Modular solar energy-collecting enclosure element, and modular system for forming solar energy-collecting enclosures on buildings

a solar energy and enclosure element technology, applied in the direction of solar heat collectors with working fluids, sustainable buildings, collector casings, etc., can solve the problems of increasing the final cost of products, welds, and weak joints between plates using adhesives,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

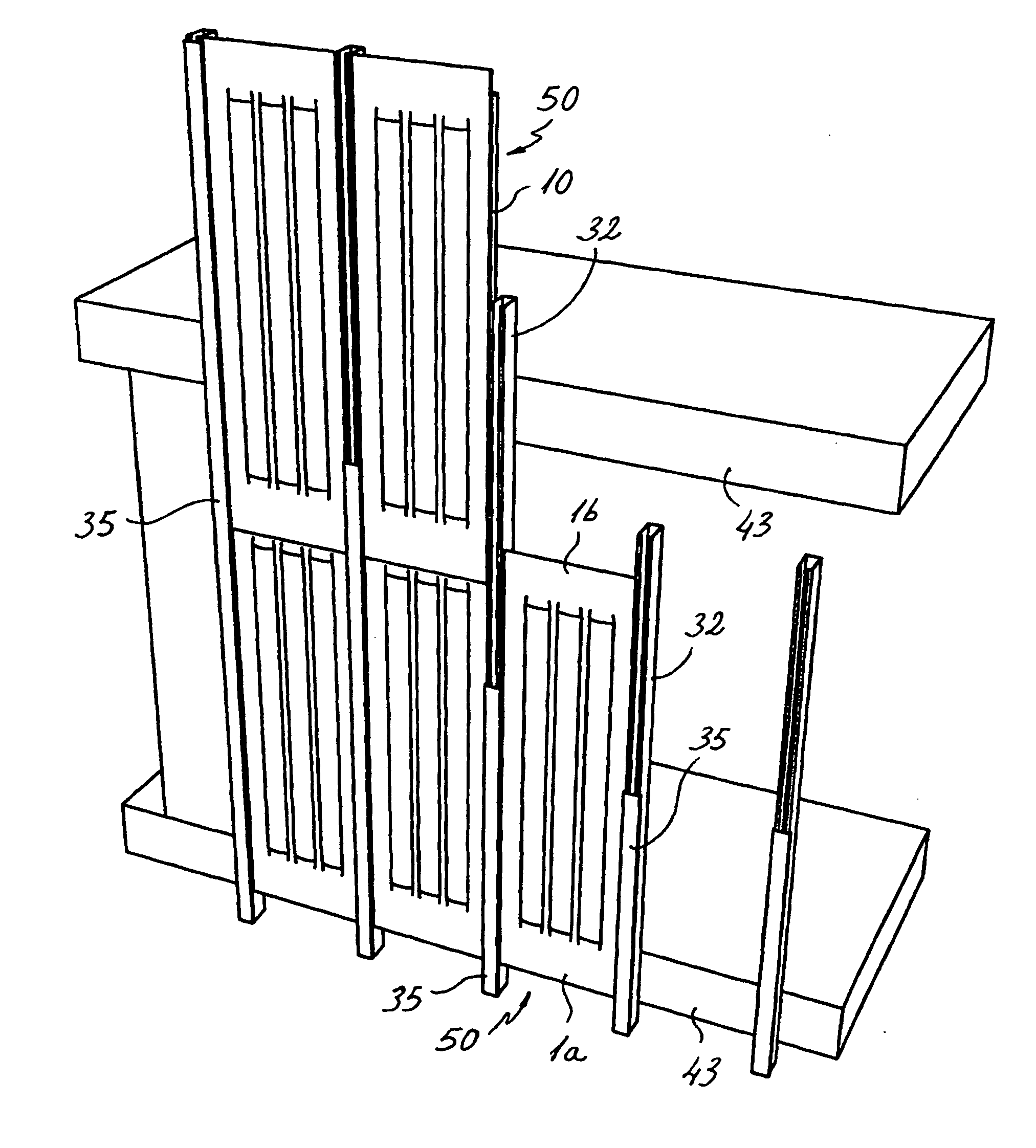

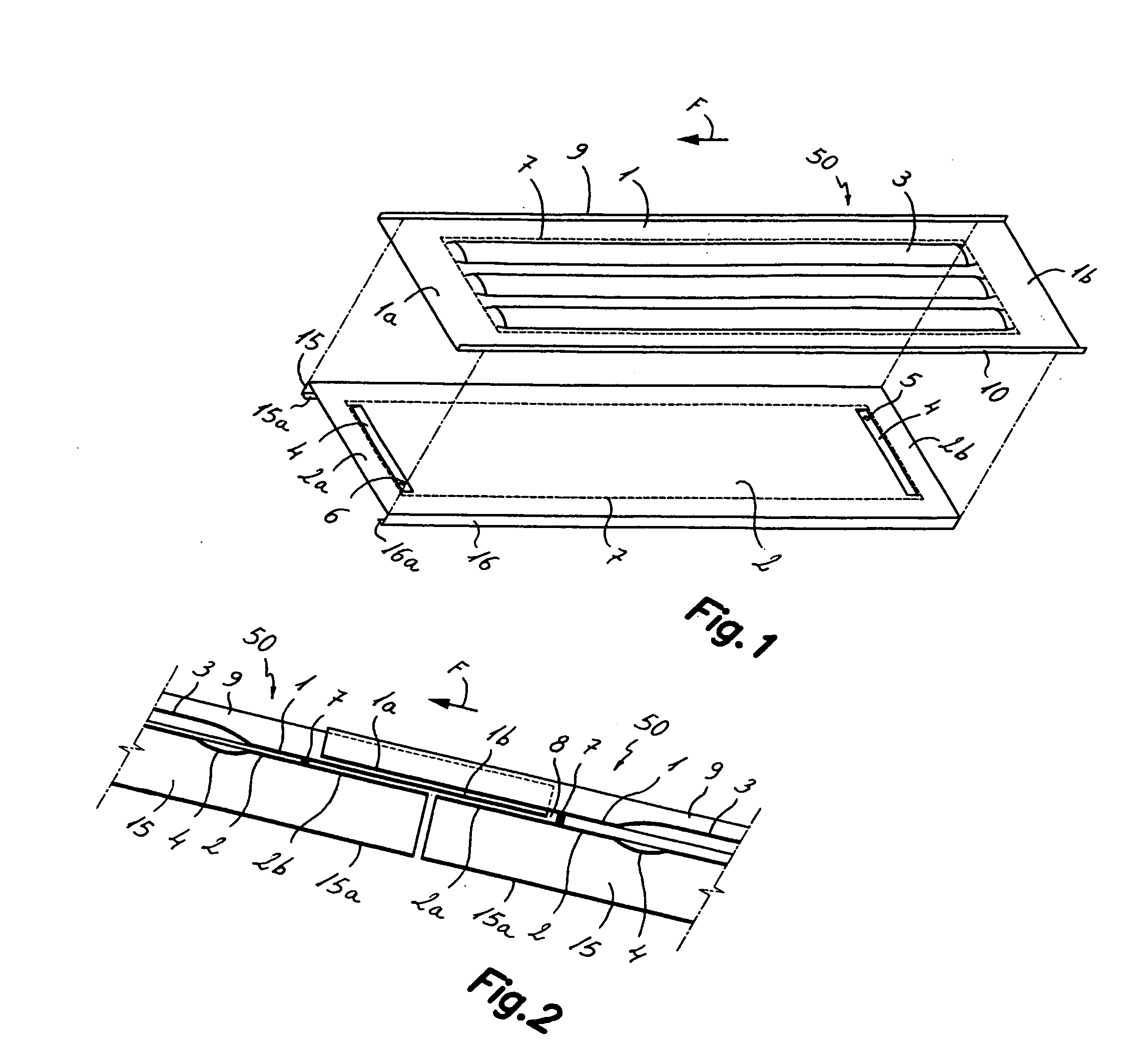

