Monitoring formation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

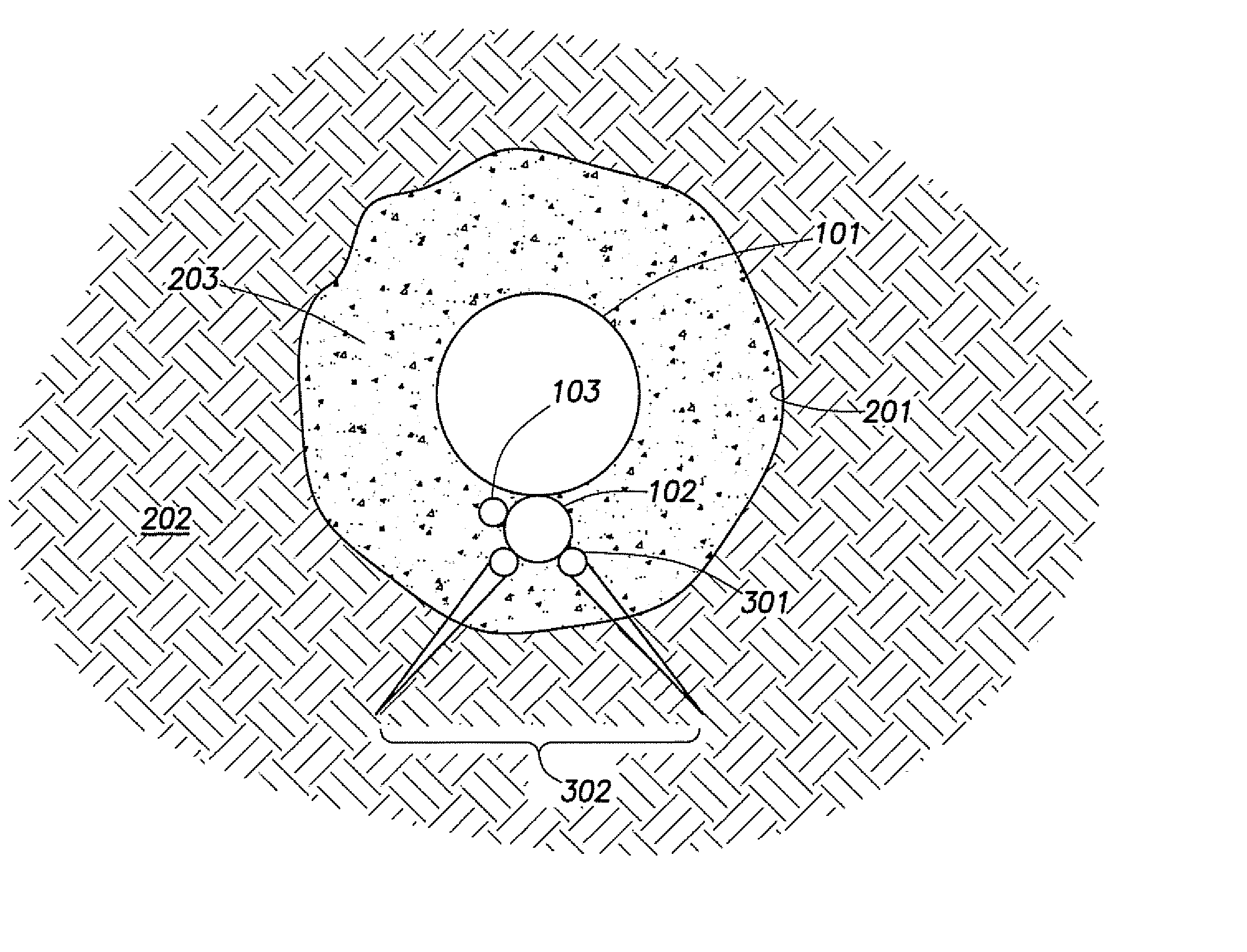

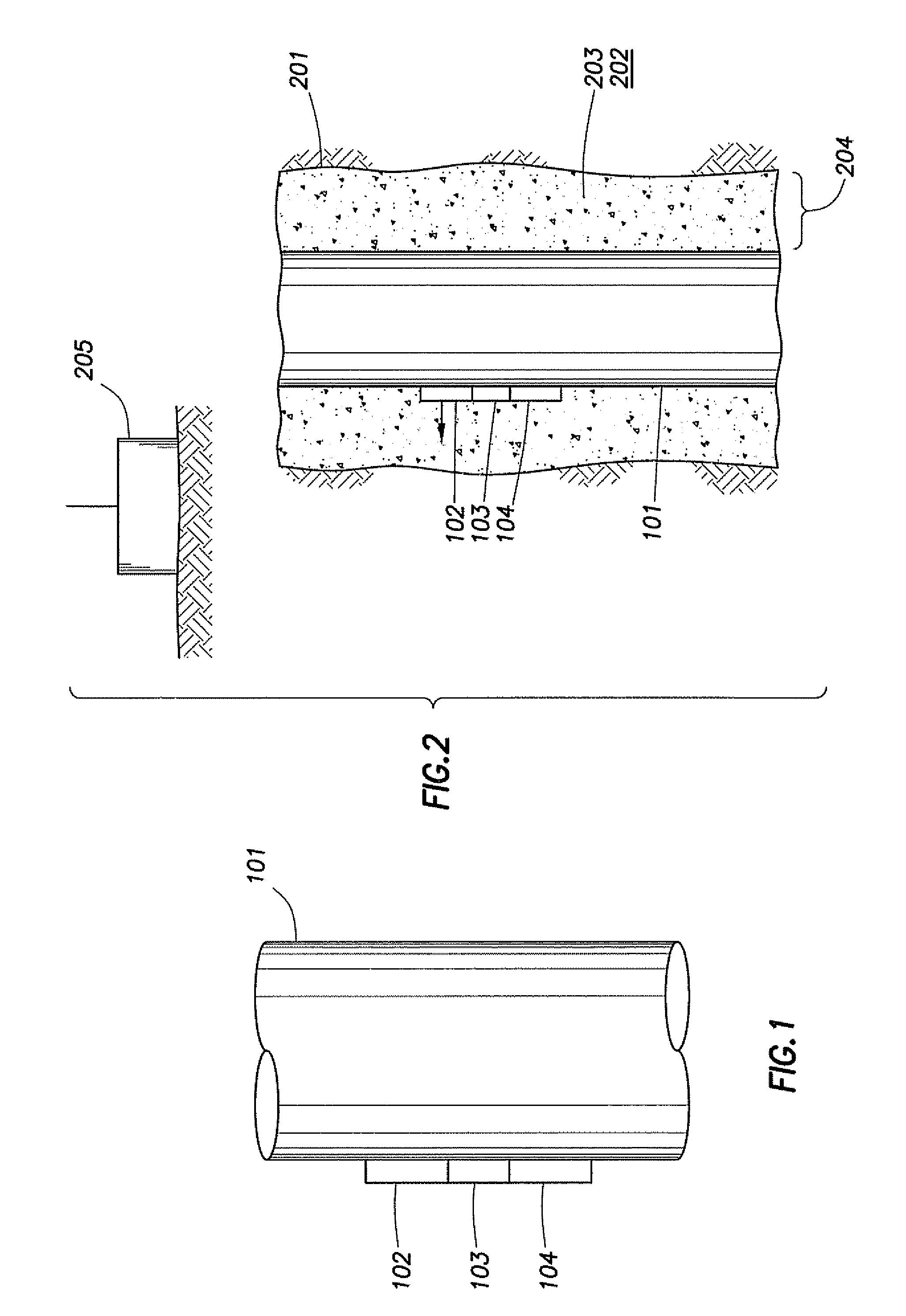

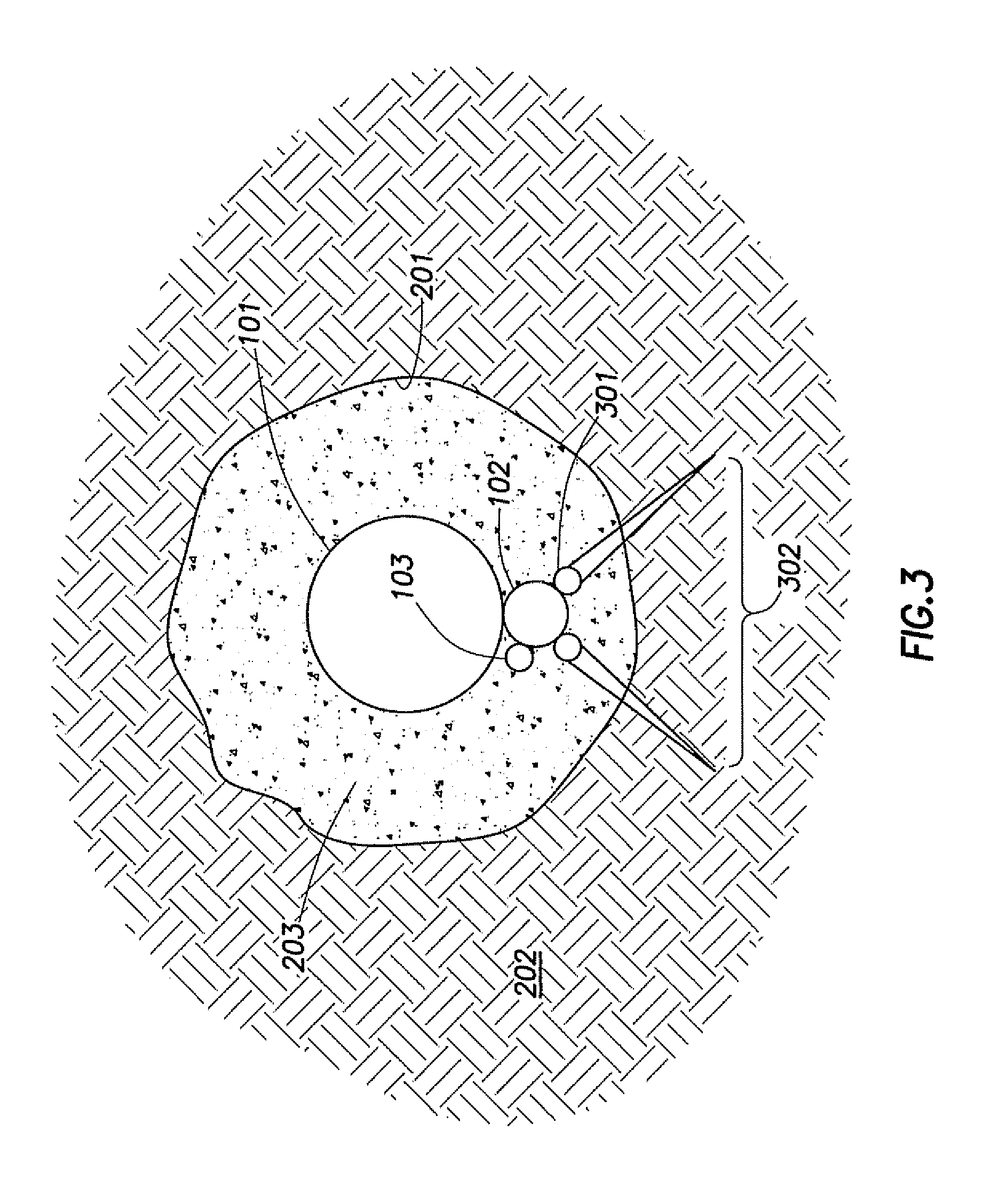

[0017]FIG. 1 shows one embodiment of an apparatus for monitoring formation properties. In this embodiment, tubular element 101 is a section of casing, liner, or other material used to maintain the integrity of the wellbore. Tubular element 101 may also be a section of tubing, cement stinger, or other device used to lower equipment into a wellbore. Perforating gun 102 and sensor 103 are mounted on the outside of tubular element 101 in close proximity to one another. Perforating gun 102 and sensor 103 may be connected either directly or via additional tubulars or hoses.

[0018] Any type of perforating gun may be used; however the direction of the perforations must point away from the casing (tubular element 101) so that when fired, the perforating gun does not damage the casing. In a wireless embodiment of the invention, perforation gun 102 may be fired by pressuring up the casing using conventional methods of wireless perforating. In an alternative embodiment, a wire may be attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com