Self-stick metal plate and method of applying the same

a self-sticking, metal plate technology, applied in the direction of roofs, washers, constructions, etc., can solve the problems of weak points in the waterproofing system, the cost penalty of the adhesion system, and the deterioration of the mechanical fastening membrane, so as to improve the resistance to wind uplift forces, improve the durability, and prevent the effect of leaking in the roof structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

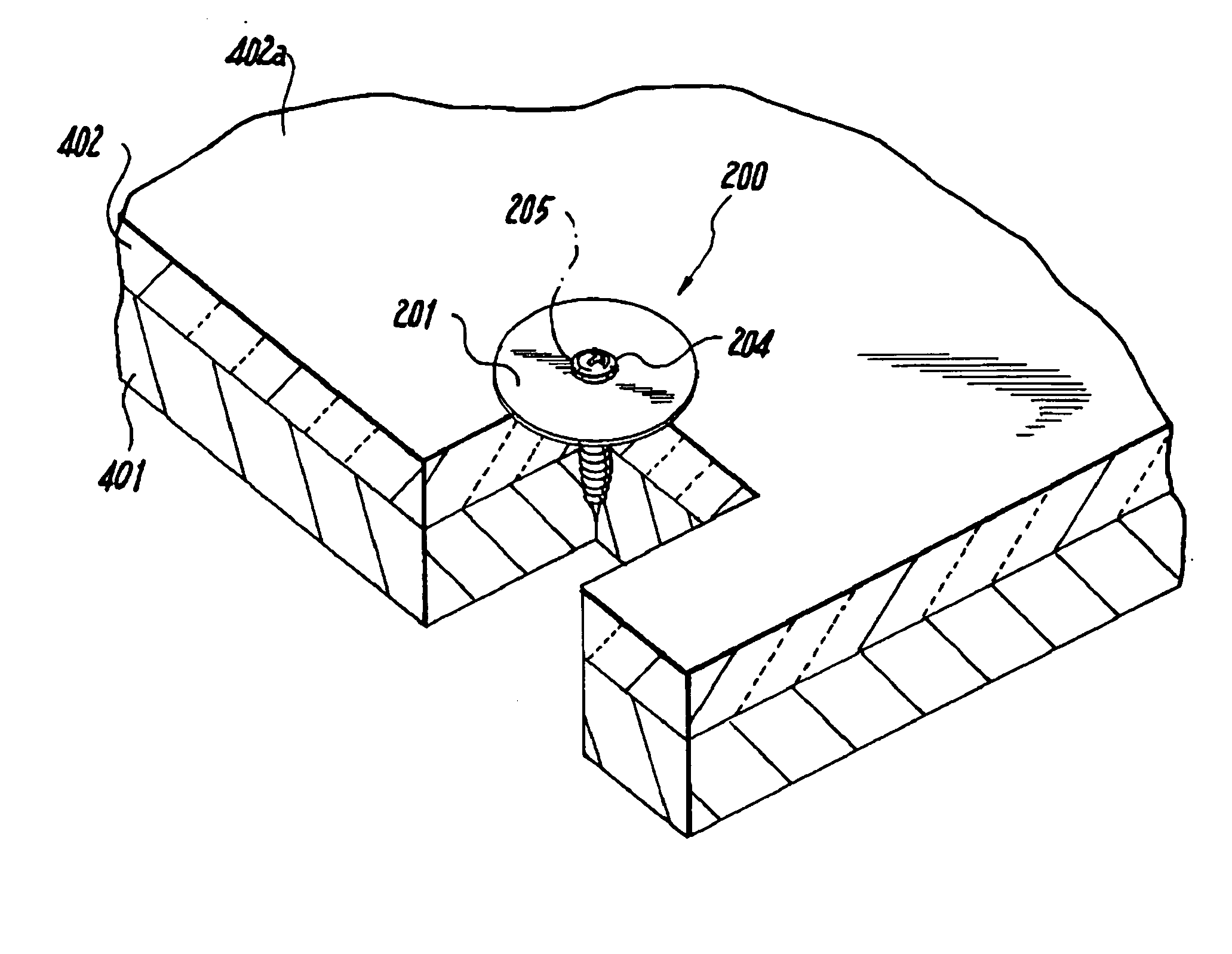

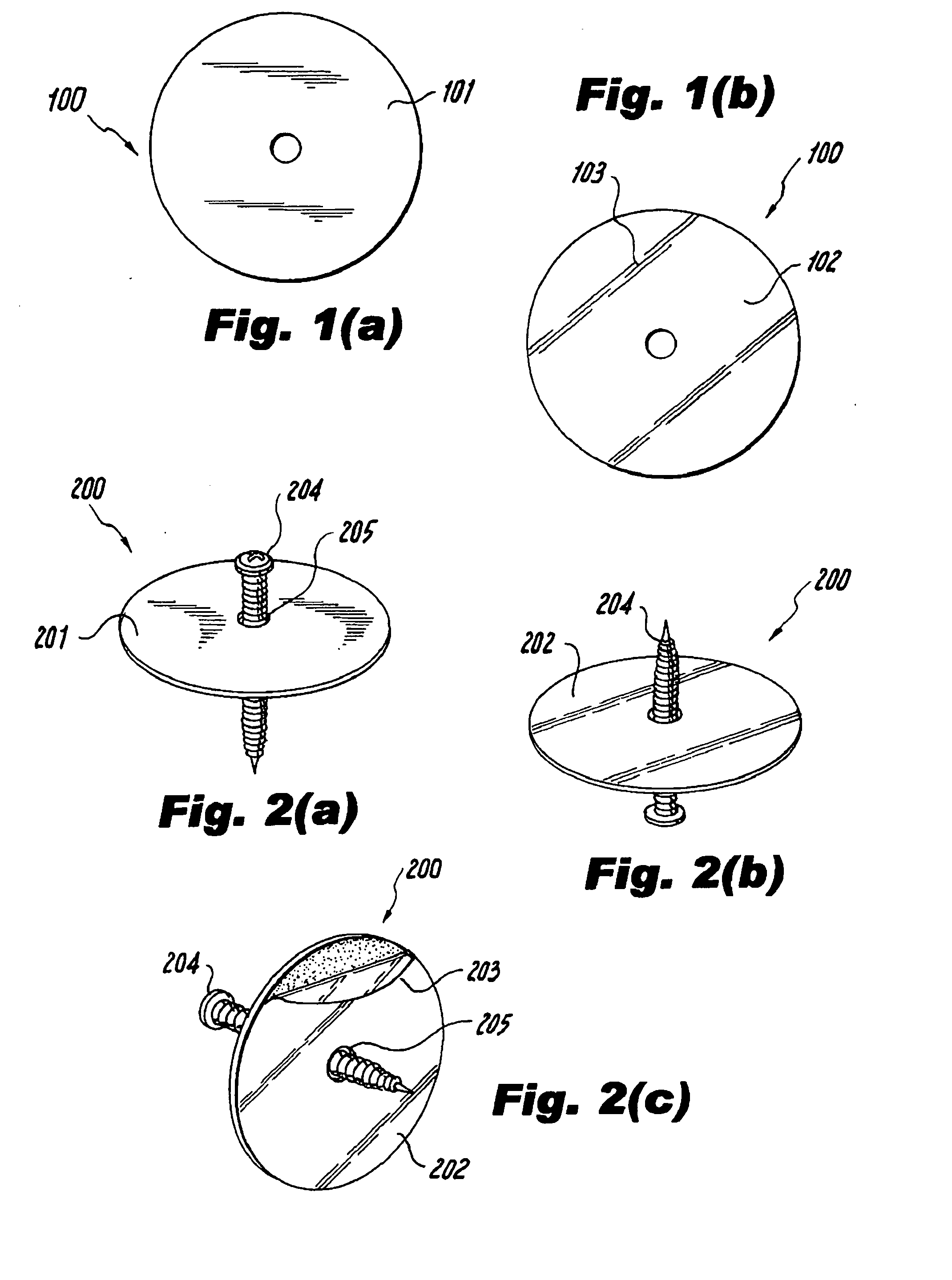

[0030]FIG. 2(a) illustrates the metal plate of the present invention having a fastener. FIG. 2(a) shows a metal plate 200 having a top side 201 which can have a coated layer. Additionally, a fastening device 204 is provided at the center 205 of the metal plate 200. Any known fastening device 204 can be used as known to one of ordinary skill in the art, such as a screw. The fastening device 204 preferably goes through the center 205 and through the entire metal plate 200 from the top side 101 extending through the bottom side 102, and screws onto the roof deck to attach the metal plate 200 to the roof deck.

