Bendable 'Z' head flashing

a head flashing and bendable technology, applied in the direction of snow traps, doors/windows, roofing, etc., can solve the problems of difficult installation of head flashing along curved surfaces, inability failure to meet the requirements of construction, so as to reduce the possibility of cracking and buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

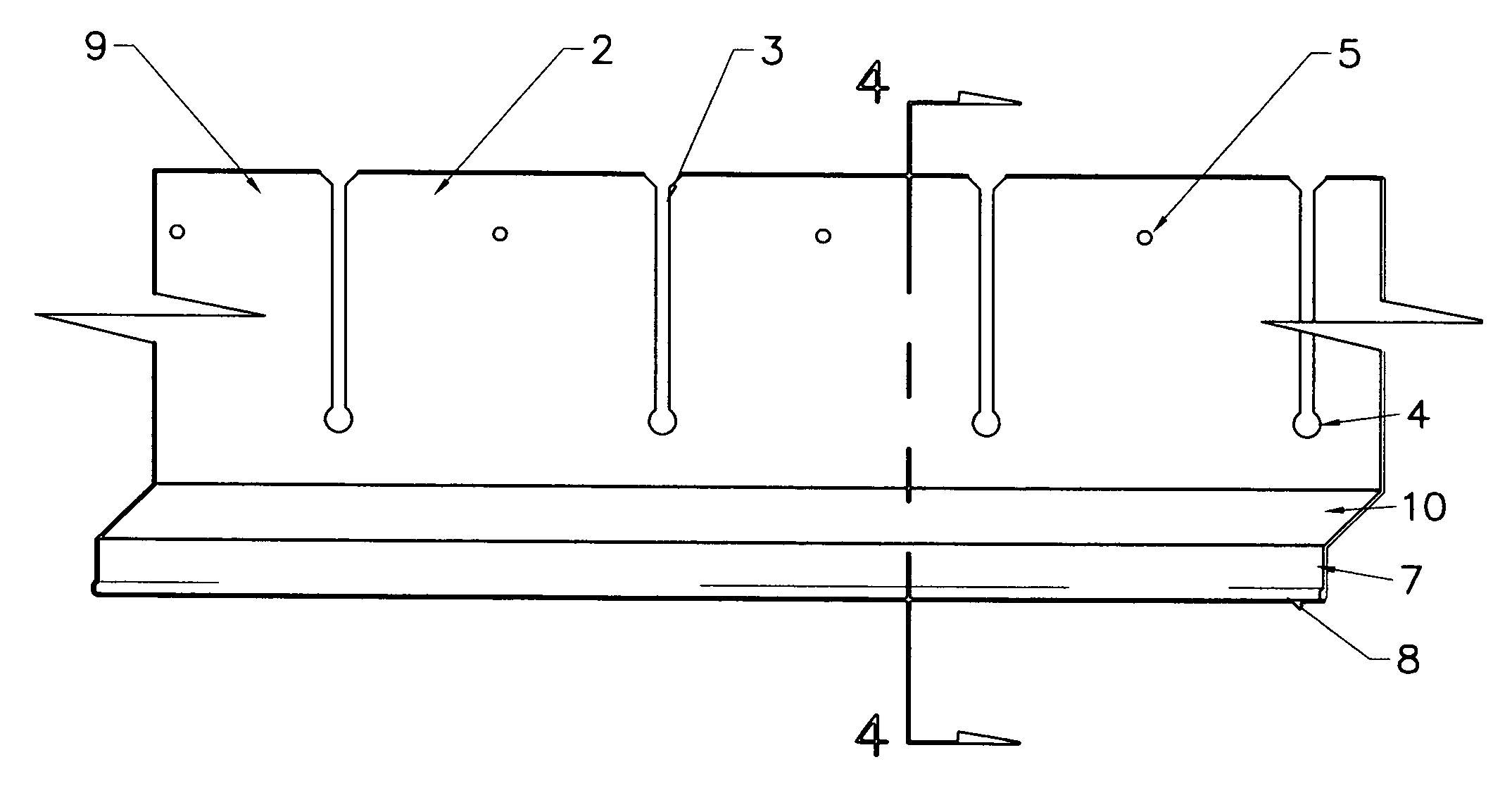

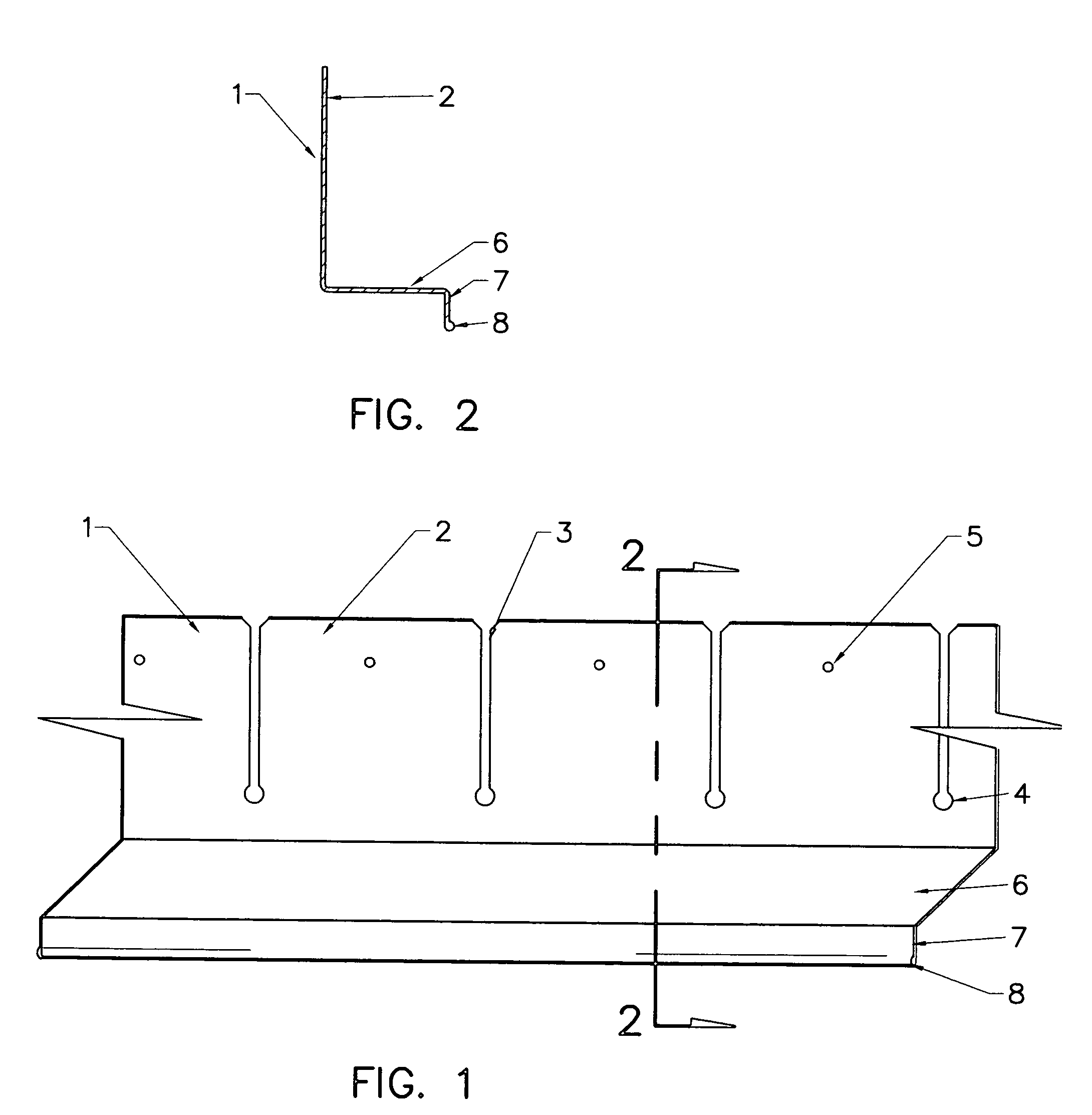

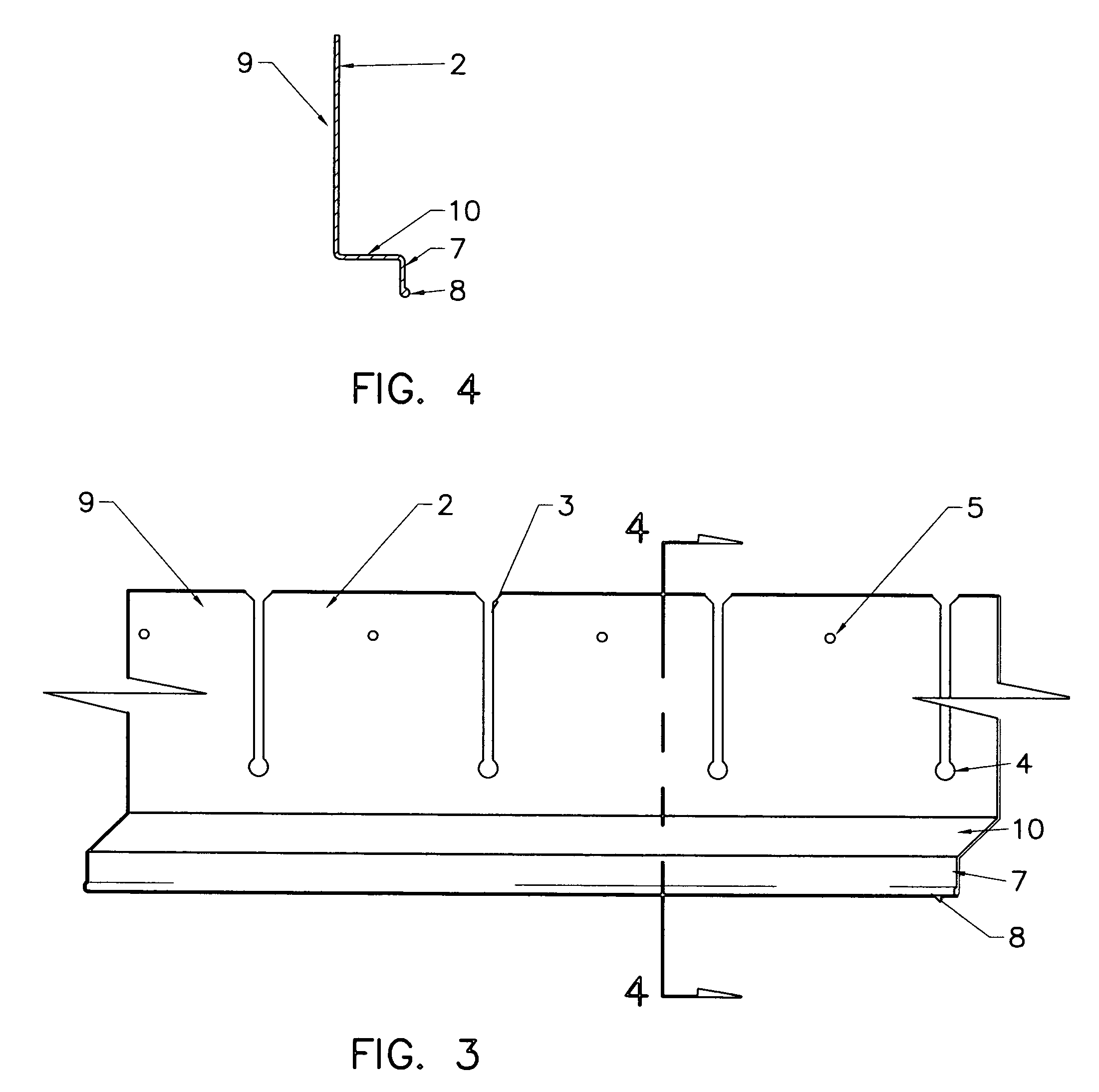

[0023]FIGS. 1-8 illustrate two embodiments of the present invention. FIGS. 1 and 2 indicate one embodiment, while FIGS. 3 and 4 show a second embodiment. FIGS. 5-8 show the bendable ‘Z’ head flashing integrated into different building components. Building components illustrated in FIGS. 5-8 characterize the use and installation of the present invention, but do not preclude use of bendable ‘Z’ head flashing with other building materials and construction components.

[0024]FIG. 1 is a oblique view of a portion of a novel bendable ‘Z’ head flashing 1. The rear vertical mounting flange 2 is shown with equally spaced notches 3. Each notch terminates in a circular void 4, being in proximity to the horizontal section, but maintaining a distance to provide a small section of uninterrupted vertical flange adjacent to the horizontal flange. When the horizontal leg 6 is curved during installation to conform to a radius, notches 3 will uniformly spread apart along the upper free edge of vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com