Roof system

a roof system and roof plate technology, applied in the field of roof plate systems, can solve the problems affecting the performance of the roof plate, so as to improve the uplift strength, eliminate the problem of deterioration of the blocking assembly, and improve the fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

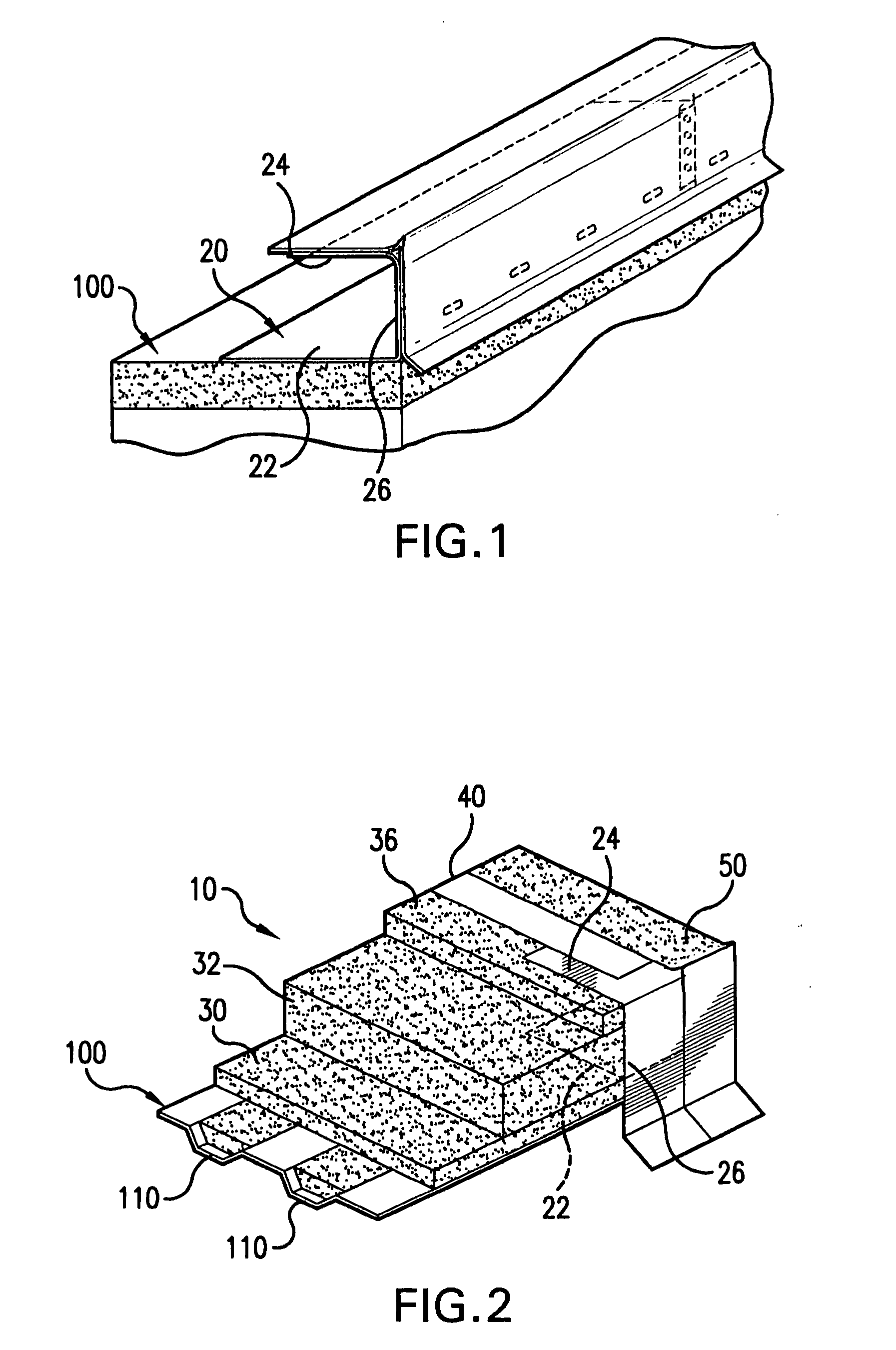

[0017]The roof system of the present invention is shown in FIG. 2 and is generally indicated as 10.

