System and process for detecting a load of clothes in an automatic laundry machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

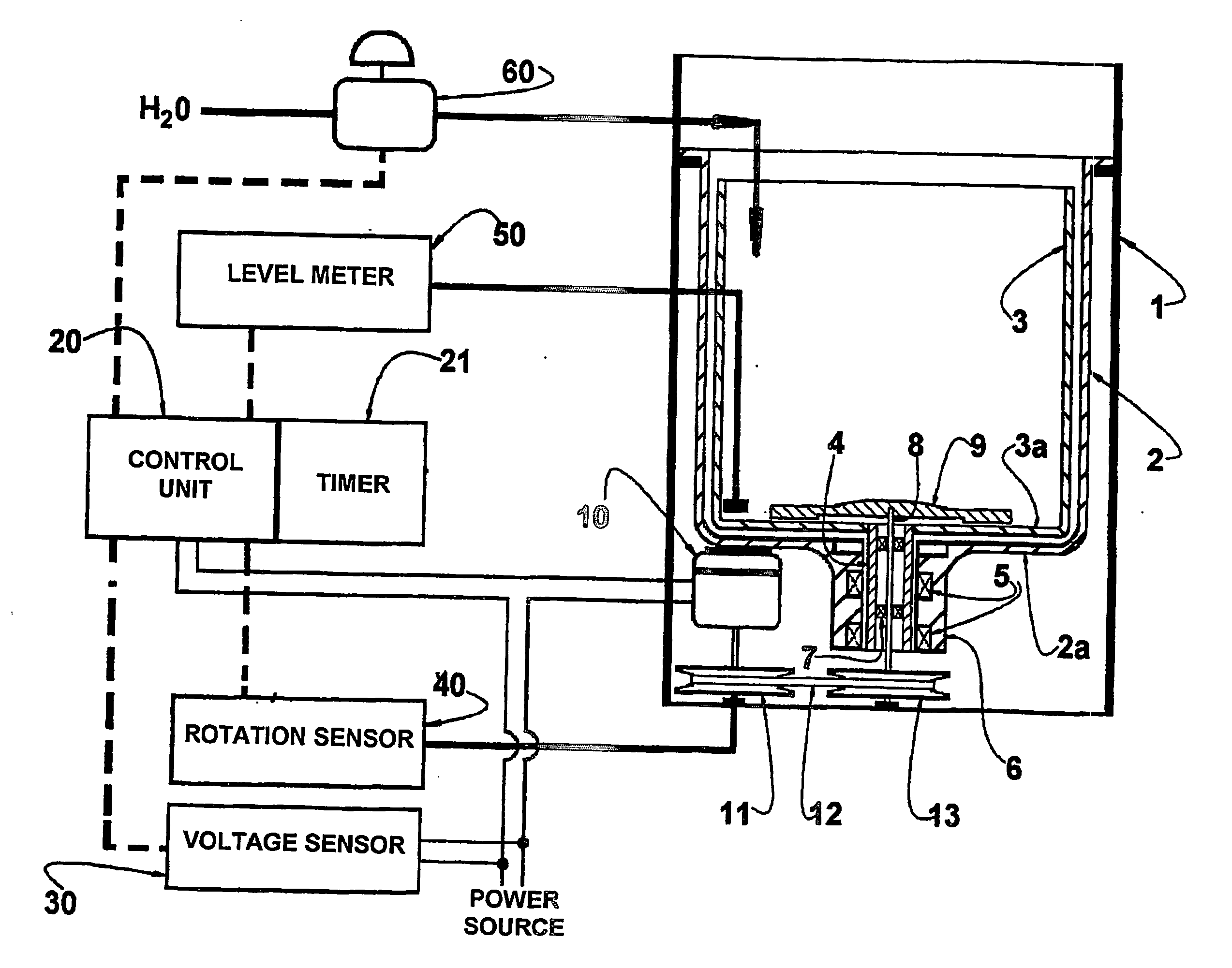

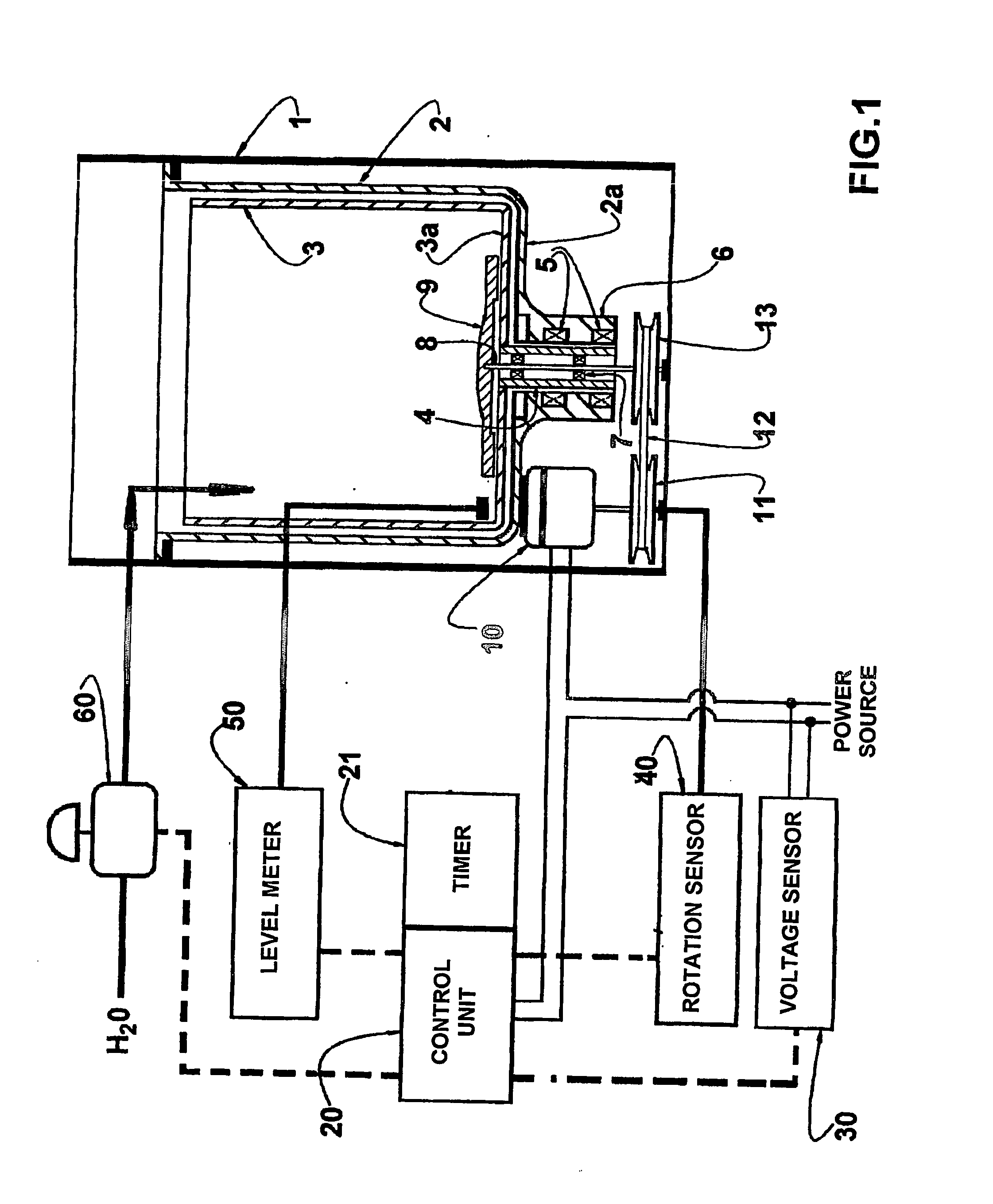

[0035] As mentioned above and illustrated in FIG. 1 of the drawings, the present system for detecting a load of clothes is applied to an automatic laundry machine of the type which comprises a structural casing 1, generally defined by a prismatic cabinet, within which is mounted, through suspension means, not illustrated and which may present any adequate construction belonging or not to the state of the art; a tub 2, generally cylindrical and within which is coaxially rotatively mounted a basket 3, generally in the form of a cylindrical drum, having perforated lateral and bottom walls and which is superiorly open and dimensioned to contain a load of clothed to be washed. In the laundry machines with a vertical shaft, such as that illustrated, the basket 3 has its bottom wall 3a centrally affixed to a tubular shaft 4 projecting vertically downwardly and outwardly from the tub 2, so as to be supported by bearings 5 mounted on a bearing support 6 secured to the bottom wall 2a of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com