Cleaning implement

a technology for cleaning implements and hard surfaces, applied in the direction of carpet cleaners, window cleaners, cleaning equipment, etc., can solve the problems of difficult to adapt devices for continued use, multiple devices are required, and difficult to remove, so as to facilitate cleaning, facilitate quick attachment and removal, and minimize evaporation from the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

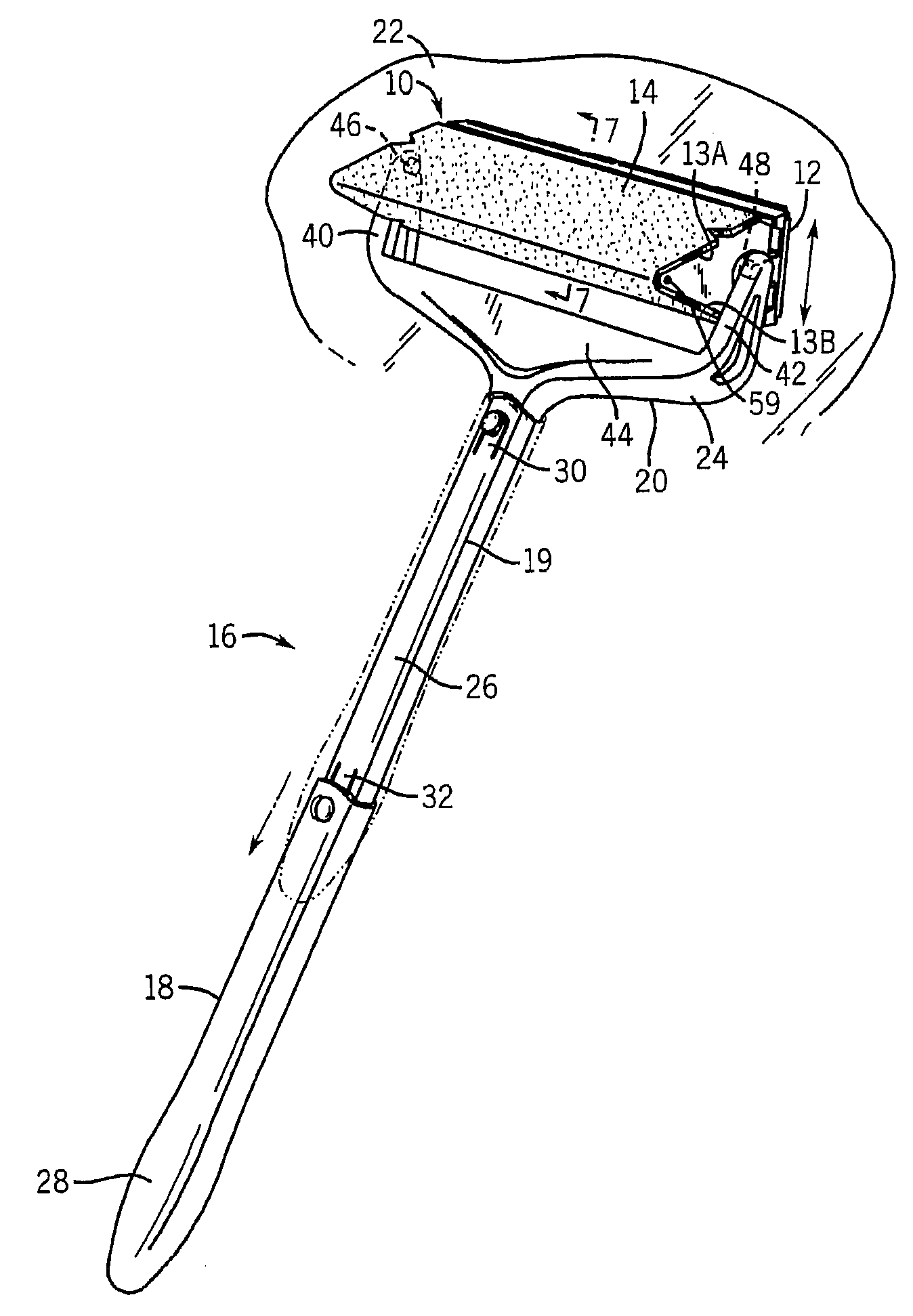

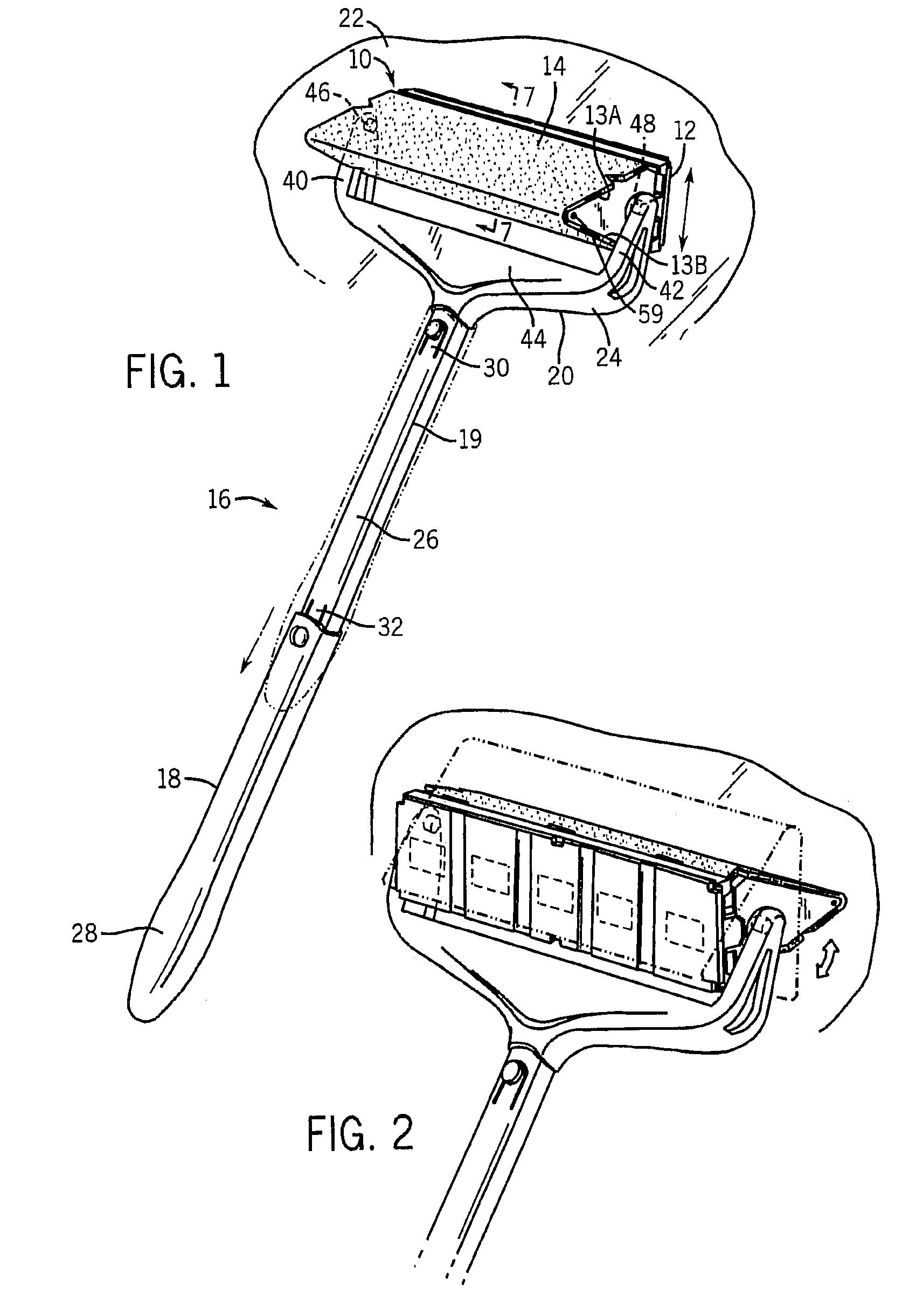