[0031]FIG. 2(b) illustrates a side view of the second embodiment of the metal plate 200. FIG. 2(c) illustrates a bottom view of the second embodiment of the metal plate 200, having a bottom side 202 and a film 203 that covers the adhesive layer on the bottom side 202 of the metal plate 200. The mechanical fastener 204 penetrates through the entire metal plate 200 through the center...

first embodiment

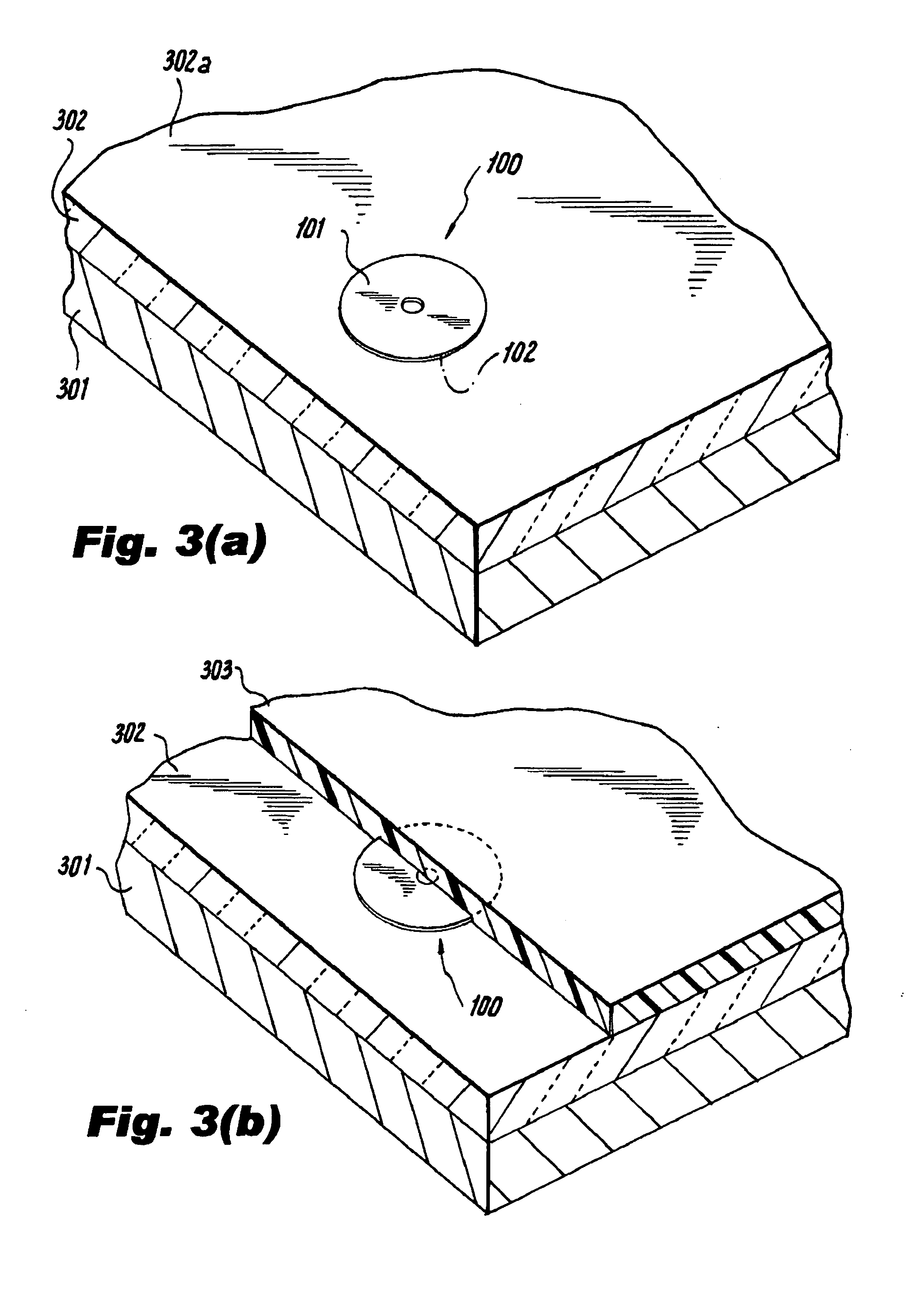

[0032] A method of application of the metal plate of the present invention is illustrated in FIGS. 3(a)-3(b). As shown in FIG. 3(a), the metal plate 100 is to be positioned upon the roof deck 301. As known in the art, insulation 302 may be applied over the roof deck 301 as desired. Examples of suitable insulation materials include polyurethane, polystyrene, wood fiberboard, polyisocyanarate and the like. Usually, at an outer perimeter of the roof deck 301 is a wall (not shown) which extends generally perpendicularly upward from the roof deck 301 above the plane of the roof deck 301.

[0033] The film 103 is then removed from the bottom side 102 of the metal plate 100, and the bottom side 102 is attached to the top surface 302a of the insulation 302. The adhesive layer on the bottom side 102 of the metal plate 100 attaches the metal plate 100 to the insulation 302, or roof deck 301 if insulation 302 is not used. The top side 101 has a coated layer, as described earlier.

[0034] As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com