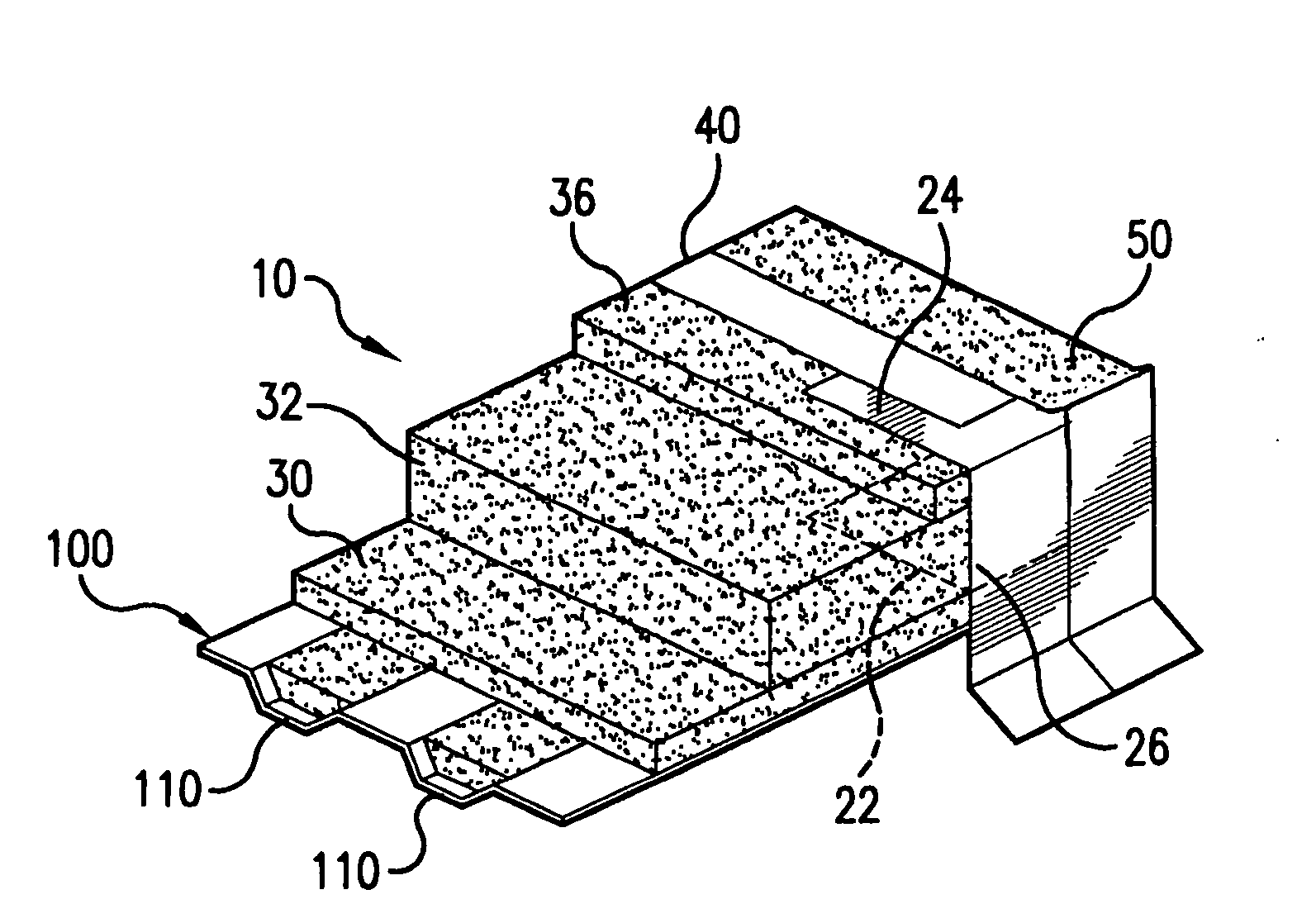

[0018]Referring to FIG. 1, a non-corrosive metal blocking structure is used in the roof system of the present invention and replaces wood blocking of conventional roof systems. In this particular embodiment, the non-corrosive metal blocking structure is a perimeter edge closure 20 that includes an anchoring flange 22 that attaches to the roof deck 100 using industry standards fasteners. The perimeter edge closure 20 also includes and upper flange 24 extending in spaced, parallel relation above the anchoring flange 22, forming a gap or area of depth therebetween. An intermediate flange 26 extends perpendicularly between the upper flange and the anchoring flange along the outer perimeter of the roof.

[0019]Referring now to FIG. 2, the entire assembled components of the roof system 10 are shown in a cross-sectional perspective view. In this particular example, the underlying roof deck 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com