Material handling assembly

a technology for material handling and assembly, which is applied in the direction of mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of increasing the cost of manufacture and installation, requiring a certain amount of manual labor for fixing, and comparatively expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

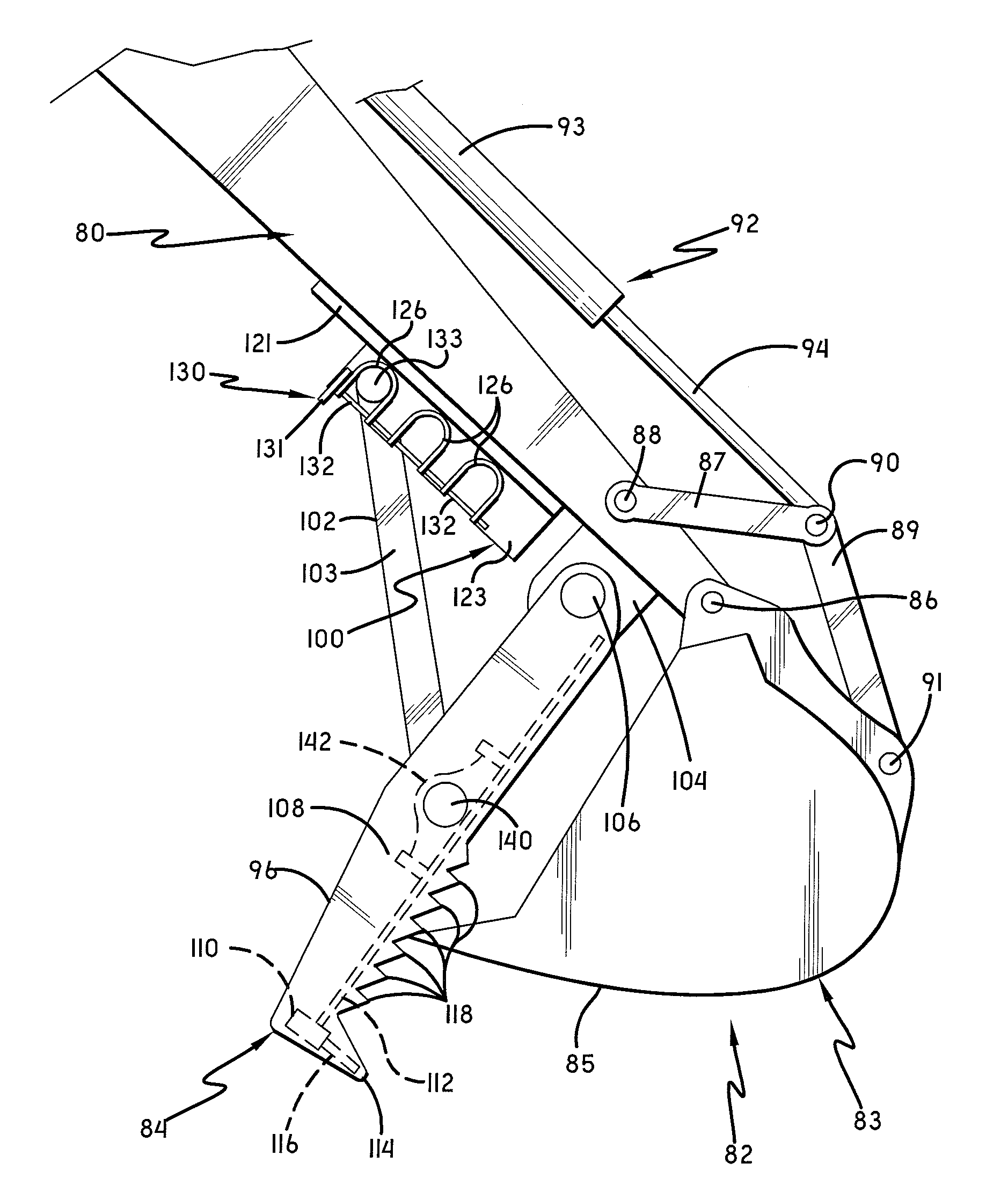

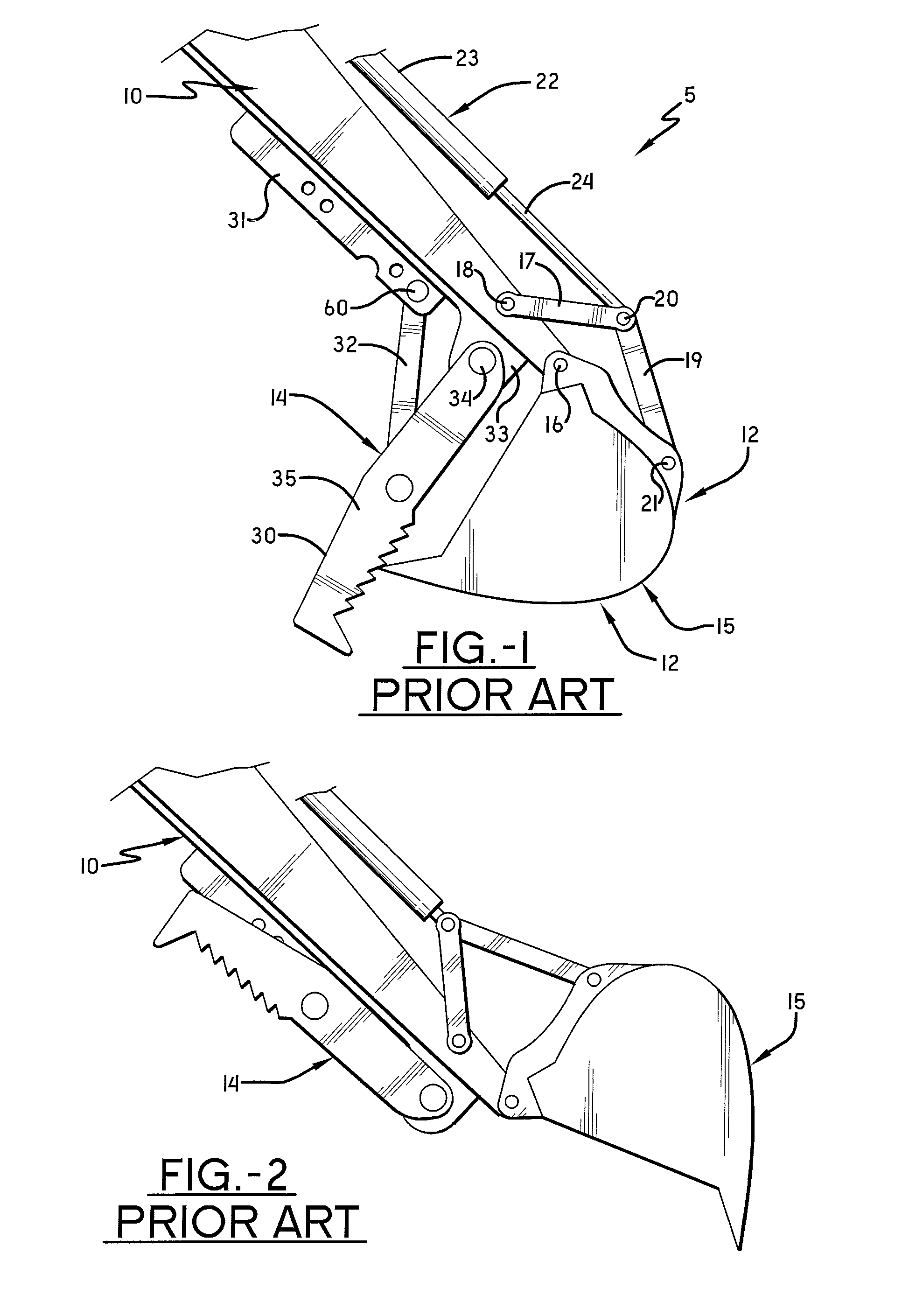

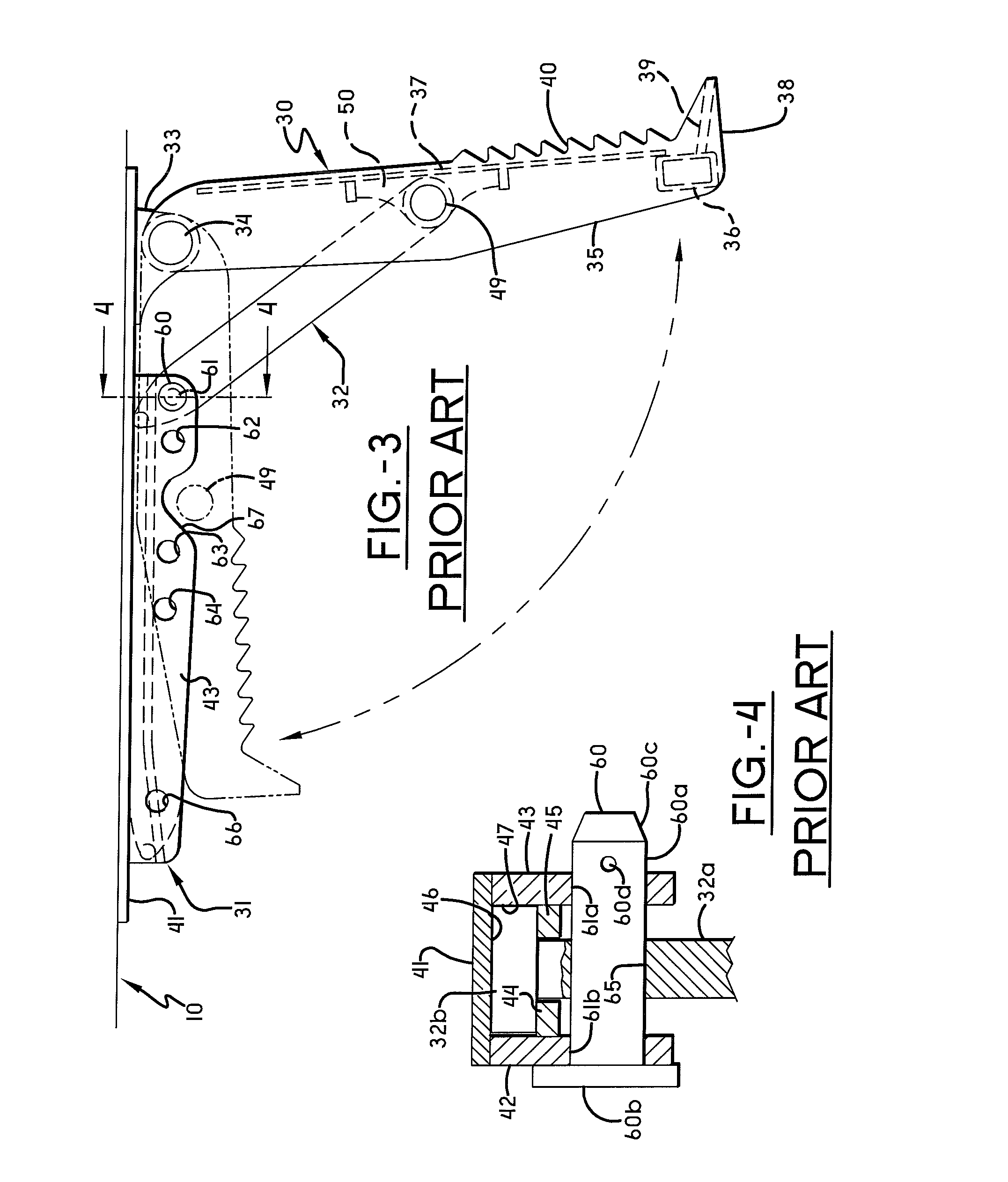

[0029]Referring now to the drawings wherein the showings are for purposes of illustrating various embodiments of the invention only and not for purposes of limiting the same, the figures illustrate the novel idea of a material handling assembly. The material handling assembly is an assembly mountable on the articulated arm of the machine consisting generally of a bucket pivotally connectable to the articulated arm of the machine and the means for pivoting the bucket about the pivotal connection of the bucket to the articulated arm, an arm member pivotally connectable to the articulated arm and cooperable with the bucket when mounted on the articulated arm for clamping material being handled therebetween, a bracket mountable on the underside of the articulated arm, having a guideway therealong, a strut having a first end thereof pivotally connected to the arm member and second end thereof received within and displaceable along the guideway, and means for detachably securing the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com