Circumferential flow pump

a flow pump and circumferential flow technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of impeller lock, large volume of alcohol and toluene swelling, and clogging of injection molding resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

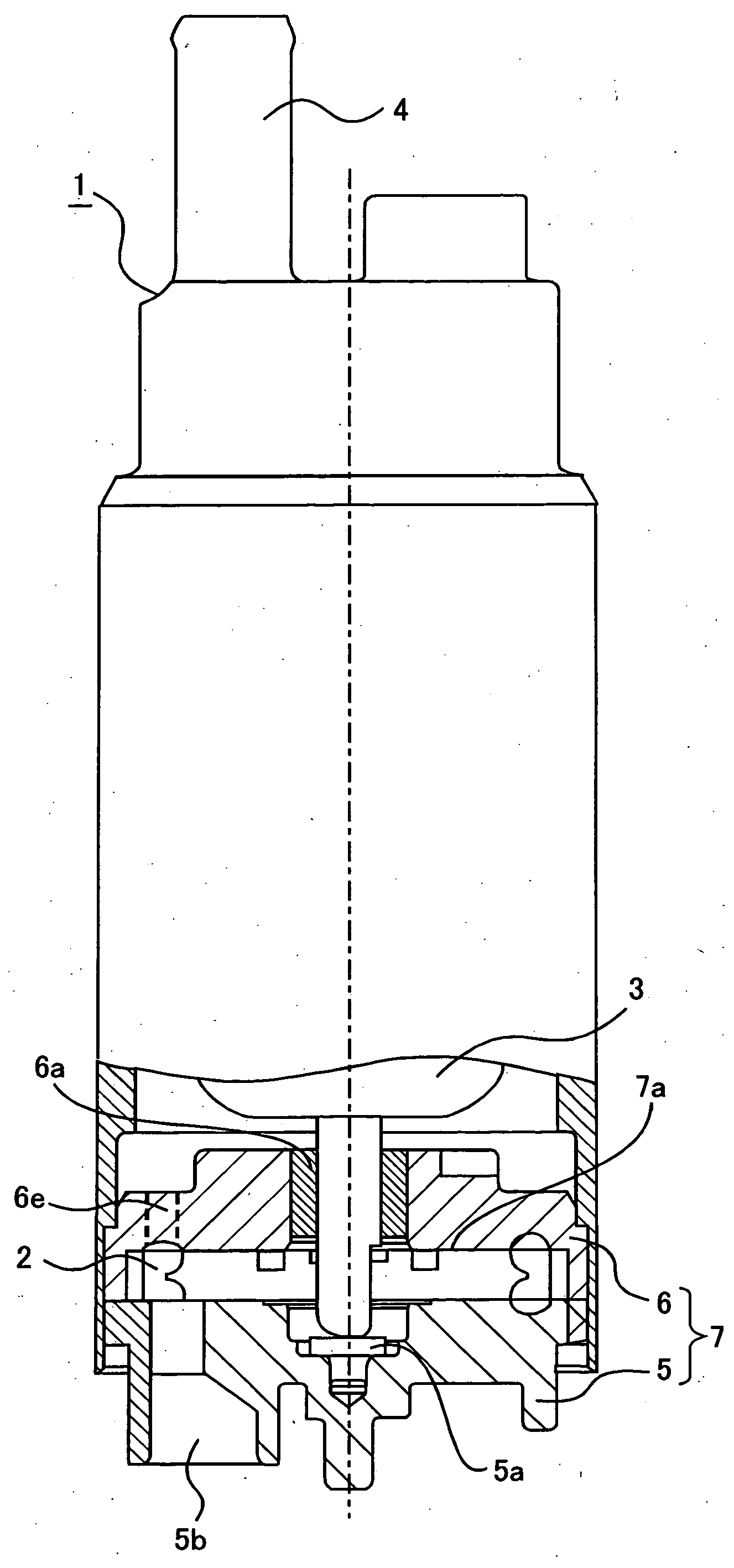

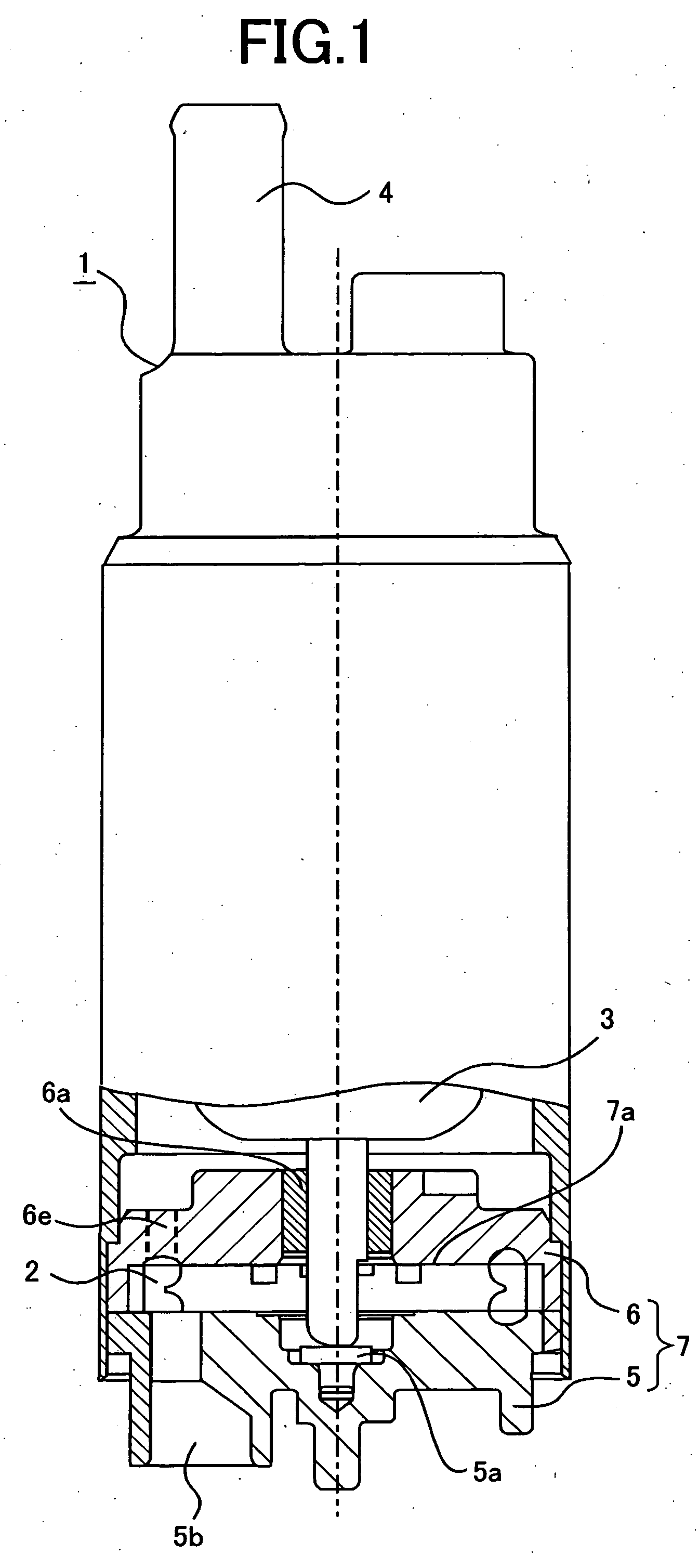

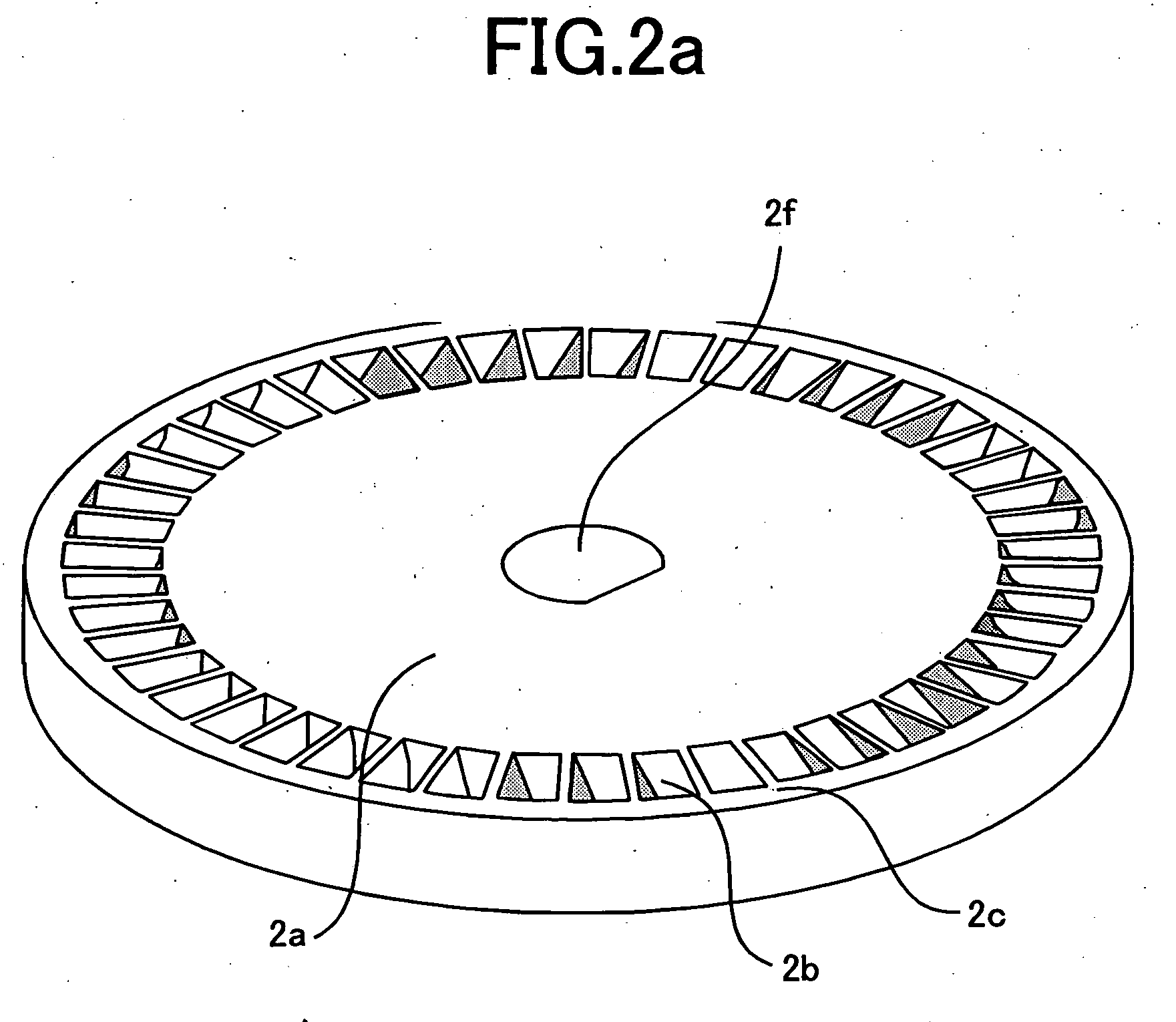

[0017]FIG. 1 is a partially sectional elevation view illustrating a circumferential flow pump in Embodiment 1. The circumferential flow pump 1 includes: a disc-shaped impeller 2 fitted to the motor rotor 3; and a pump-housing 7, composed of a pump cover 5 and a pump base 6 for housing the impeller 2. In the pump cover 5, a thrust bearing 5a is placed at the center thereof for bearing in the thrust direction the shaft of the motor rotor 3, and an inlet 5b is provided at the bottom of the cover for leading from a fuel tank, fuel into the impeller 2. At the center of the pump base 6, a metal member 6a is placed for bearing the rotating shaft of the rotor 3.

[0018]When the motor rotor 3 is driven with the pump 1 being immersed in the fuel tank, the fuel is led from the inlet 5b into the pump room by the rotation of the impeller 2. Through an outlet 6e of a pump room and the motor room, the fuel is sent from a spout 4 to the internal combustion engine. In addition, in order to prevent the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com