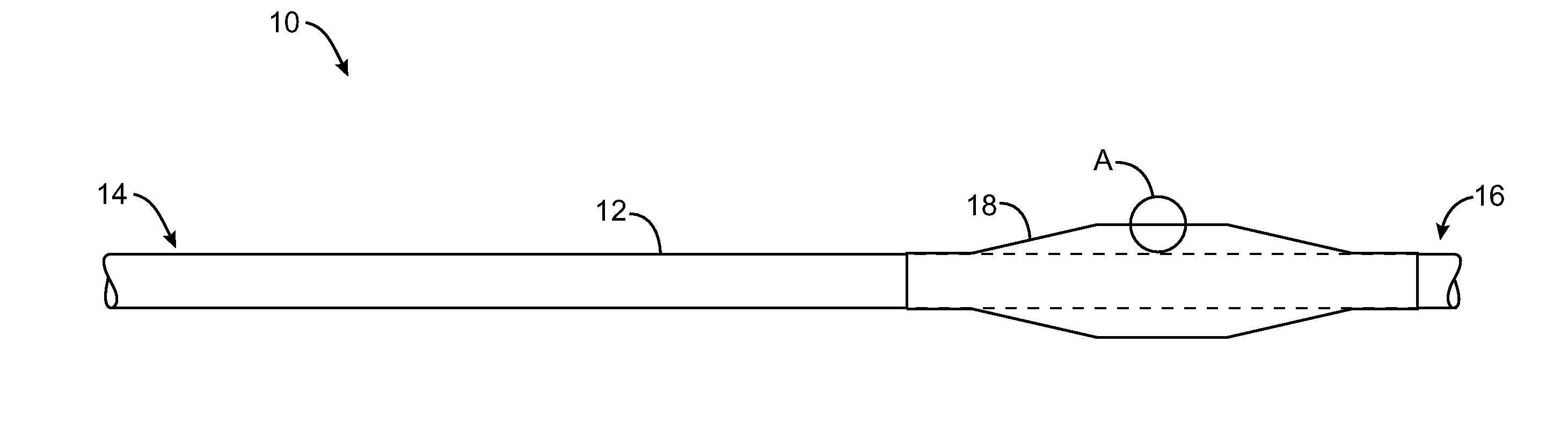

[0021] A balloon dilatation catheter 10 according to an embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com