Vapor extracting and separator cleaning apparatus

a technology of separator and extraction chamber, which is applied in the direction of lighting and heating equipment, domestic stoves or ranges, and accessories of wellbore/wells. it can solve the problems of increased potential exposure to dangerous vapors, inability to separate the separator from the rest of the equipment, and inability to extract vapors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

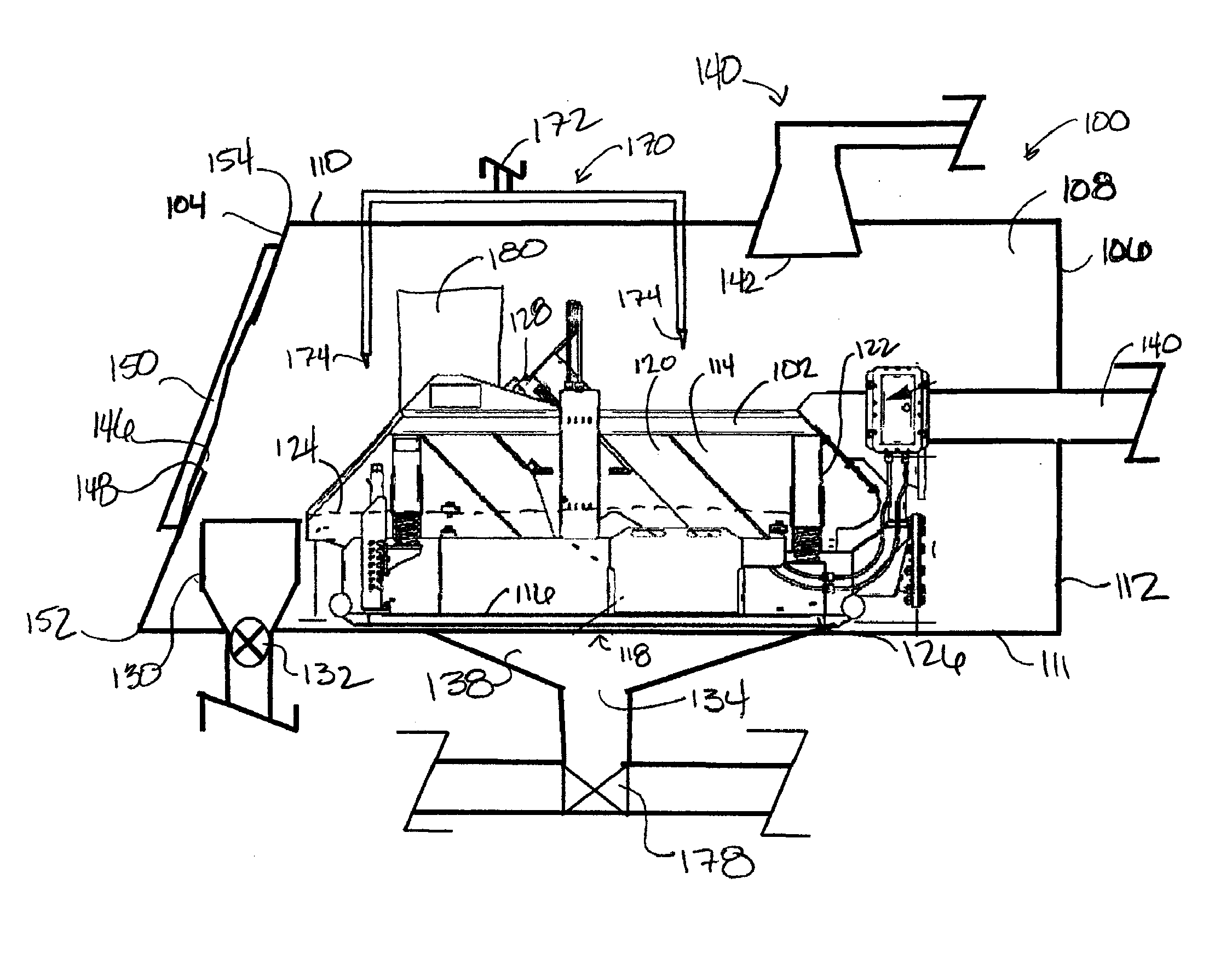

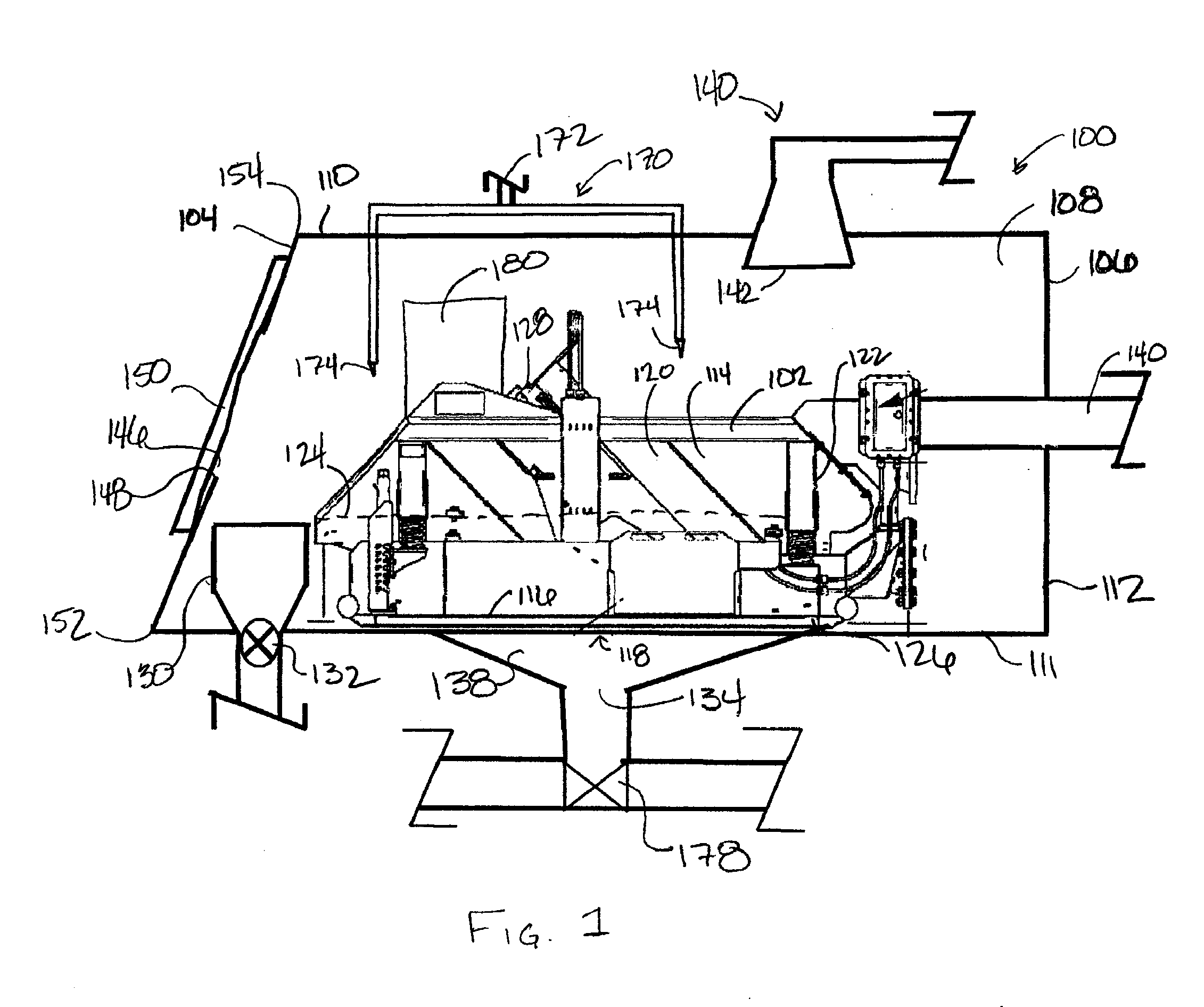

[0013] The claimed subject matter relates to an apparatus 100 for extracting vapors and cleaning shakers. Referring to FIGS. 1 and 2, the apparatus 100 has a plurality of walls 104,106, 108, shown, and a top wall 110 forming a cabinet 112 or enclosure around a separator 102. A drilling fluid feed 140 directs the unseparated drilling fluid into cabinet 112 to separator 102.

[0014] As one of skill in the art will appreciate, separator 102 may be of any model and type. A typical shaker separator 102 includes a basket 114 that includes a bottom wall 116 having an opening 118, a pair of side walls, 120 (one wall shown), and an end wall 122. End wall 122 is located at the feed end of the separator 102. At least one screening surface 124 is located in the basket 114. The screening surface 124 has a plurality of apertures through which fluid may pass. The opening 118 in the bottom wall 116 is beneath the screening surface 124 to direct filtered fluid out of separator 102 for further process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com