Camera track and dolly system

a dolly system and camera technology, applied in the direction of machine supports, railway auxiliaries, locomotives, etc., can solve the problems of difficult use of rack and pinion arrangements with curved tracks, less accurate repetition of camera movements, and restricted track curves. achieve the effect of accurate and repeatable positioning of the dolly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

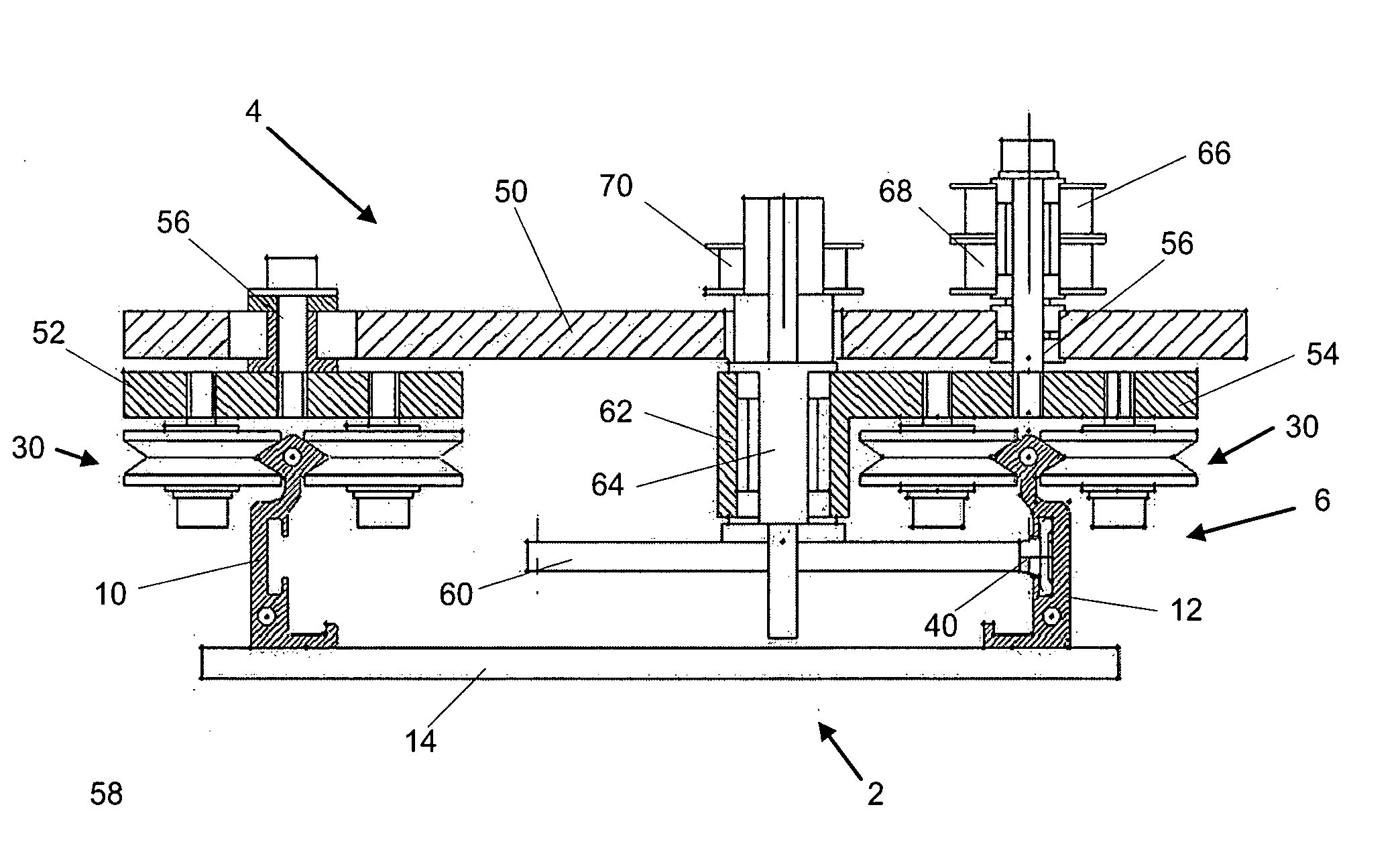

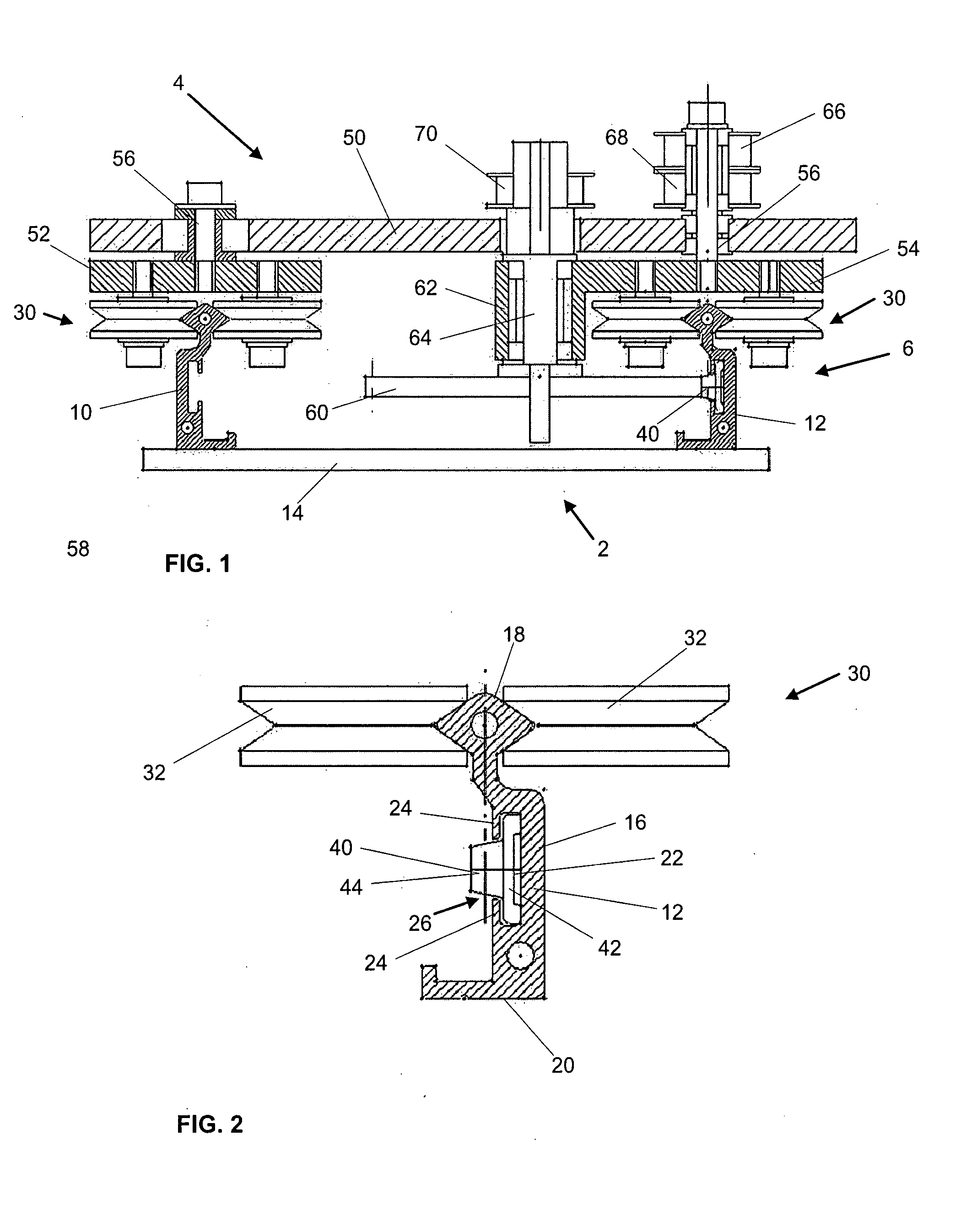

