Lens barrel

a barrel and lens technology, applied in the field of lenses barrels, can solve the problems of poor operation, unintentional touching and moving, and wrong operation of instruction-type focus rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The best mode for carrying out the lens barrel according to the present invention will be described below based on the attached drawings.

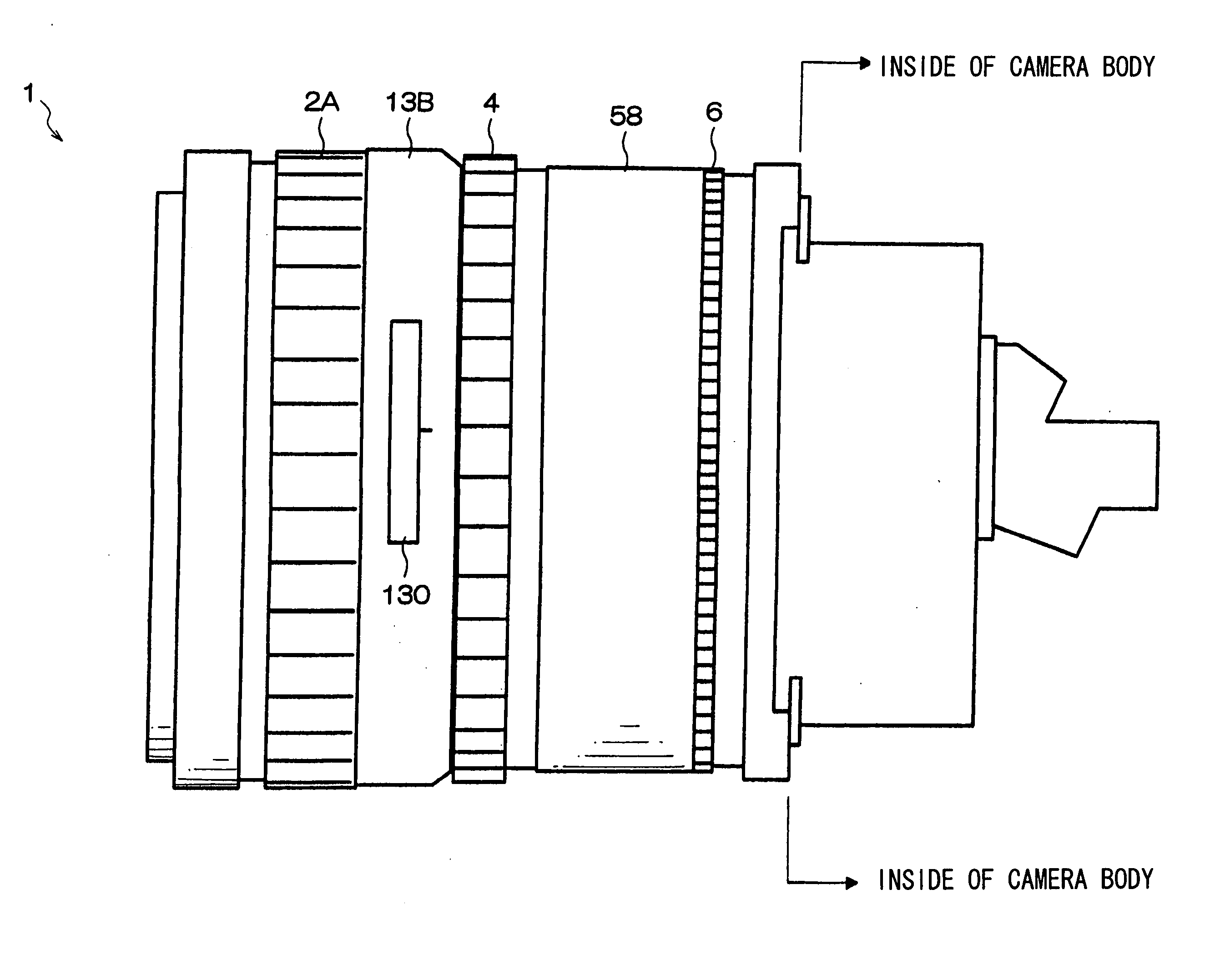

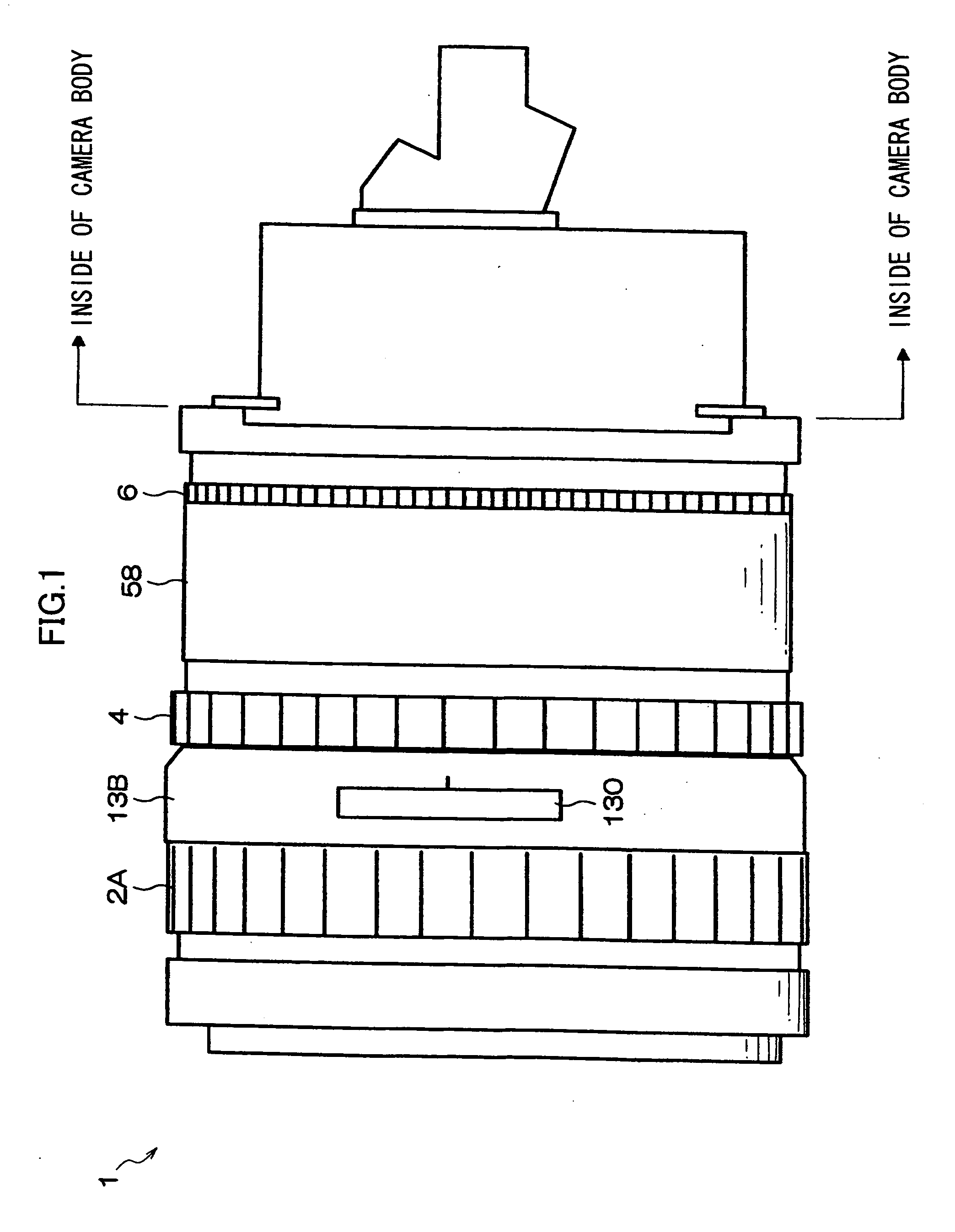