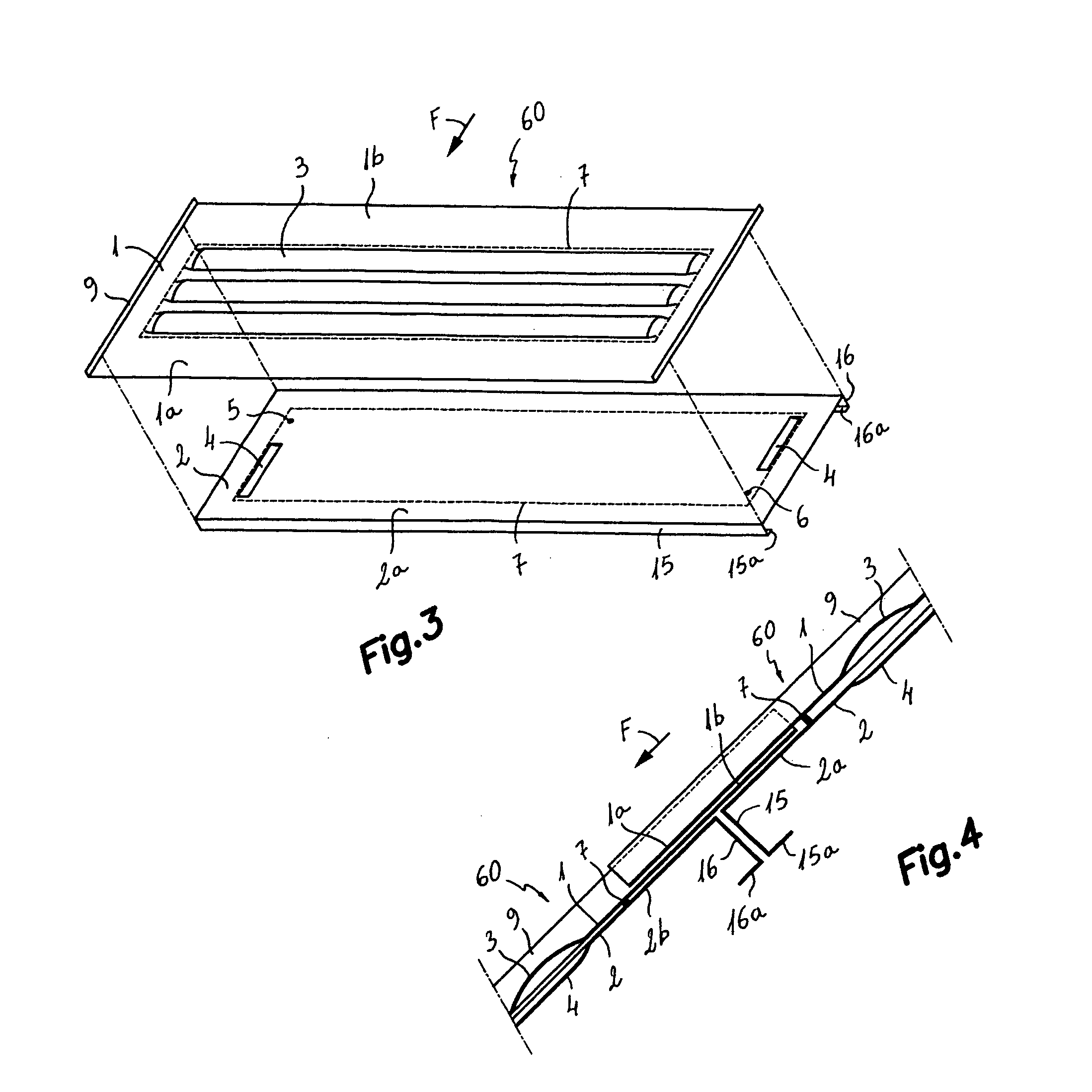

[0037] First referring to FIG. 1, reference numeral 50 generally refers to a modular solar energy-collecting enclosure element for buildings, applicable to both roofs and façades in accordance with an exemplary embodiment of the first aspect of this invention. The mentioned modular solar energy-collecting enclosure element 50, in its most elementary version, comprises an outer plate 1 and an inner plate 2, facing each other and joined together by at least one leak-tight joint line 7 along the length of a closed perimeter. In FIG. 1, the position of this leak-tight joint line 7, which can be obtained, for example, by a continuous roll welded bead, is shown as dotted lines 7 in relation to outer plate 1 and inner plate 2. In the shown exemplary embodiment, the outer plate 1 includes, within the perimeter defined by the leak-tight joint line 7 some conformations 3 that define three slightly concave channels on the inner side of the outer plate 1, which run parallel to the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com