Rolling, sliding part and process for producing same

a technology of rolling and sliding parts, applied in the direction of solid-state diffusion coatings, mechanical devices, coatings, etc., can solve the problems of low material cost and consequently low overall manufacturing cost, and achieve the effects of reducing material cost, preventing fatigue cracking, and ensuring toughness

Inactive Publication Date: 2007-10-18

JTEKT CORP

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The present invention provides a rolling, sliding part that is improved in wear resistance, usable with a lubricant free of or less susceptible to extraneous matter, and less susceptible to compressive stress. The part is made of bearing steel, which is a low-cost material, and can be produced using a carburizing treatment. The part is suitable for use in antifriction bearings of prolonged life. The invention also provides a process for producing the rolling, sliding part, which involves heating the part in a carburizing atmosphere, quenching it, and optionally carburizing it again to form a surface layer with improved properties. The use of a bearing steel that is available by mass production reduces the material cost.

Problems solved by technology

The part is made of bearing steels (High carbon chromium bearing steels) which are produced in large quantities, accordingly low in material cost and consequently low in overall manufacturing cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

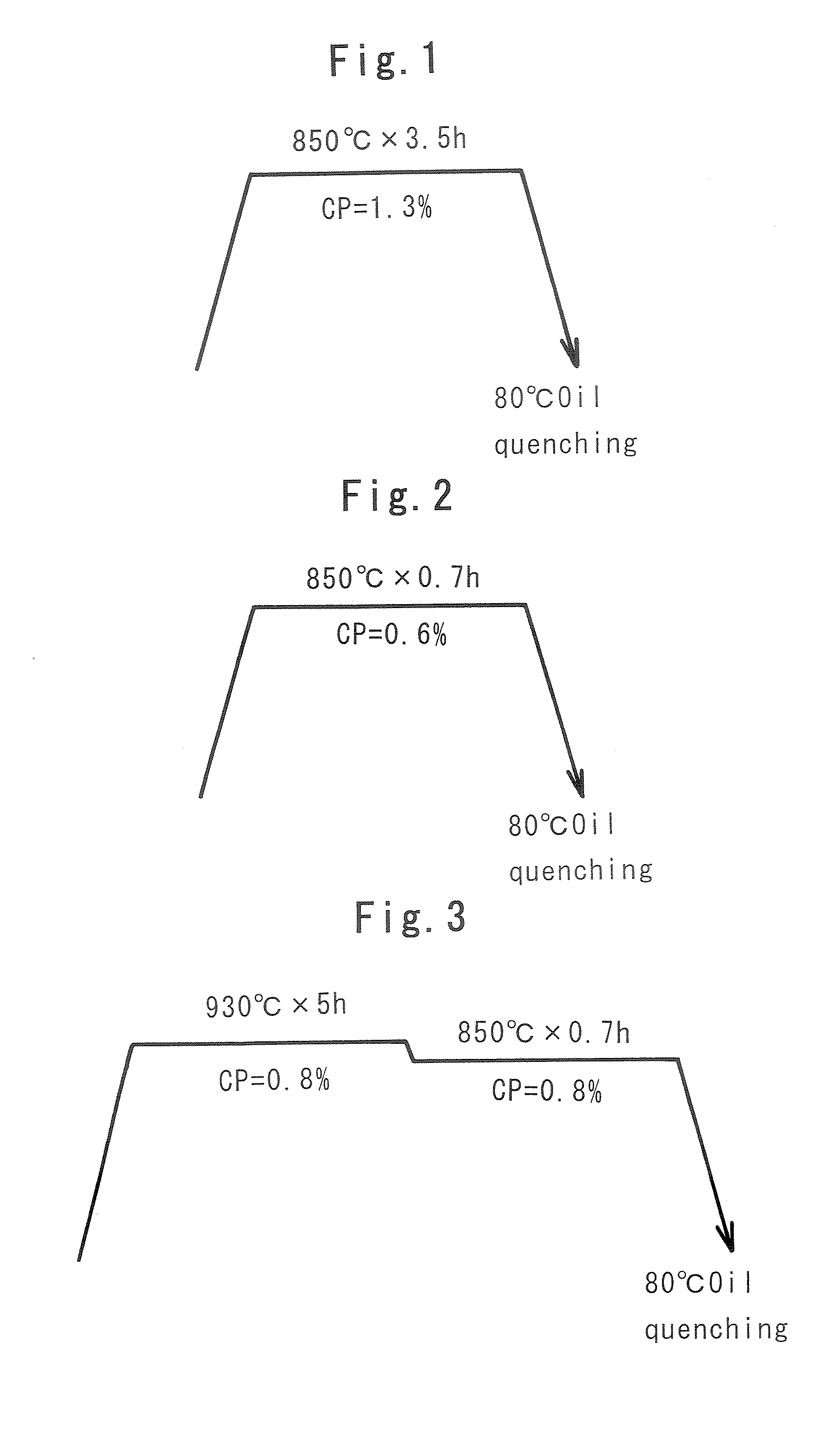

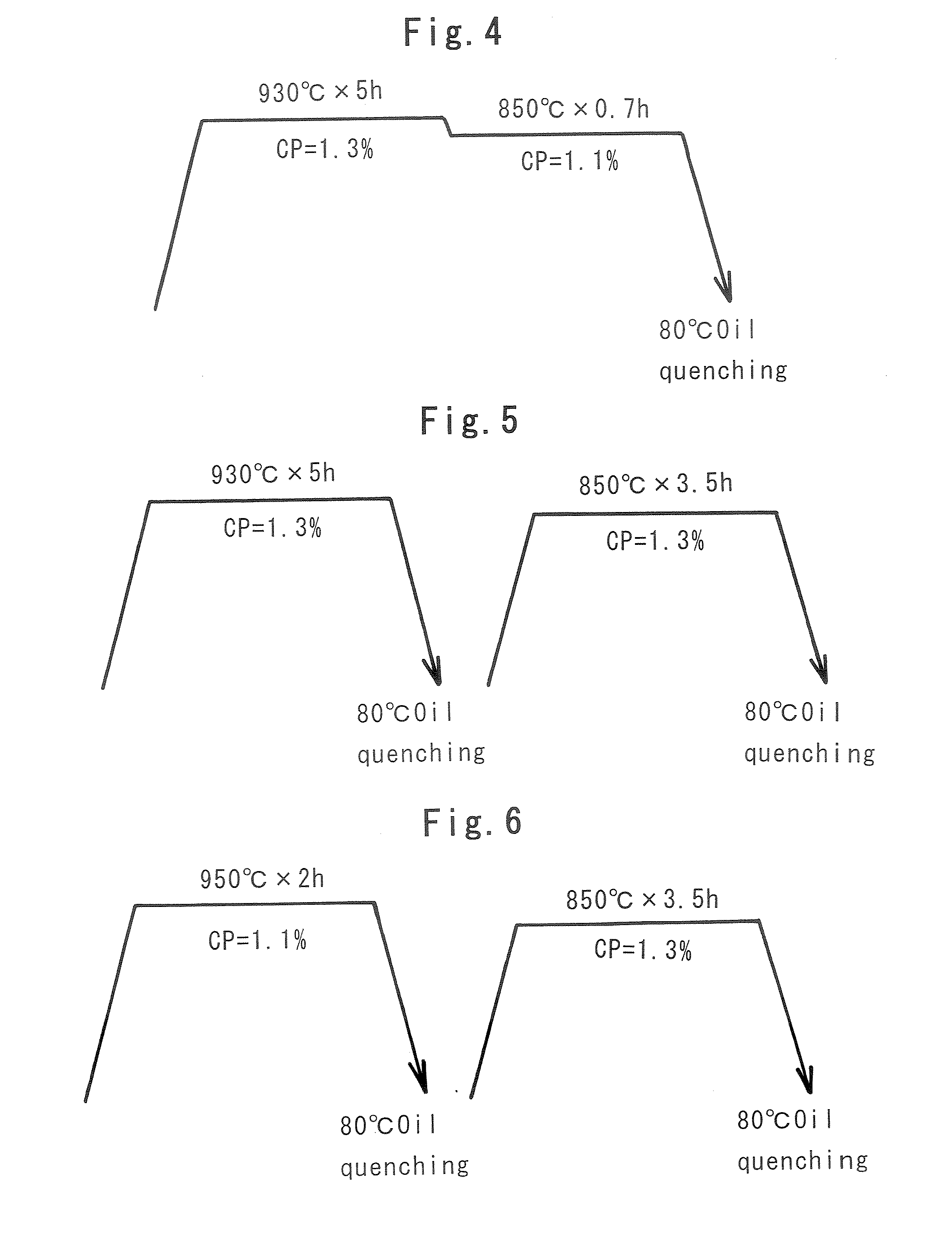

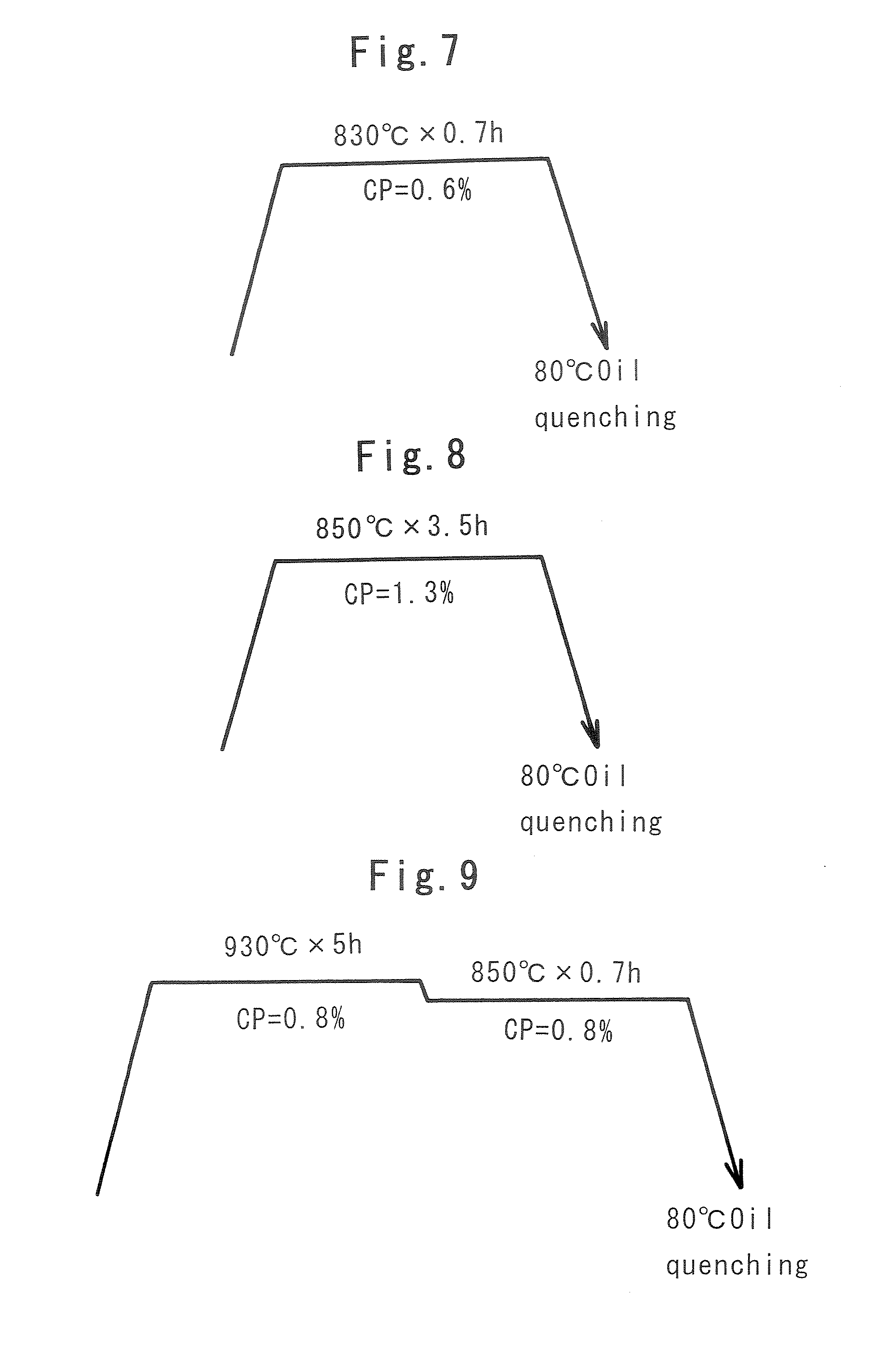

[0053] Specific examples of the invention are given below along with comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Login to View More

Abstract

A rolling, sliding part comprises a bearing steel, is subjected to a carburizing treatment and has a surface layer from a surface the part to a depth to which a maximum shear stress acts. The surface layer is 1.0 to 1.6 wt. % in total carbon content, has a matrix containing 0.6 to 1.0 wt. % of solid-solution carbon, and contains a precipitating carbide in an amount of 5 to 20% in area ratio, the carbide being up to 3 μm in particle size. The rolling or sliding part is improved in wear resistance, usable with a lubricant free of or less susceptible to impression by extraneous matter present in the lubricant, and less susceptible to compressive stress due to the extraneous matter, with the development of cracks suppressed.

Description

BACKGROUND OF THE INVENTION [0001] The present invention relates to rolling, sliding parts and a process for producing the same, and more particularly to races of antifriction bearings and rolling parts for use as rolling elements of such bearings, or sliding parts suitable for use in sliding bearings, as adapted for use with a lubricant containing extraneous matter, and to a process for producing such parts. [0002] To give a prolonged life to antifriction bearings for use with a lubricant containing extraneous matter becoming mixed therewith, it is required to increase the surface hardness of the races and rolling elements of the bearing, for example, to 62 to 67 in Rockwell C hardness (hereinafter referred to as “HRC”), to precipitate a predetermined amount of fine carbide as dispersed in the surface layers of the raceway surfaces and the rolling surfaces of the rolling elements, to adjust the amount of retained austenite in the surface layers of the raceway surfaces and the rolli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C23C8/00C23C8/22C23C8/80

CPCC23C8/80C23C8/22F16C33/32F16C33/62

Inventor KIZAWA, KATSUHIKO

Owner JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com