Rock drill water separator

a technology of dust suppression apparatus and rock drill, which is applied in the direction of fluid removal, earth-moving drilling, and well accessories, etc. it can solve the problems of affecting the environment, workers and mechanical equipment, and wear on the cutting services, and achieve the effect of facilitating water evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

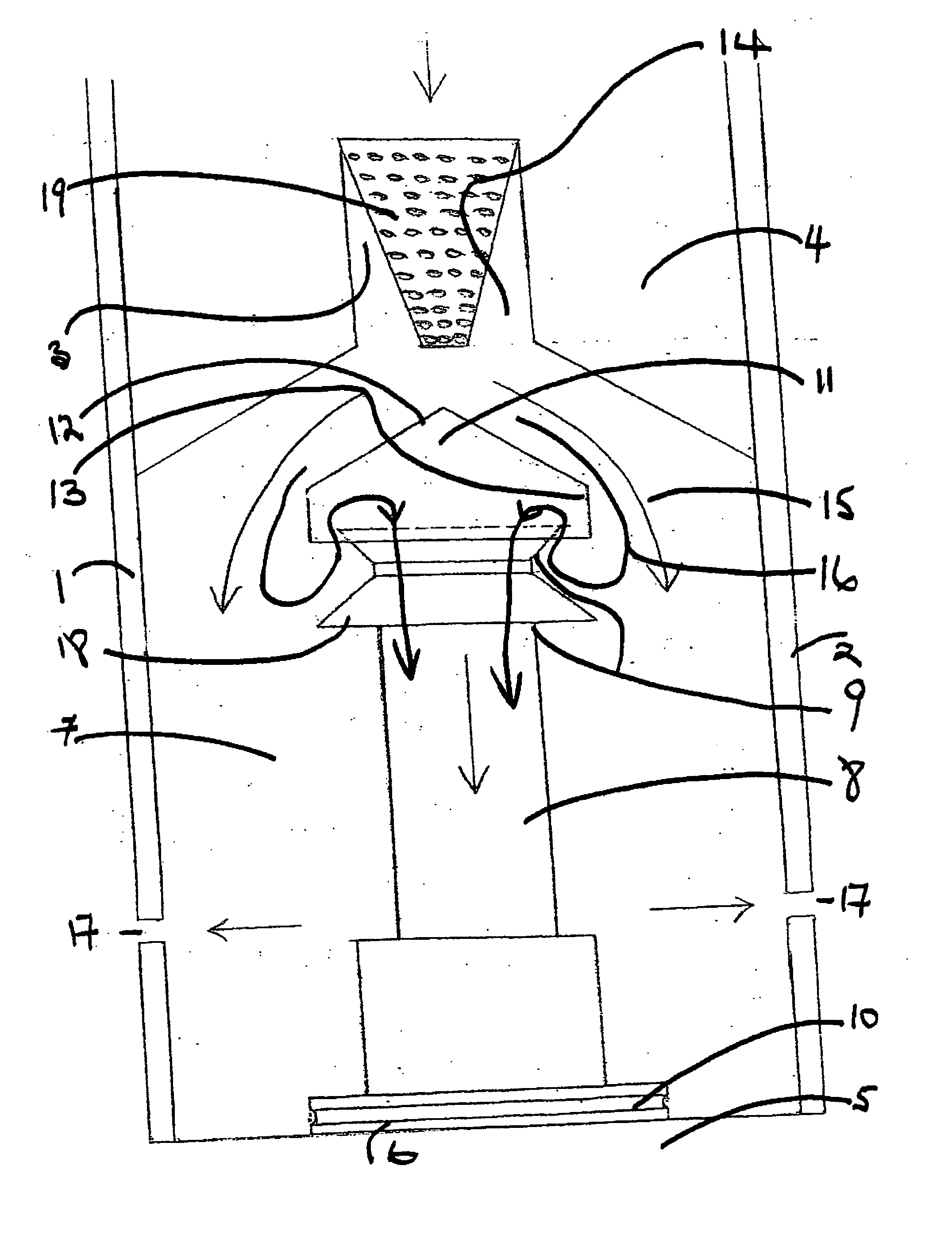

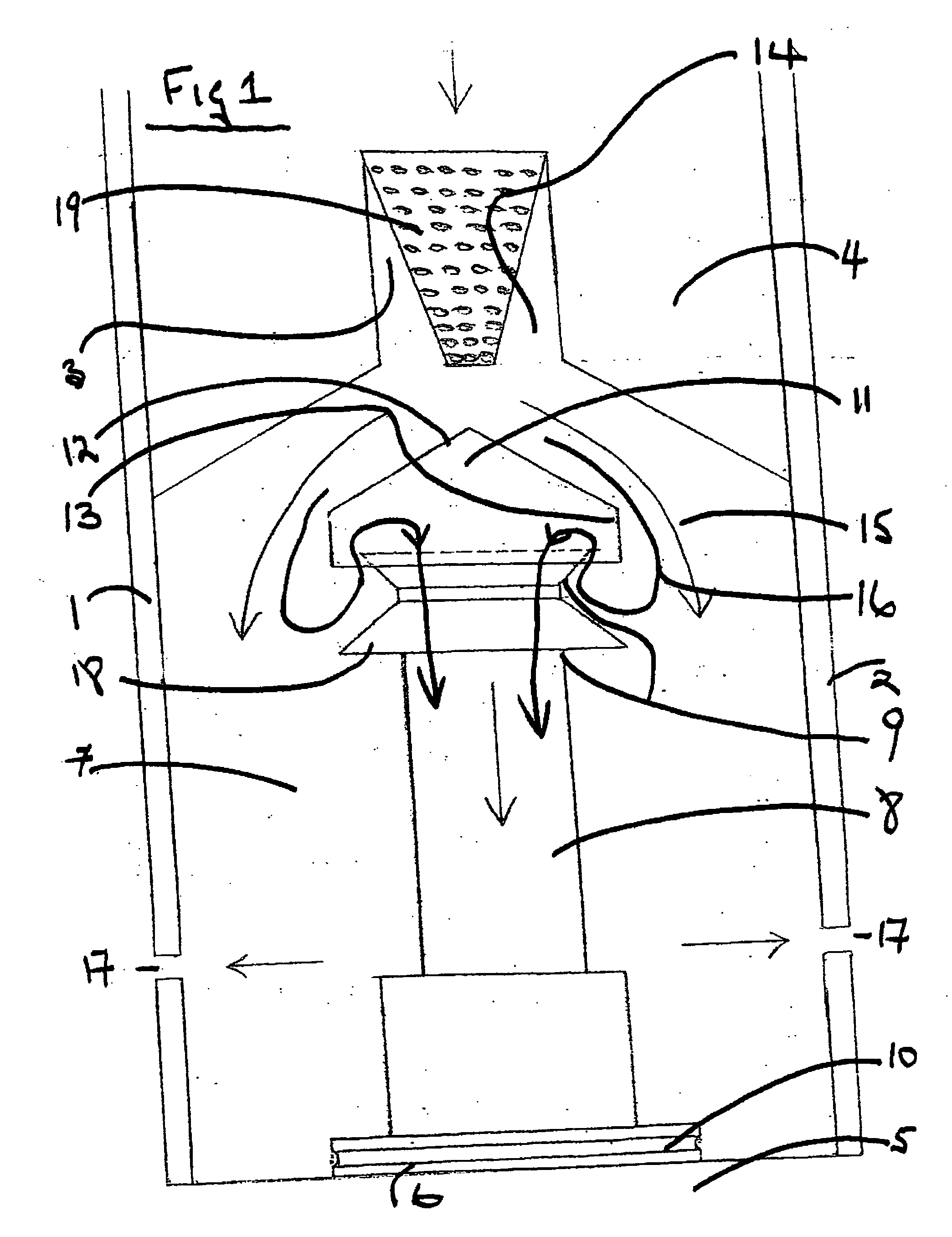

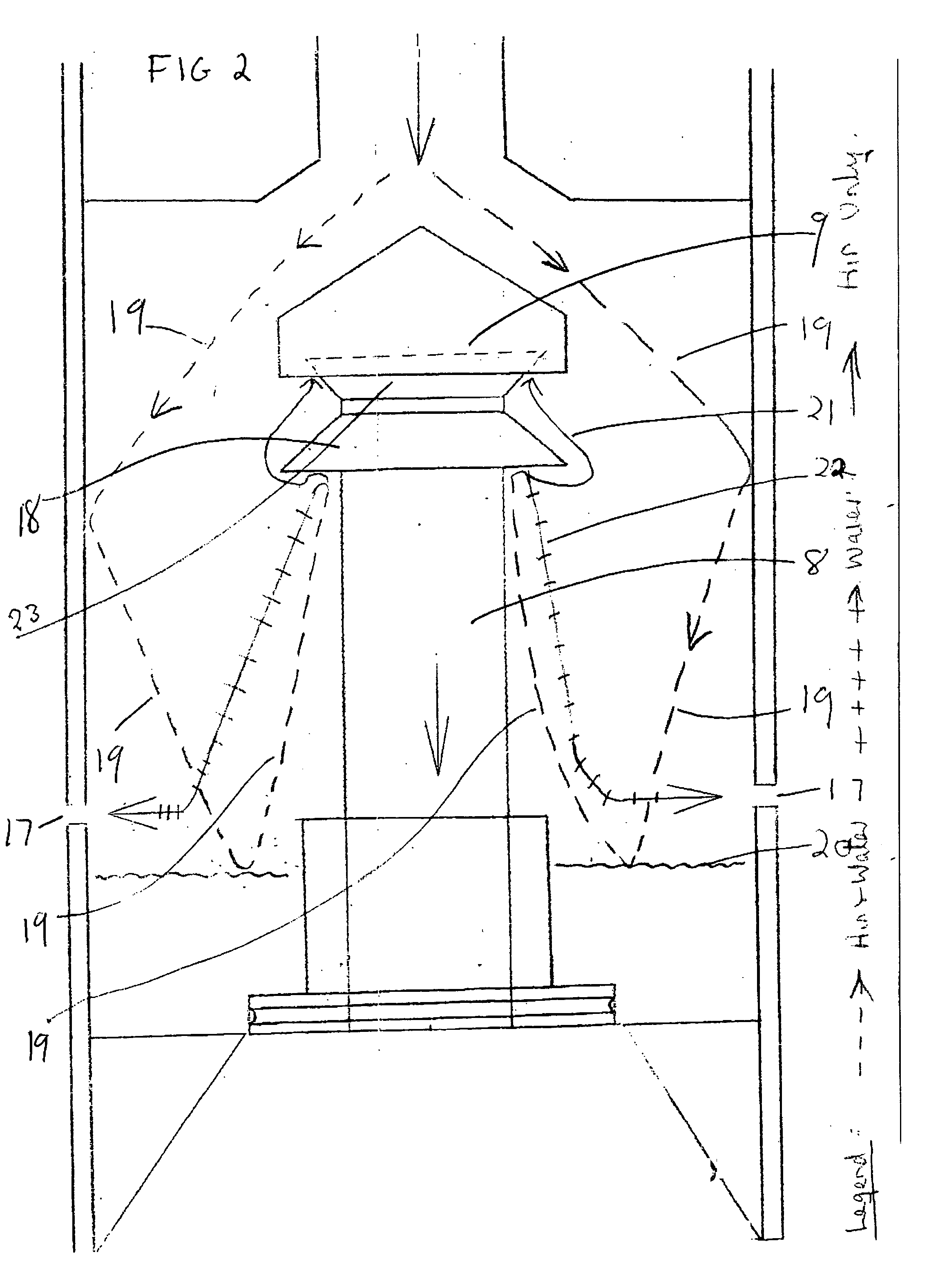

[0010] According to the embodiment of FIG. 1 there is disclosed a dewatering module 1 comprising an outer tubular housing 2 and an air / water inlet 3 adjacent first end 4 thereof. The second end 5 of the module is adapted to receive a drill bit (not shown) in a standard mount 6.

[0011] The module 1 defines a chamber 7 which in turn contains an inner tubular housing 8 extending from a first inlet end 2 to a second outlet end 10 adjacent the drill bit (not shown). The inlet end 9 of inner tubular housing 8 is covered by baffle 11 comprising conical hat portion 12 and depending skirt portion 13. It will be observed that the diameter of depending skirt 13 is greater than that of the inlet 9 to inner tubular housing 8 hence allowing passage of air between the skirt and the outer and upper extremities of tubular housing 8.

[0012] In use the module operates by receiving a pressurised air / water flow through inlet 3 in the direction indicated by arrow 14. This flow is directed onto the centre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com