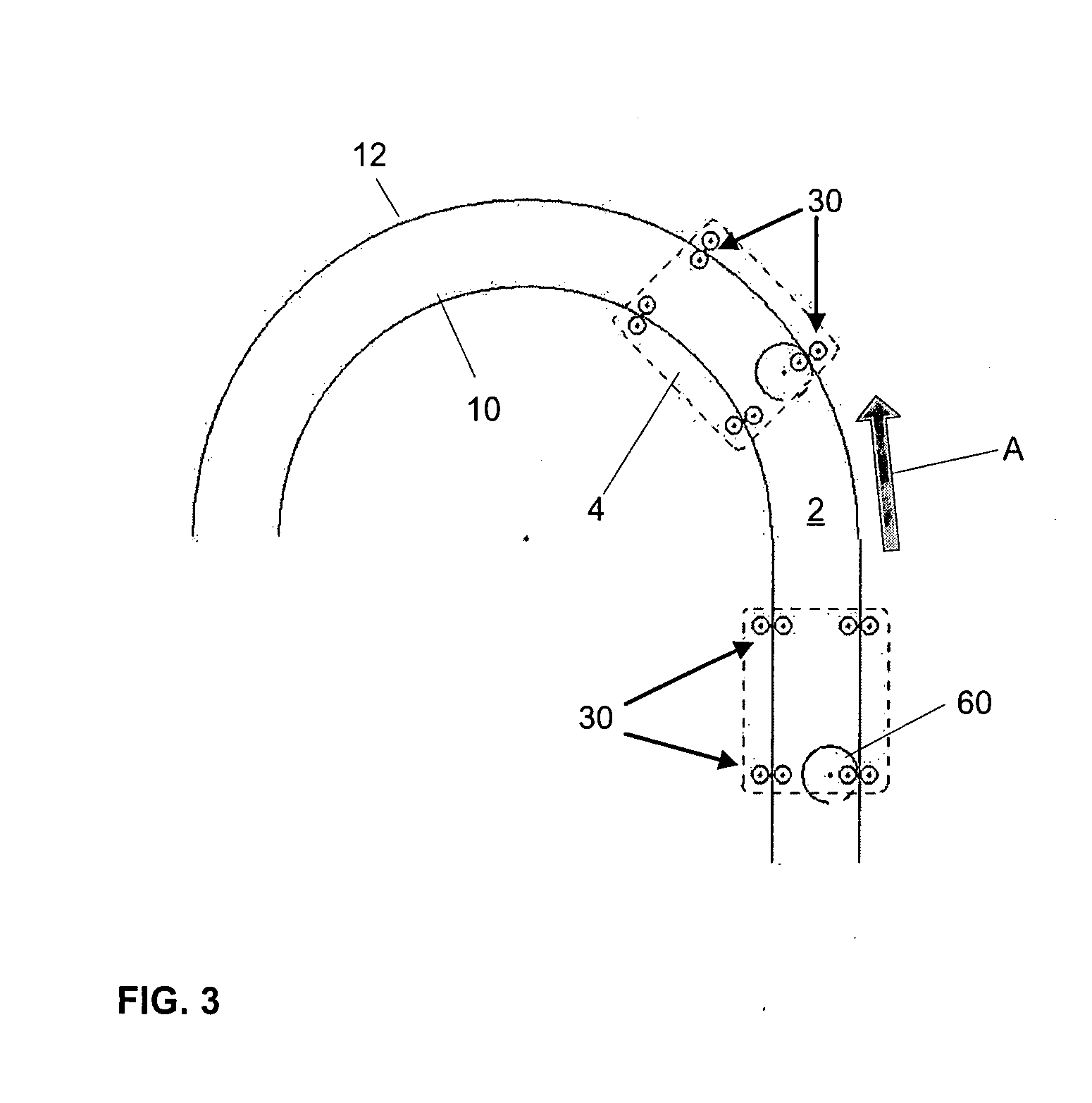

[0043]The figures illustrate a presently preferred embodiment of the camera dolly and track system of the present invention. In overview, the system includes a track 2 and a dolly (carriage) 4 that rides on the track 2. A camera (not shown) can be mounted on the upper side of the dolly 4, for example on a remote control head (also not shown). The dolly 4 is driven along the track 2 by a rack and pinion drive mechanism, indicated generally at 6.

[0044]The track can include straight and curved sections (see FIG. 3) and the dolly drive mechanism 6 is configured in the manner described below to ensure that it operates to accurately and repeatedly move the dolly 4 (and hence the camera mounted on it) along the track 2 on curved as well as straight sections of the track and at transitions between curved and straight sections. This ability to use rack and pinion type drives with curved dolly tracks offers significant advantages of the prior art curved systems using friction drives and winch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com