Light emitting diode package and fabrication method thereof

a technology of light-emitting diodes and fabrication methods, which is applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of increasing manufacturing time and cost, low heat radiation efficiency, and complicated conventional heat radiation structure, and achieves superior heat radiation efficiency and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

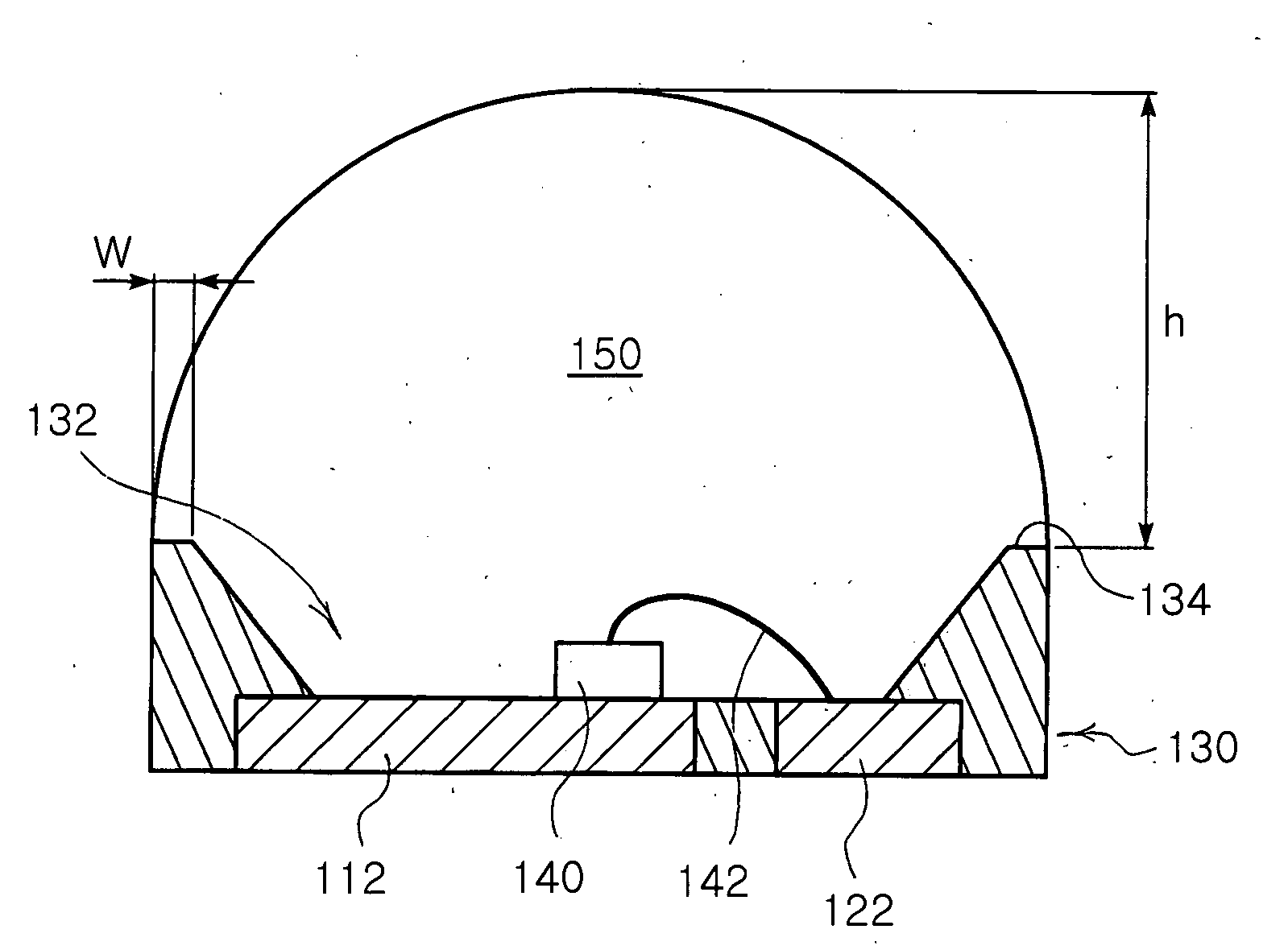

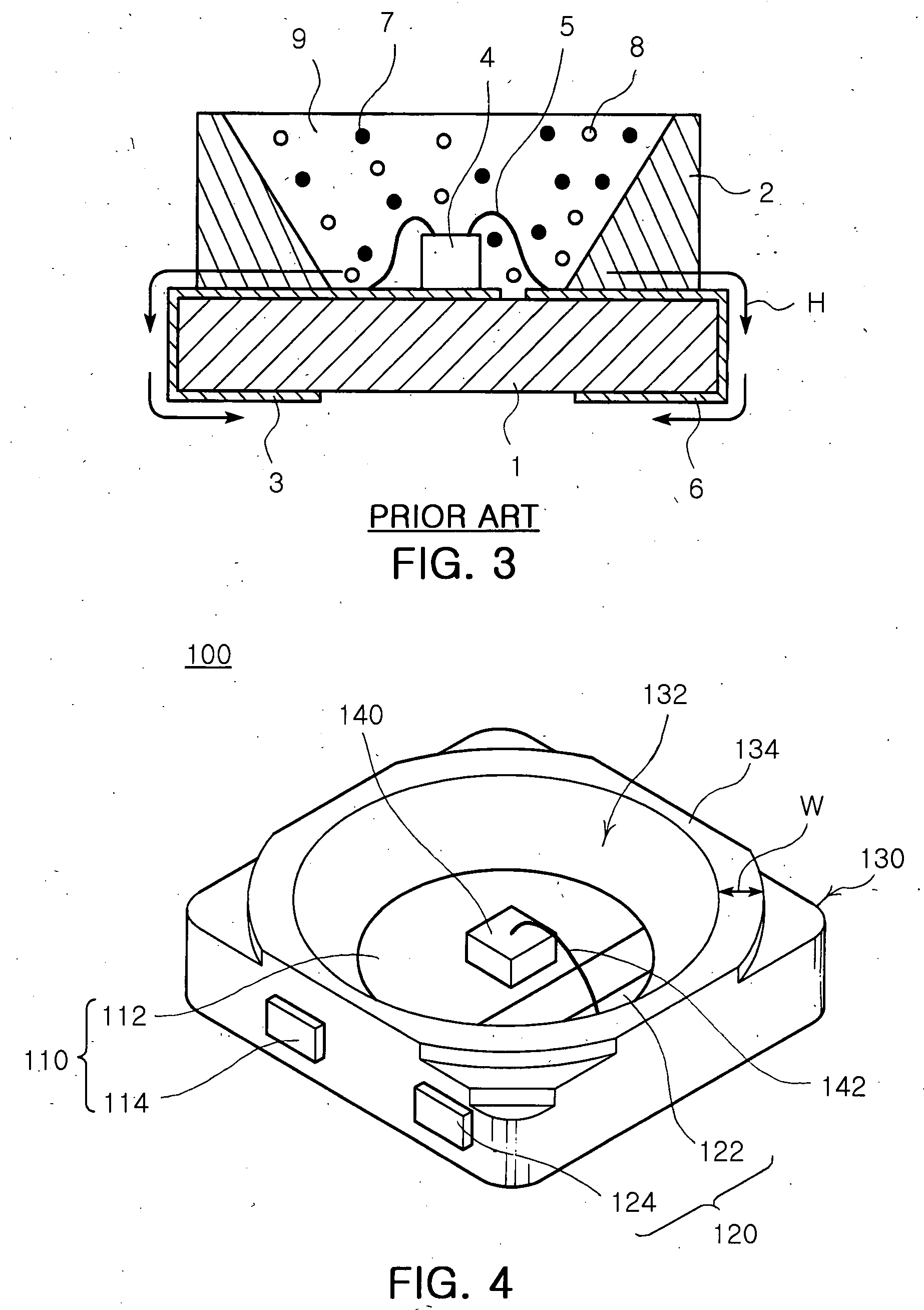

[0052]An LED package according to a first embodiment of the present invention is illustrated in FIGS. 4 to 8.

[0053]The LED package 100 according to this embodiment includes a pair of metal lead frames 110 and 120 and an insular package body 130 surrounding the lead frames 110 and 120.

[0054]The first lead frame 110 includes a planar base 112 and a pair of extensions 114 extending from opposed ends of the base 112. It is preferable that the base 112 is provided in an area as large as possible so that it has a large contact area as possible with a circuit board (see FIG. 10) described later, which is a heat sink. The extensions 114 are formed in a smaller width than the base 112, and are surrounded by the package body 130 to secure the lead frame 110 to the package body 130. Of course, the extensions 114 can be formed in the same width as the base 112, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com