Electrode structure

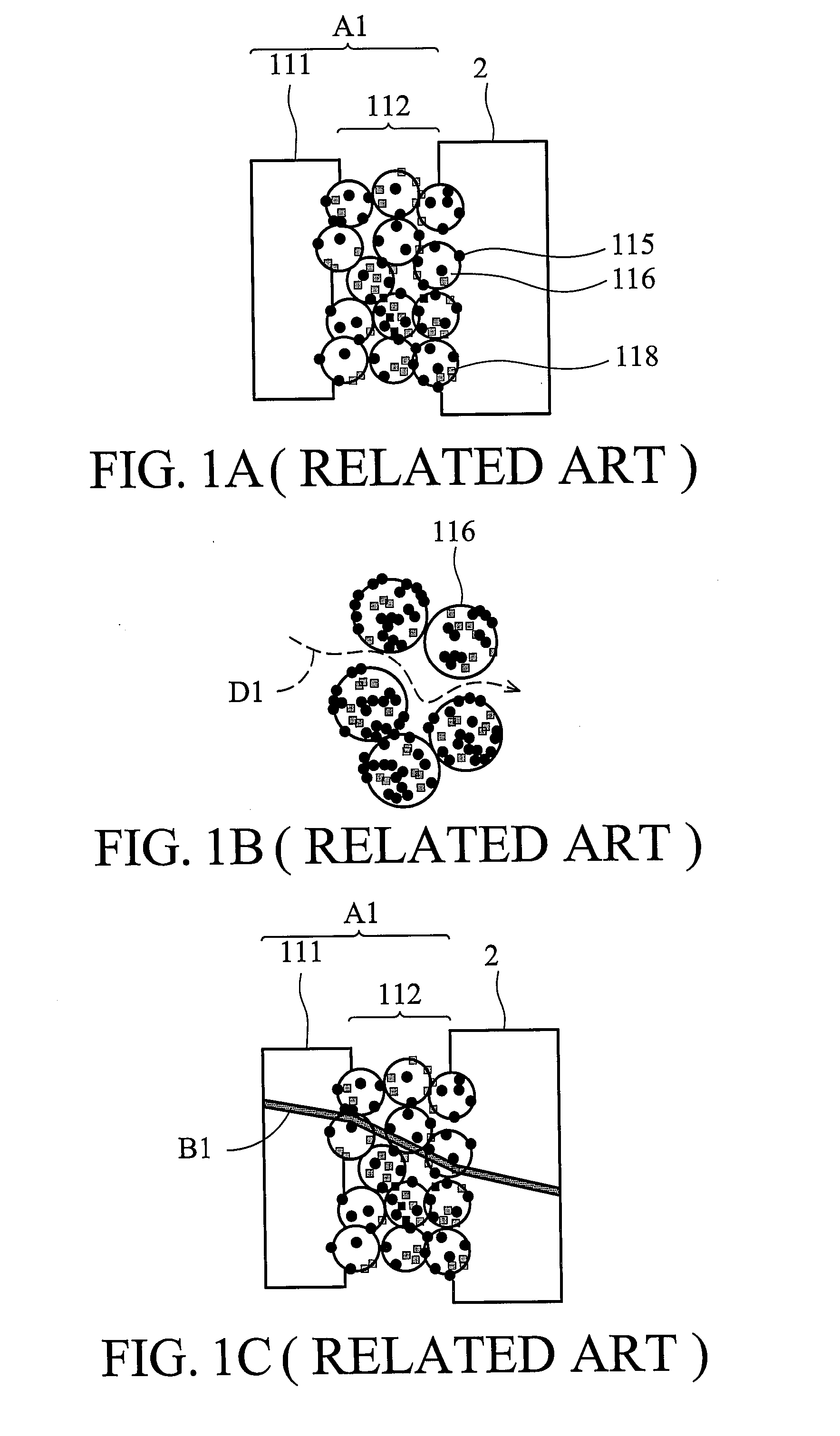

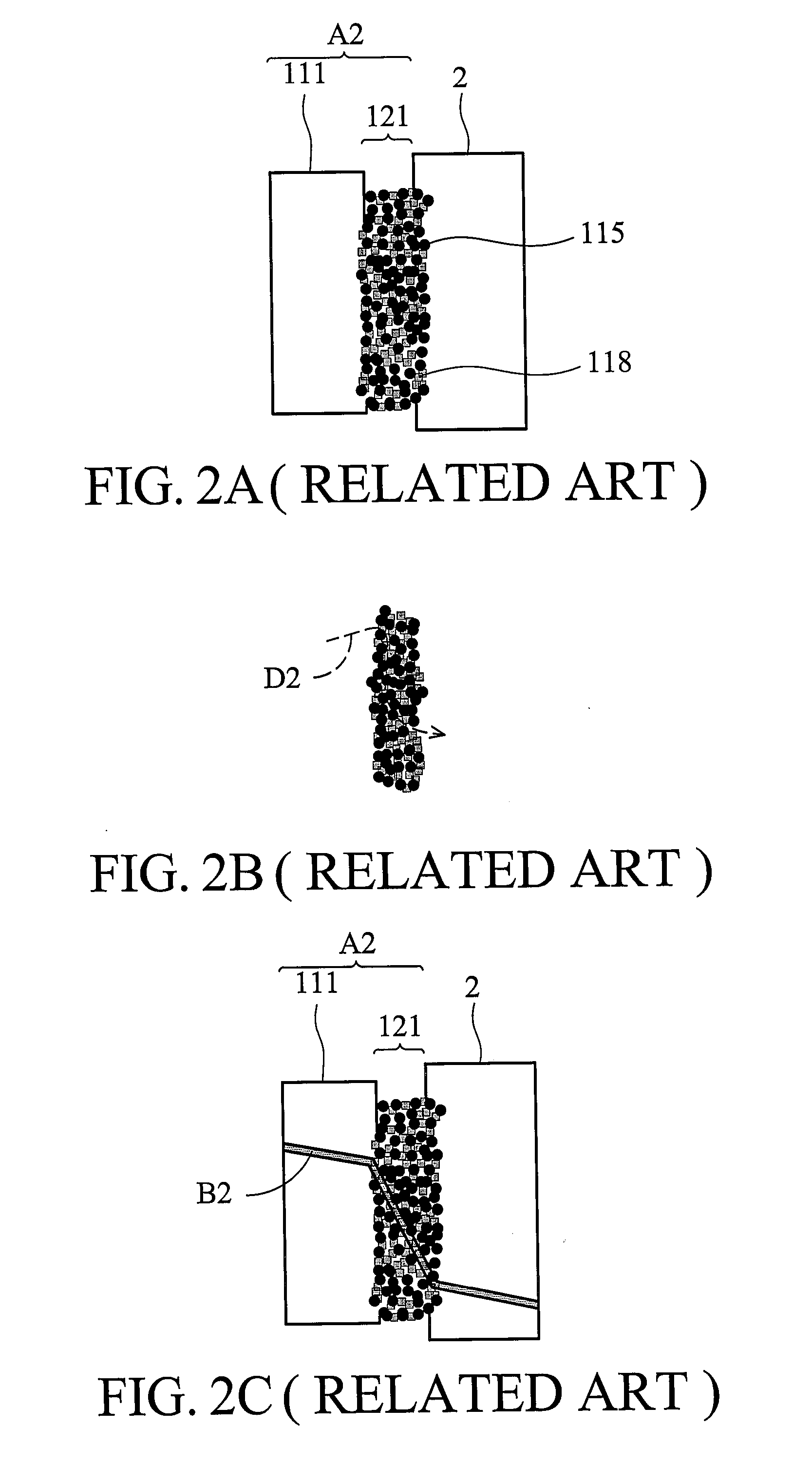

a technology of electrochemical structure and electrode, which is applied in the direction of electrochemical generators, cell components, basic electric elements, etc., can solve the problems of accelerating aging reducing the catalytic reaction performance of the cathodic structure, and unwanted crossover of fuel from the anodic structure throughout the cathodic structure, so as to reduce the total material cost of the fuel cell, increase the output voltage of the fuel cell and power density, and reduce the amount of catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description is of the best-contemplated mode of carrying out the invention. This description is made for the purpose of illustrating the general principles of the invention and should not be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

