Pouring apparatus for carbonated beverages in bottles

a technology for pouring apparatus and carbonated beverages, which is applied in the direction of liquid handling, closure using stoppers, caps, etc., can solve the problems of low cost, situation can occur, and special “bubbly” character of beverages, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The principle behind the invention described here is simple. An apparatus is placed inside the neck of a bottle which contains a carbonated beverage. This apparatus allows the beverage to be dispensed as desired, while retaining most of the pressurized gas inside the bottle. This allows the beverage to retain its “fizz” from the time the first sip is consumed until the last sip is consumed.

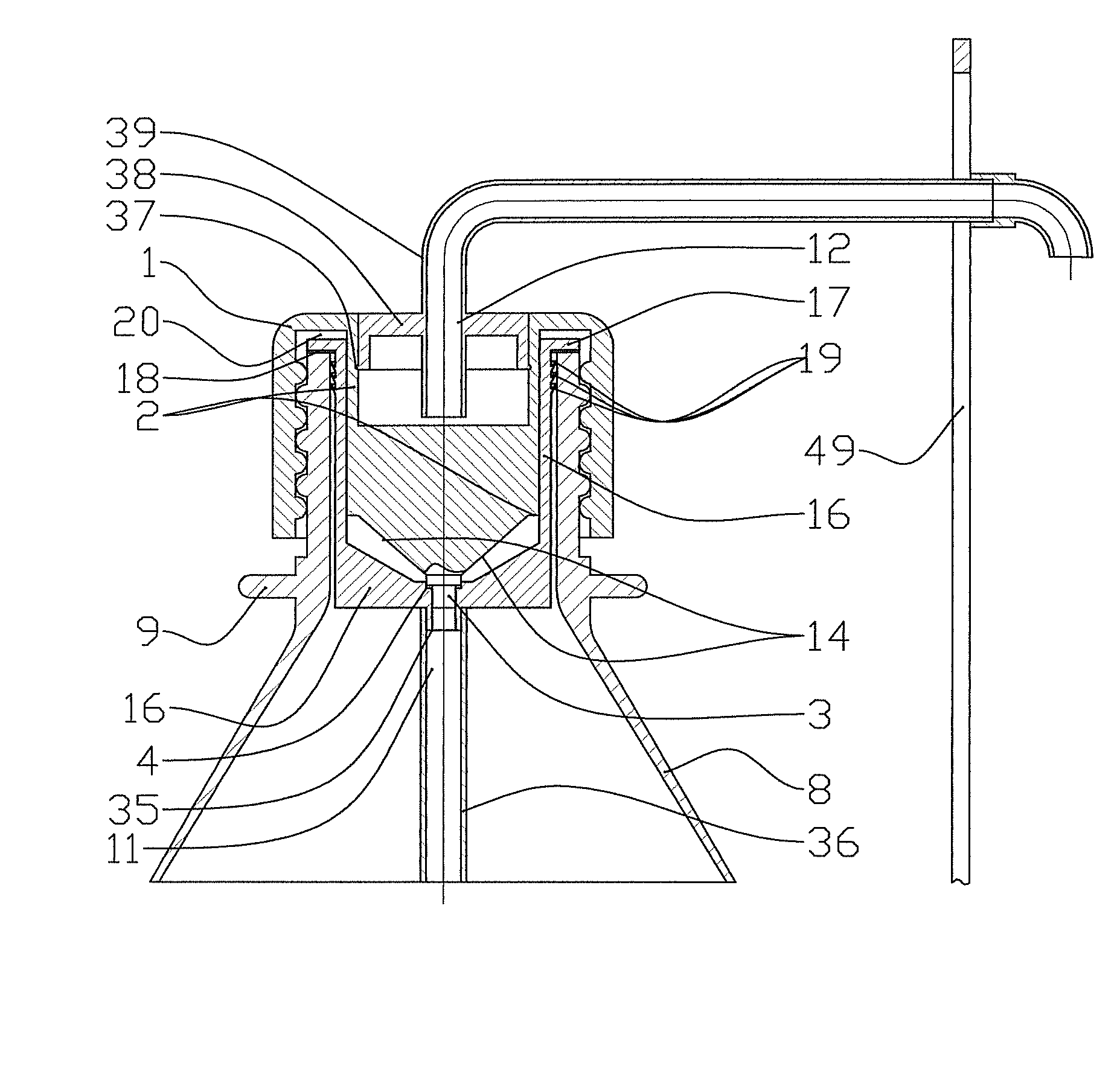

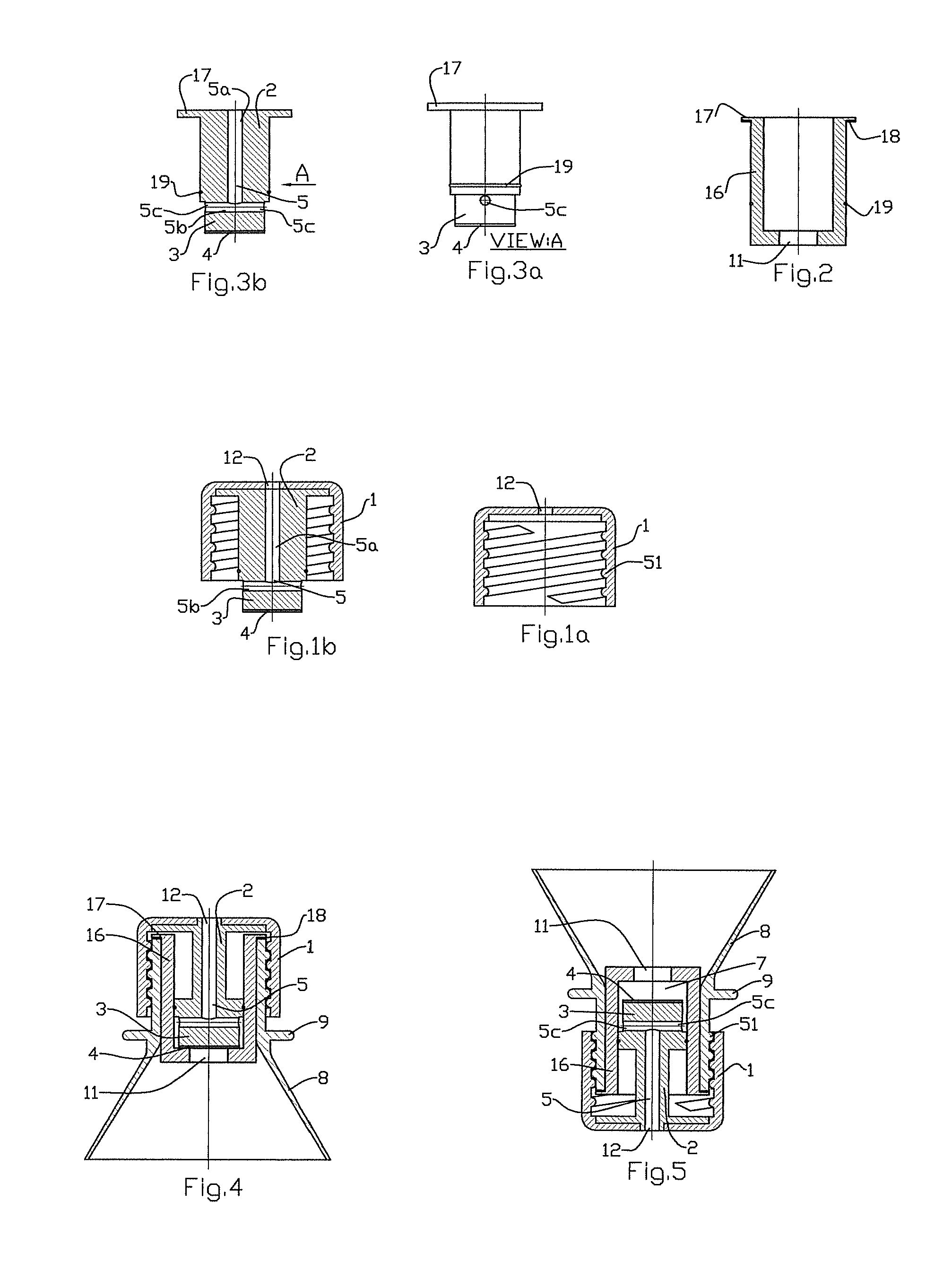

[0078] The apparatus is cylindrical in shape, and comprises a cylinder and a piston. In the practice of the invention, the piston is attached to a cap, which is fitted onto the bottle by means known in the conventional art. FIG. 4 shows a partial cutaway view of the invention in use, while the bottle is closed, holding the beverage inside. Cap 1 sits on top of Bottle 8 in the usual manner, the inside threads of Cap 1 engaging the outside threads on Bottle 8. The visible difference between the present invention and a conventional soda bottle is Opening 12, located at the top of Cap 1. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com