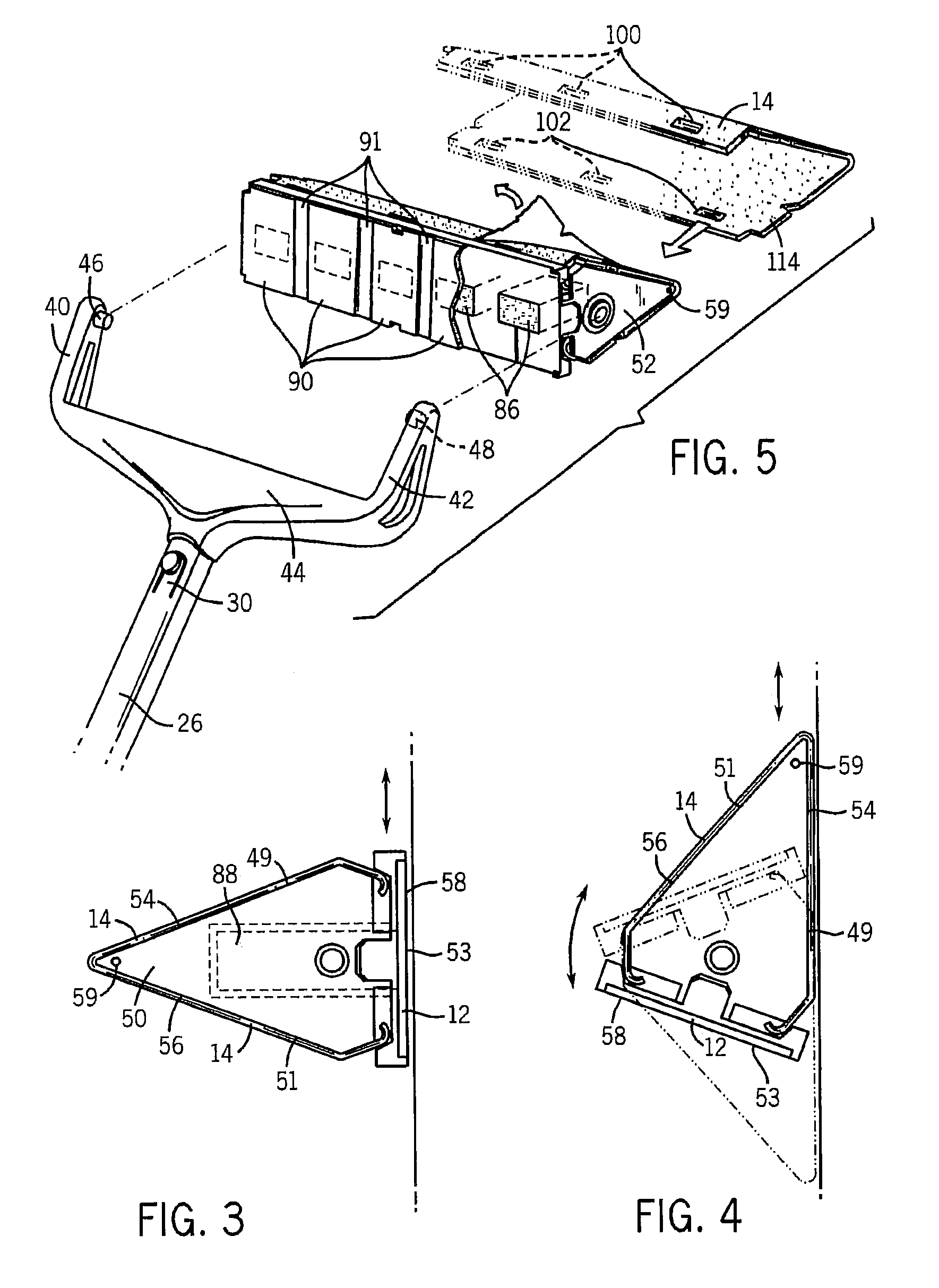

[0046]Turning first to FIGS. 1-4, a generally triangular cross section cleaning implement is shown having a support head (generally 10) with one side being a substrate 12 for applying a cleaning liquid, and two sides 13A / 13B being covered by a stack of absorbent tear-off sheets 14. There is also a handle structure (generally 16) having a lower end 18 and an upper end 19 linked to a fork 20.

[0047]The support head 10 is rotatably mounted between the arms 40 and 42 to align the impregnated substrate 12 with a surface to be cleaned (such as a window glass surface 22). When holding the handle lower end 18 the substrate 12 can be pressed against and dragged on the window glass surface 22, thereby applying cleaning liquid to the surface and to some extent scrubbing the surface to help remove stains and other deposits.

[0048]Next, the support head 10 can be rotated as shown in FIGS. 2 and 4 to align one of the tear-off sheet sides with the glass surface 22. A sheet 14 can then be pressed aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com