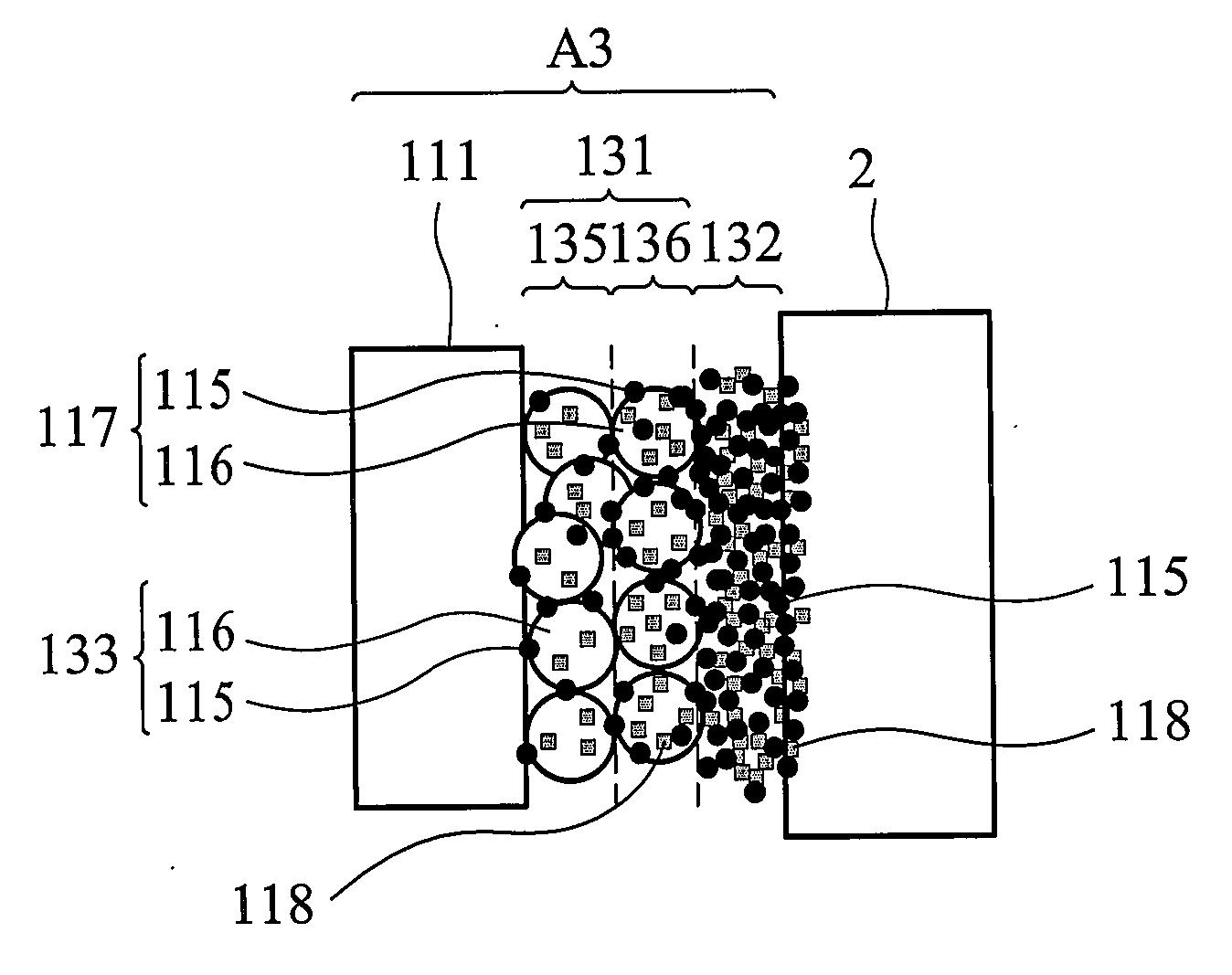

[0045] In FIG. 4, a power generation fuel cell of a first embodiment comprises a fuel (not shown in Figs.) and an electrode structure 100 used to actuate the fuel to generate electricity. The electrode structure 100 sequentially comprises a cathodic structure 72, an ionic exchange membrane 2 disposed next to the cathodic structure 72, and an anodic structure 71. The anodic structure 71 sequentially comprises a first thin platinum alloy black layer 711 disposed next to the ionic exchange membrane 2, a platinum alloy carbon support layer 712 and a first substrate layer 713. The first thin platinum alloy black layer 711 is a thin and dense catalyst layer by a plurality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| anti-corrosive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com