Cleaning system

a fan and cleaning system technology, applied in the direction of piston pumps, pump components, non-positive displacement fluid engines, etc., can solve the problems of fan major downtime and maintenance, and achieve the effect of eliminating down time and inefficiency, high velocity, and more adjustment of crank rod length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

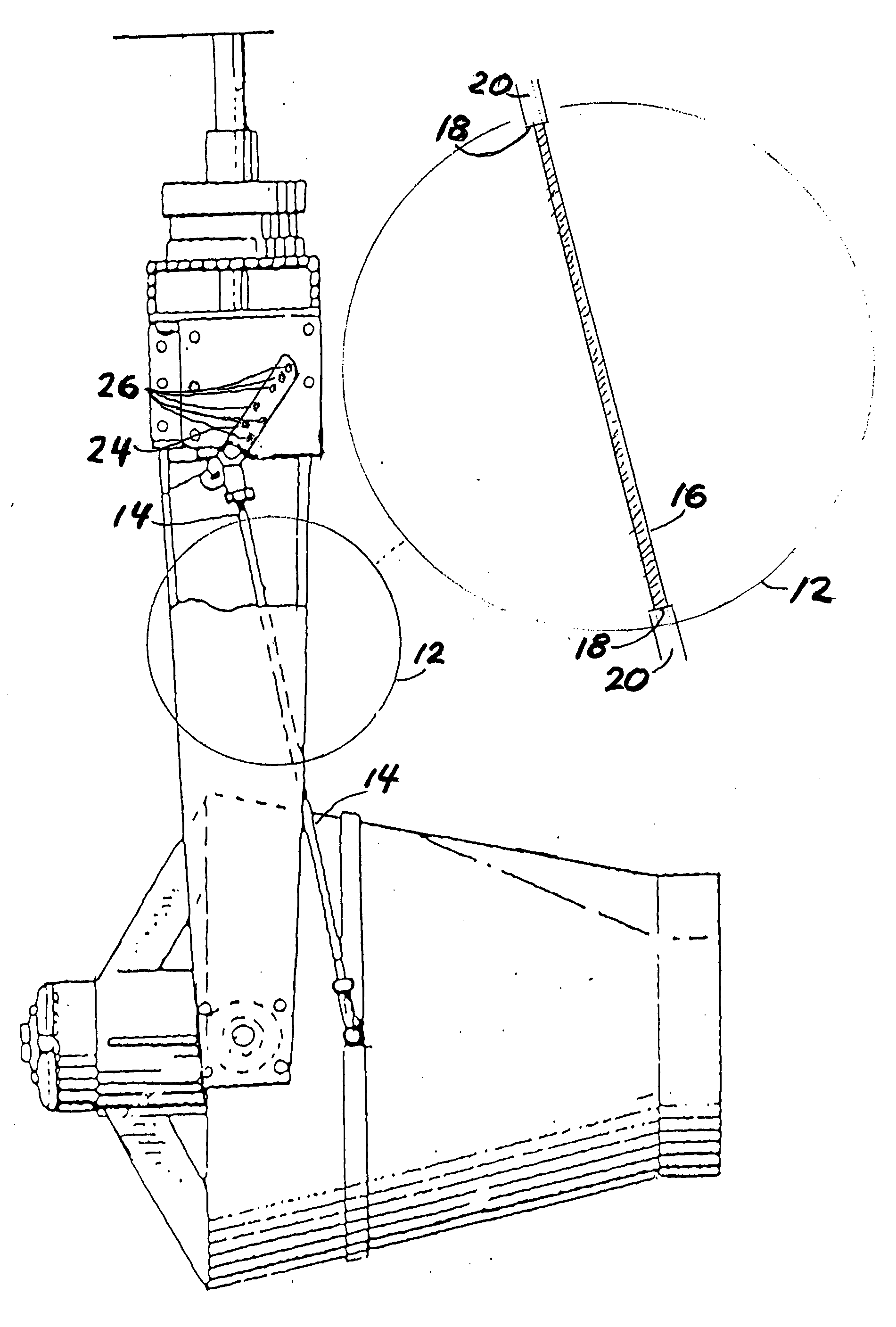

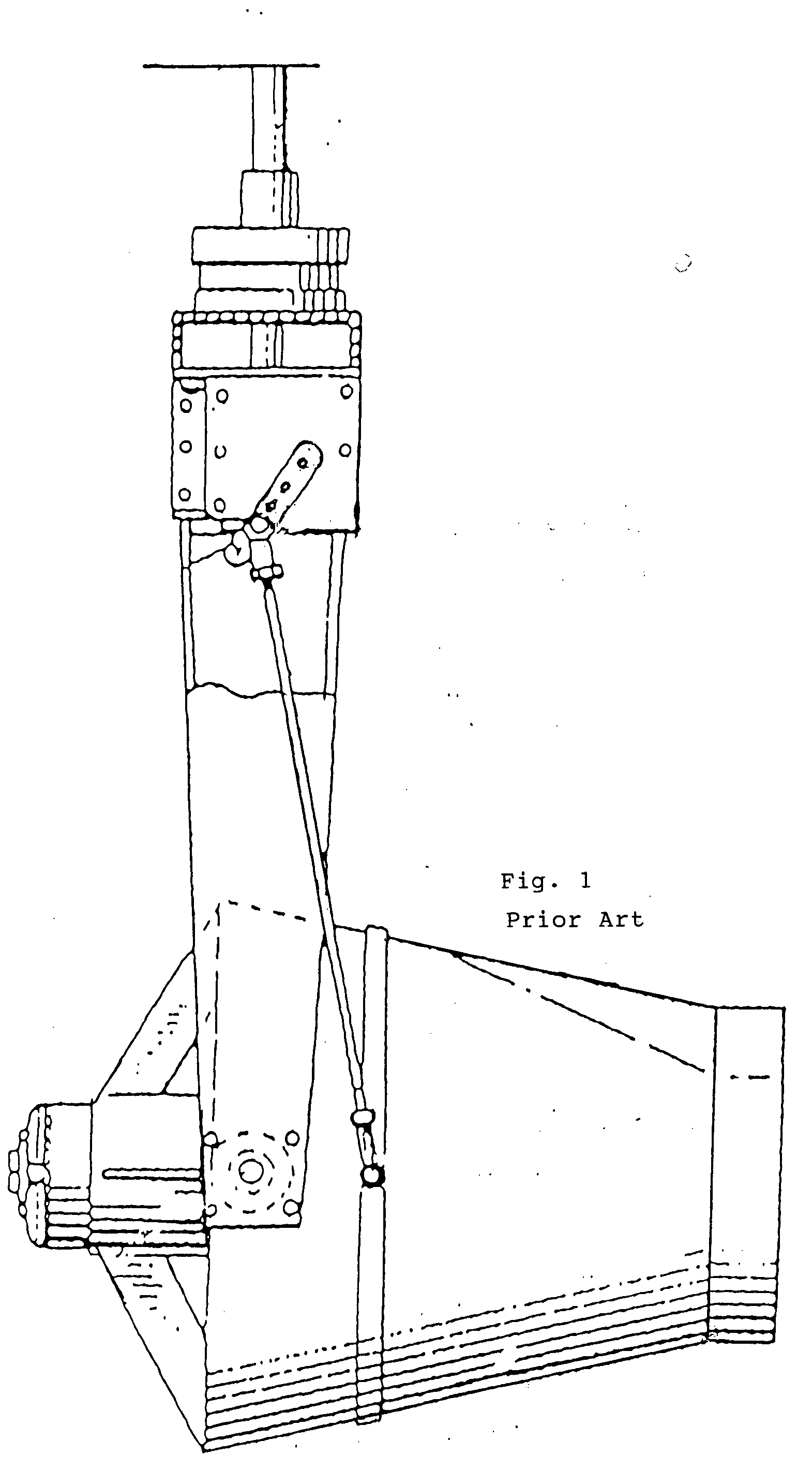

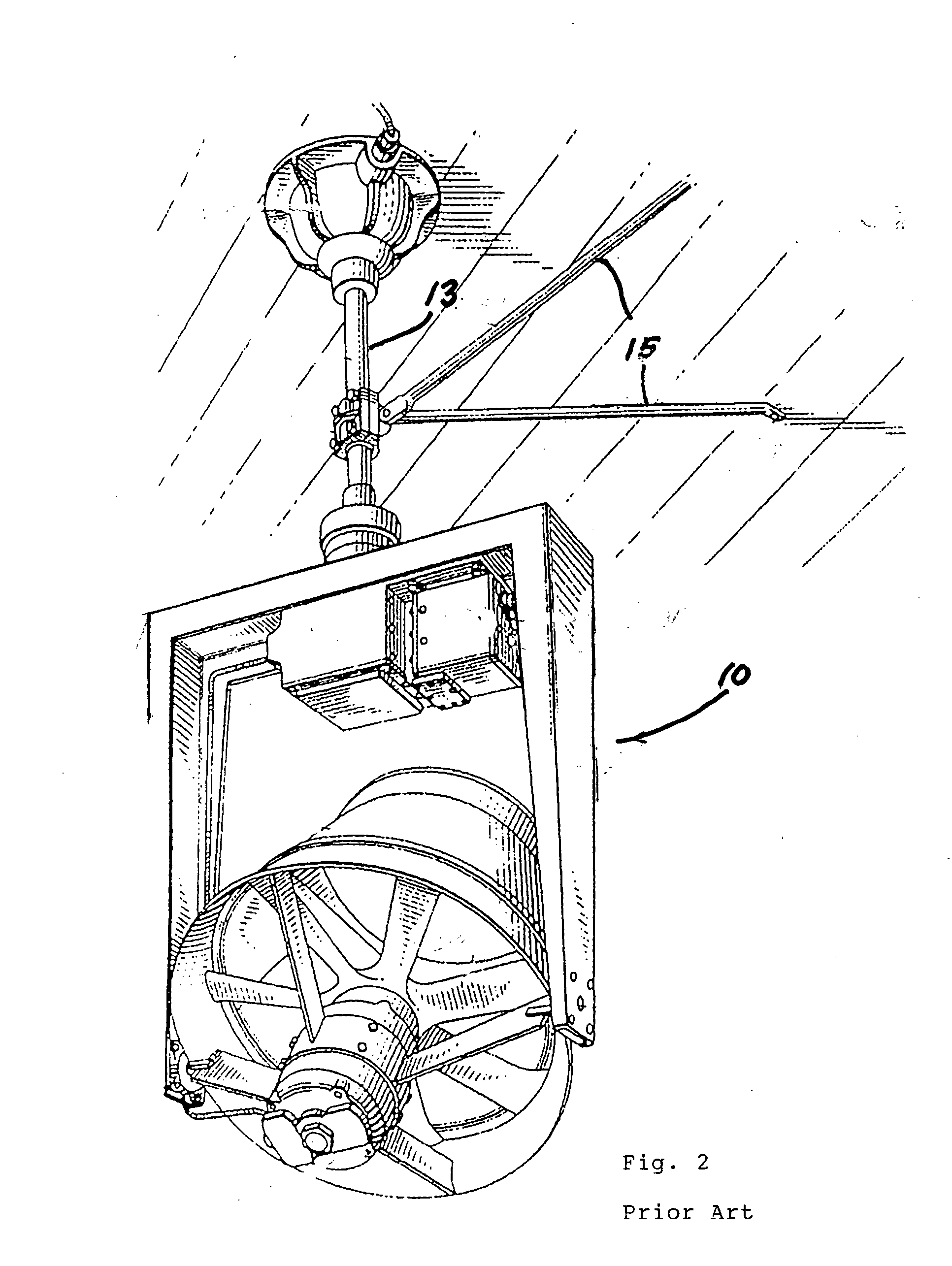

[0027] Referring now to the drawings, the present invention involves improvements in and for the ceiling cleaner fan 10 shown in FIGS. 1 and 2 which is used to control lint accumulation on the ceilings, walls, floors and machinery in textile mills, laundries and other facilities where fabrics and the like are fabricated, used or otherwise handled. Fan 10 is universally mounted and of the type that rotates as a whole about a vertical axis while the fan itself simultaneously oscillates about a horizontal axis so that the air stream from the fan oscillates through a vertical sweep angle which can extend from horizontal to near-vertical. The particulars of cleaner fan 10 and its associated components are set forth in U.S. Pat. No. 3,072,321, the contents of which are incorporated herein by reference.

[0028] In the improved version of fan 10 (hereinafter 10′) and its components, a more precise, regulated and efficient control system has been developed to maximize the positive utilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com