Floor mold type composite bottom board structure

A base plate and pattern technology, applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of high project cost, large amount of steel bars, and long construction period, so as to save steel consumption and reduce steel consumption Quantity, reduce the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

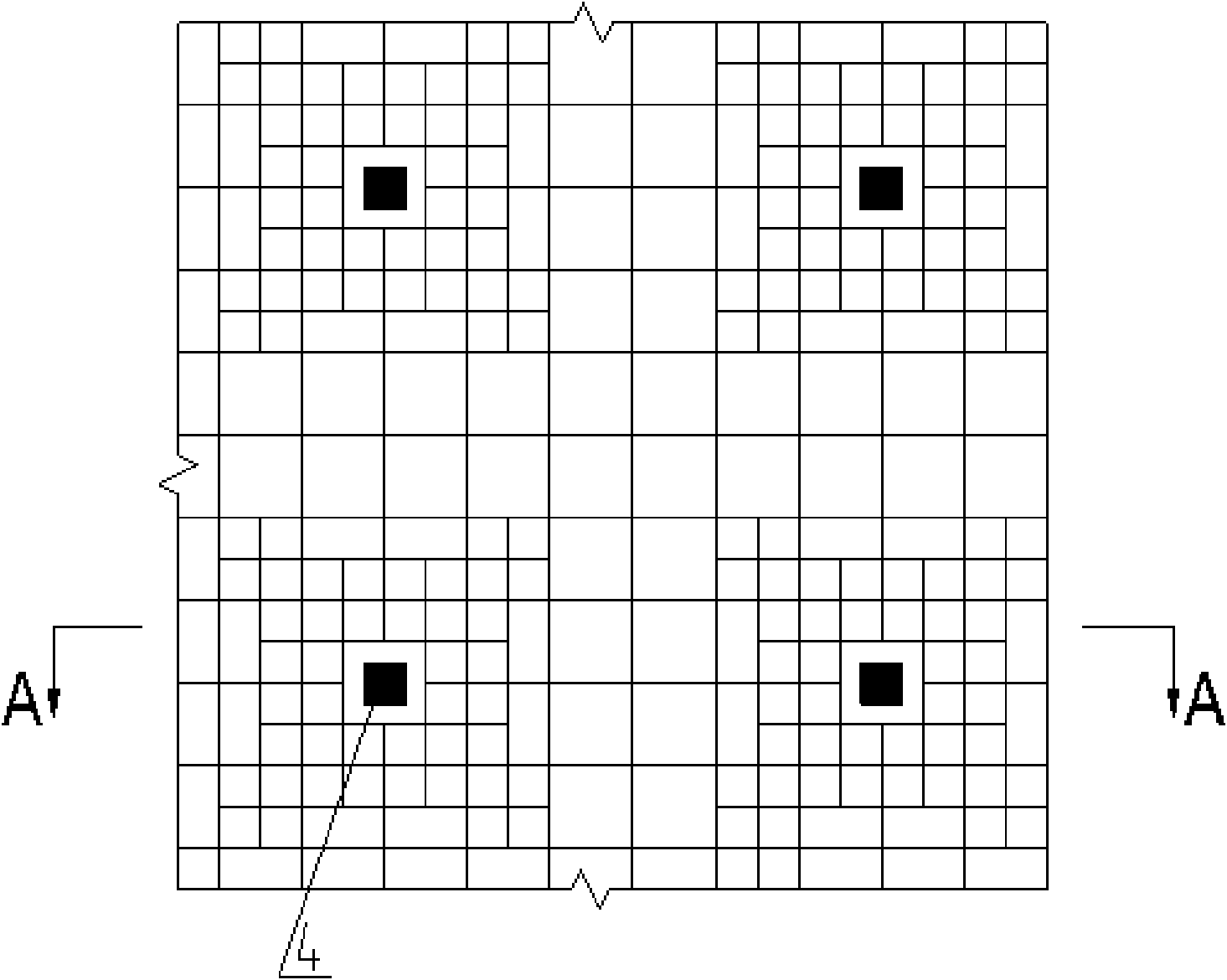

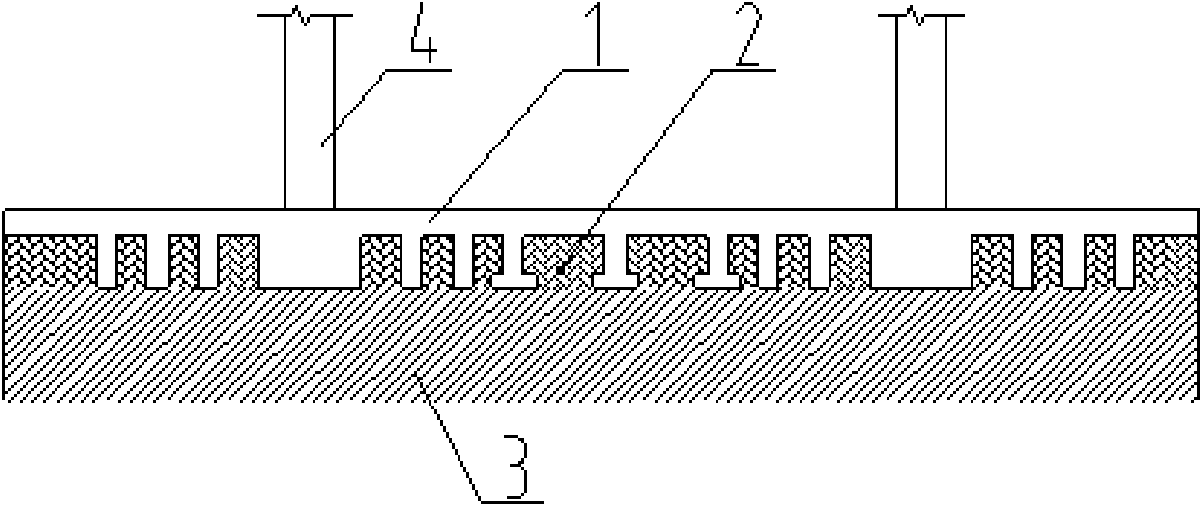

[0017] Embodiments of the present invention: First, design the dense rib shape, spacing and cross-sectional size of the concrete dense rib slab structure 1 according to objective conditions such as soil quality, construction conditions and design requirements, and different dense rib spacing or rib width can be used in different plates and flange width, or section form. In the position of the greatest stress, such as the plate under the column and the support plate, the distance between the dense ribs can be doubled or the width of the dense ribs can be doubled. Concrete densely ribbed structure 1 adopts variable rib spacing, variable rib width and flange width, and variable cross-section structure, and can also adopt different dense rib spacing or rib width and flange width, or cross-sectional forms on the same plate. If the force in one direction of the inter-column plates is large and the force in the other direction is small, the spacing of the ribs in the direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com