Enclosed uplift pressure measuring structure

A pressure-raising and closed-type technology, which is applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of easy blockage, loss of downstream watershed, high production cost, etc., and achieves the effect of not easy to corrode, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

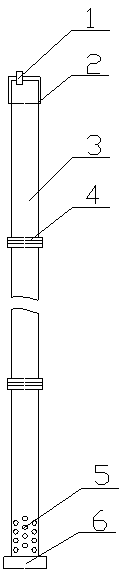

[0024] The closed uplift pressure measurement structure of the present invention is realized in the following way: the closed uplift pressure measurement structure of the present invention includes a measuring tube (3), a pressure transmitter (1) and a plug (2), and is characterized in that the measuring tube ( 3) It is a pipe that is sealed with plugs (2) at both ends and has a water permeable hole (5) on the pipe wall near the bottom. The pressure transmitter (1) is installed on the measuring pipe (3) On the plug (2) at the top of the pressure transmitter (1), the sensing unit of the pressure transmitter (1) goes deep into the measuring tube (3);

[0025] The hollow pipe is made of PVC pipe;

[0026] Further, a gravity mounting plate (6) is installed on the bottom of the measuring tube (3), the gravity mounting plate (6) is made of cast iron, and the outer surface is provided with an anti-corrosion coating; the gravity mounting plate (6) ) at the edge, uniformly threaded ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com