Tilt-up support tower

a support tower and tilt-up technology, applied in the direction of buildings, buildings, buildings, etc., can solve the problem that the tower does not have a multi-step tilt-up system, and achieve the effect of easy raising and lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

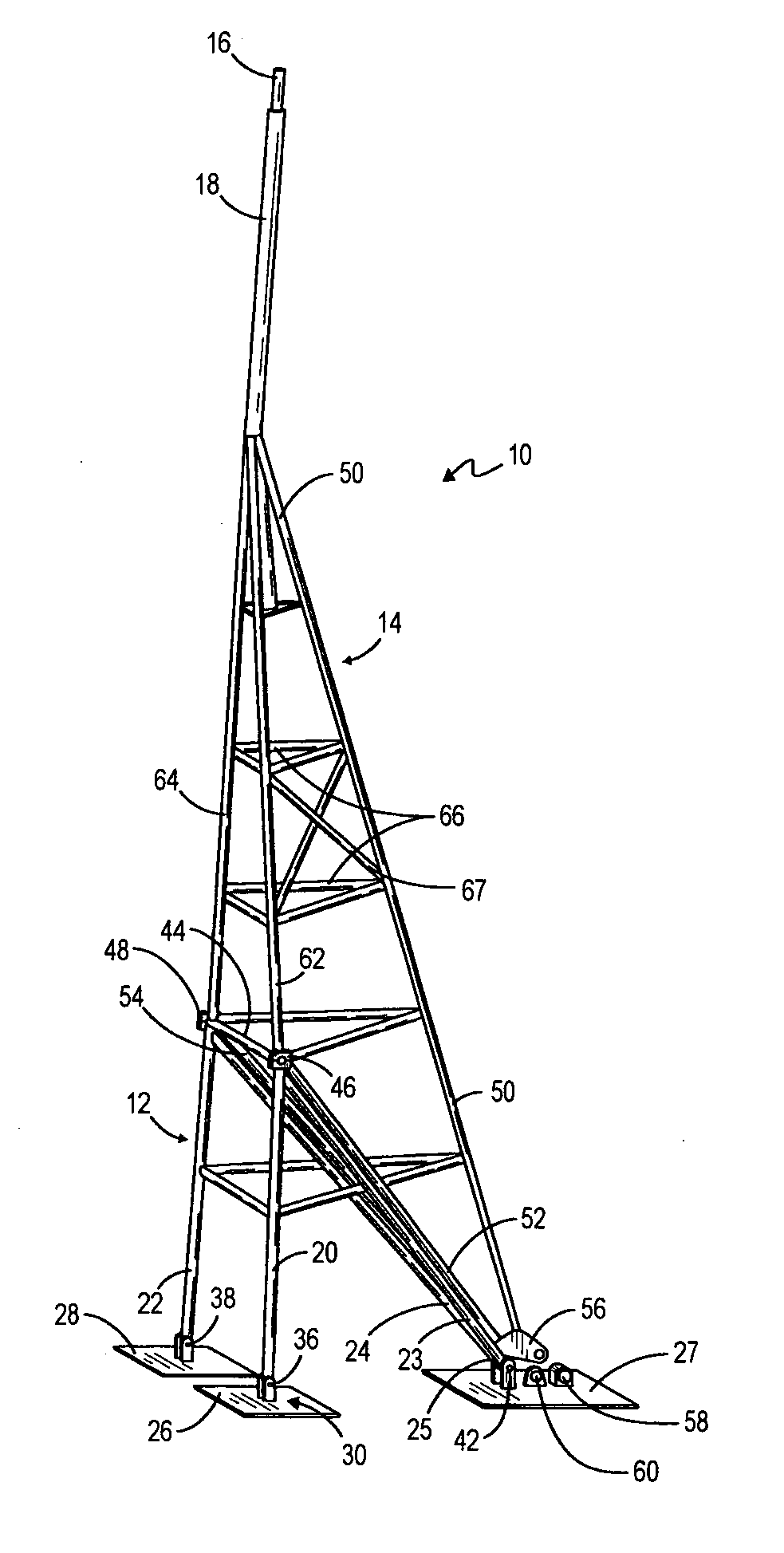

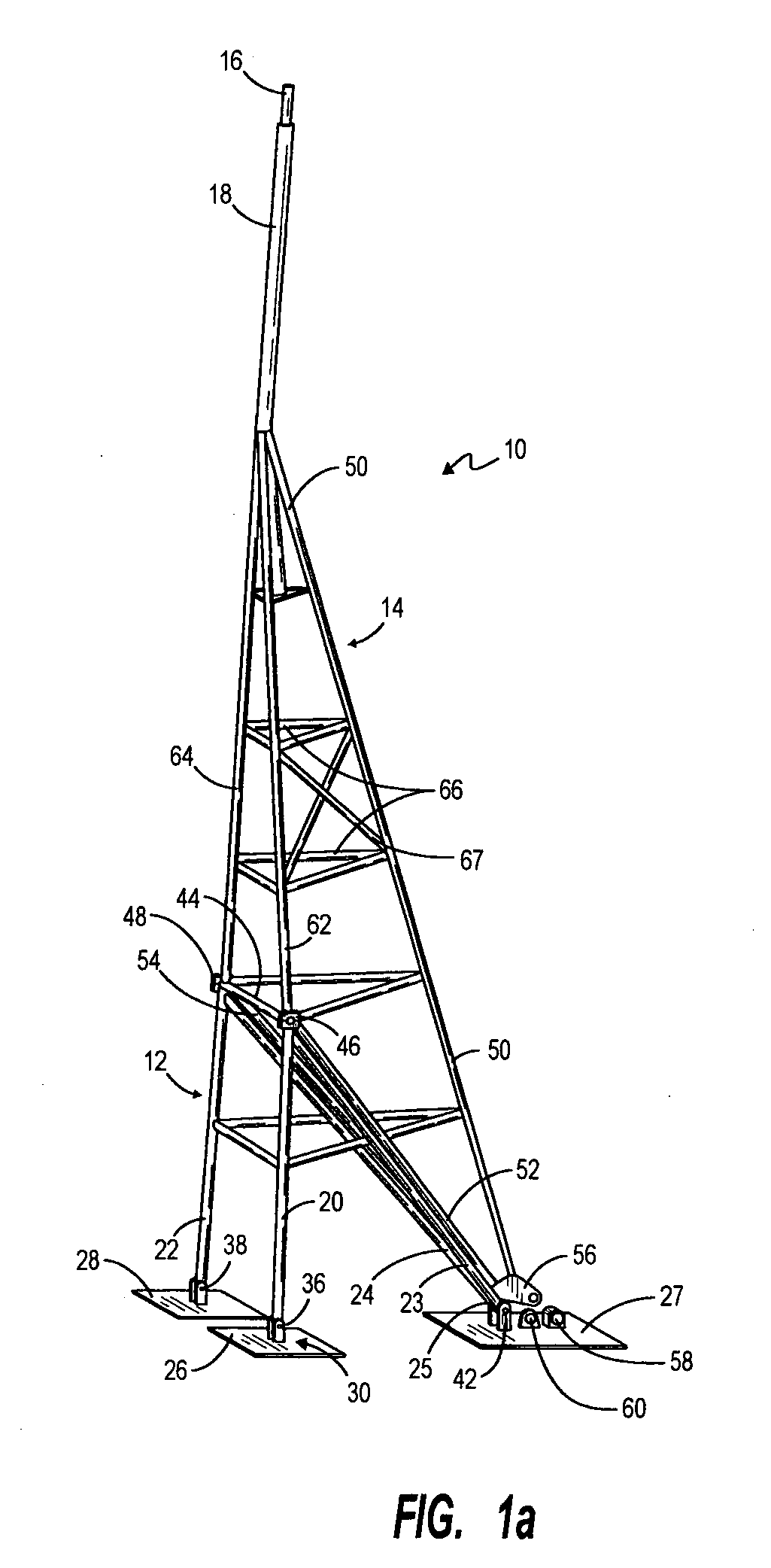

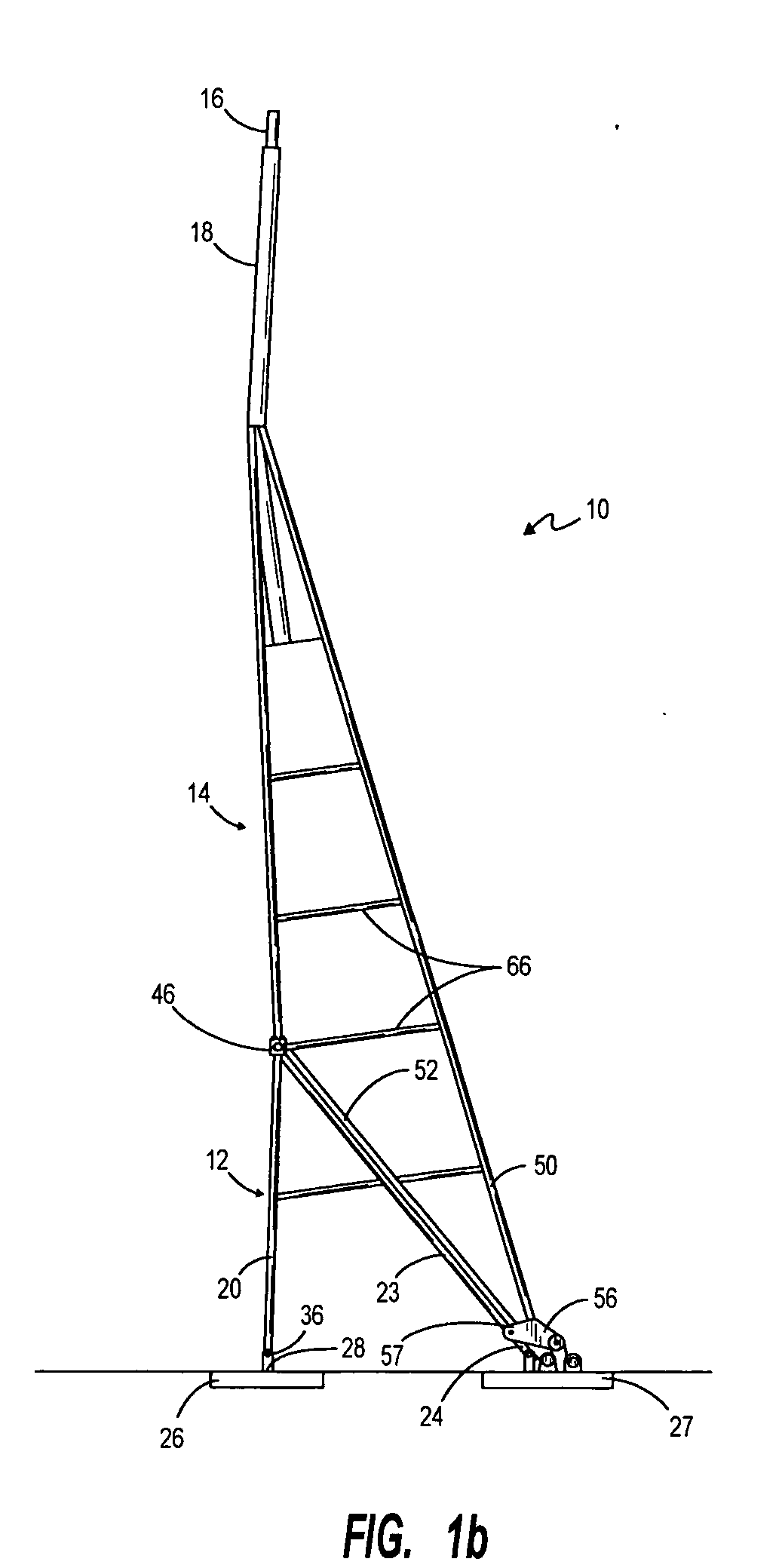

[0030] The detailed description is directed to one or more embodiments of the inventive concepts of the present invention and this material is presented as being representative of these concepts but is not intended to be interpreted as limiting with respect to any aspect of the invention. In view of the above, the embodiments of the drawings will be described. One embodiment is illustrated in FIGS. 1a-6b and alternative embodiments are shown in FIGS. 7 and 8a-12.

[0031]FIGS. 1a and 1b illustrate in schematic form perspective and side elevational views of an embodiment of a collapsible, tilt-up support tower assembly shown in the fully deployed or elevated position. The support tower assembly, generally denoted by the reference character 10, includes a lower tower section or tower base section 12 and an upper tower section 14. The upper tower section 14 carries a vertically disposed mast 16 supported from and secured to a support member or tower tube 18. Tower tube 18 and mounting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com