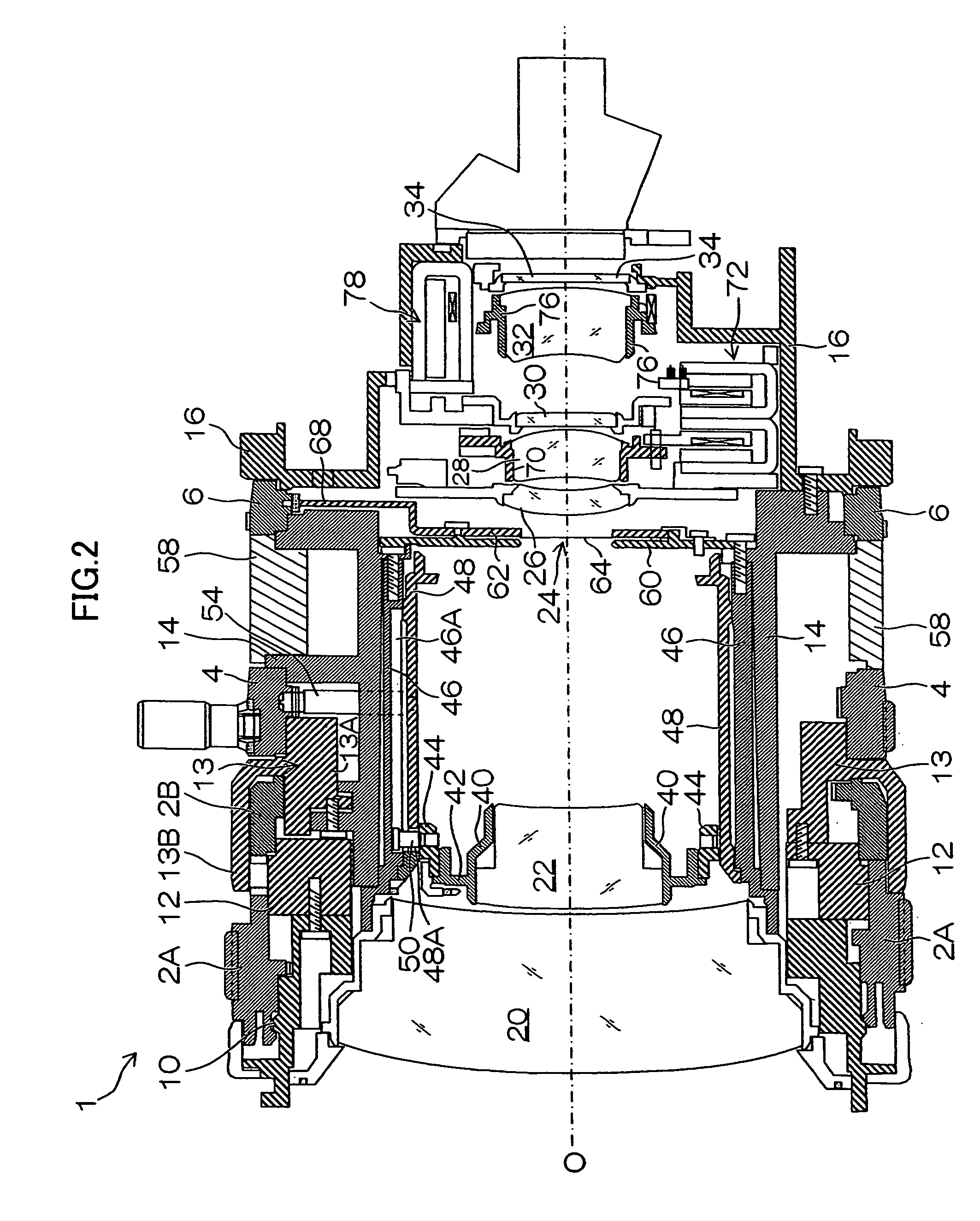

[0030]FIGS. 1 and 2 show a side view and a side sectional view, respectively, showing a lens barrel in a rear-focus type variable focal distance photographing lens applied to a video camera for consumers, an ENG camera for TV broadcasting, a monitoring camera and the like, for example, to which the present invention is applied. In these figures, a lens barrel used mainly in the video camera for consumers is shown, and an optical block such as color separation prism attached on a camera body with interchangeable lenses is integrally mounted at a rear end of a lens barrel 1.

[0031] In FIG. 1, the lens barrel 1 is constructed in the substantially cylindrical shape and it is fixed to an enclosure of a camera body in the state where a part of the rear end side is inserted into the enclosure of the camera body, not shown. Rotatable operation ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com