Method for Reducing Acrylamide Formation in Thermally Processed Foods

a technology of thermal processing and acrylamide, which is applied in the field of reducing the amount of acrylamide in thermal processing foods, can solve the problems of unconfirmed results, difficult to confirm findings, and undesirable effects, so as to and reduce the formation of acrylamid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

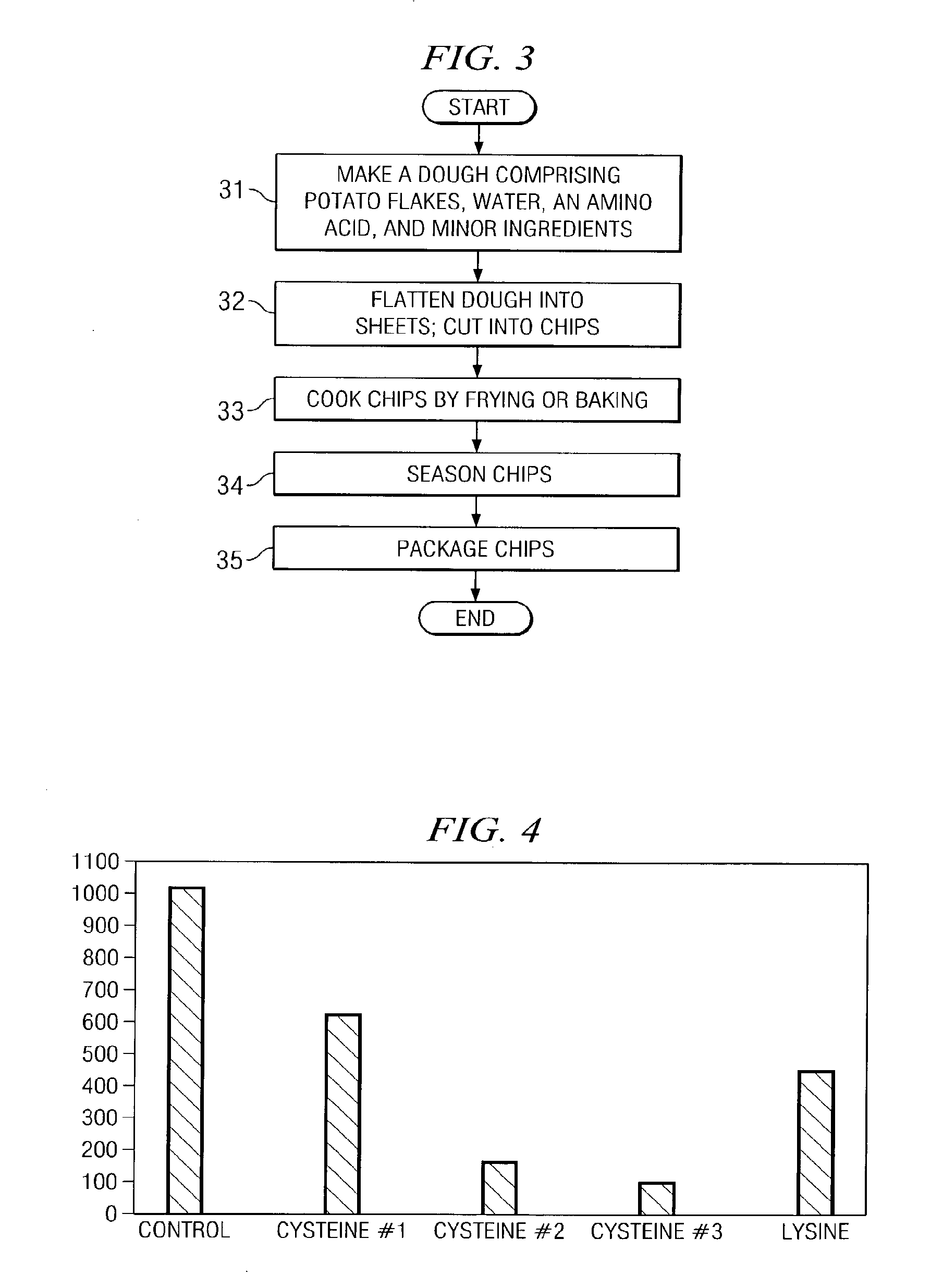

Effect of Amino Acids on Acrylamide Formation

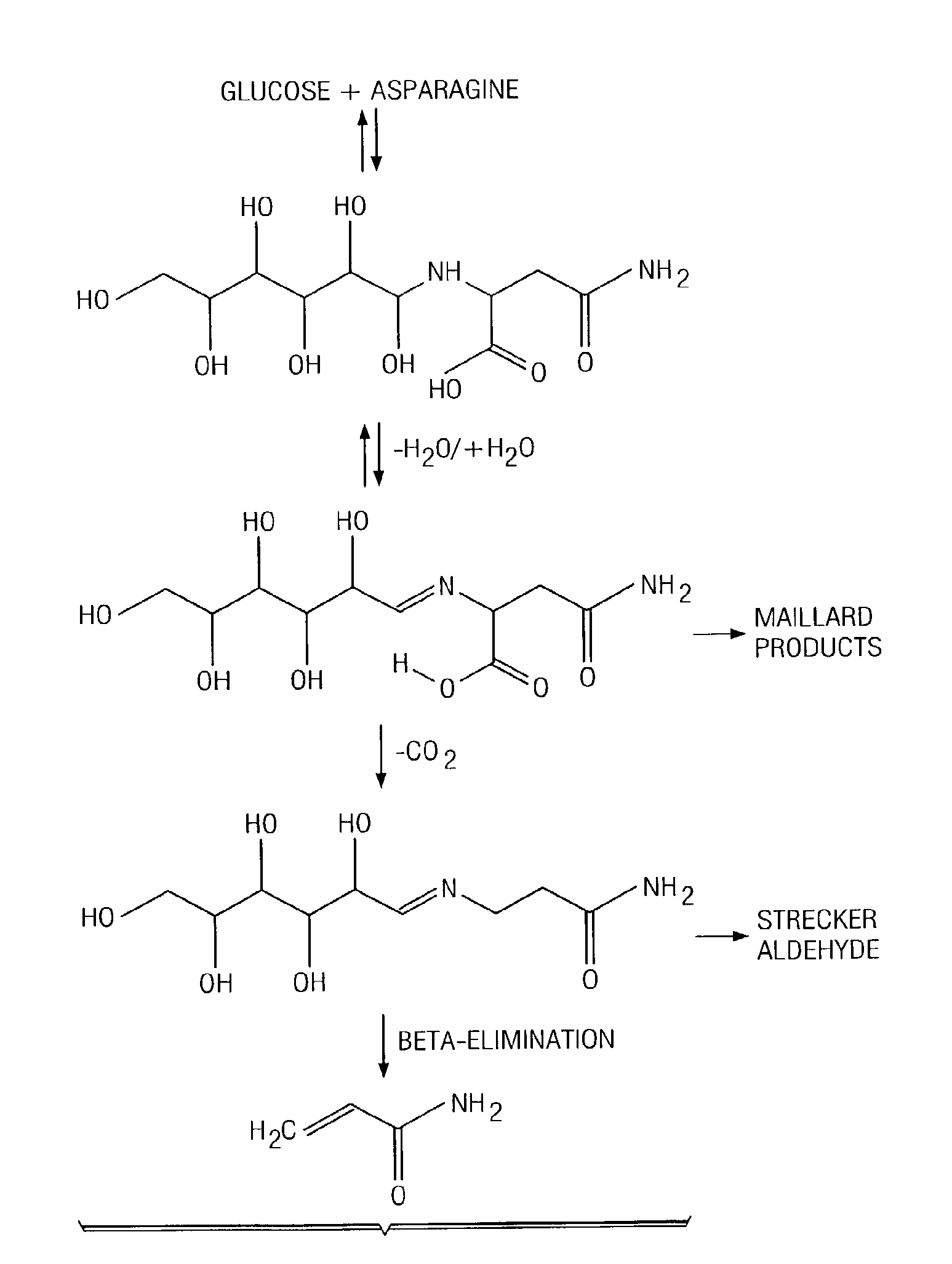

[0023] The formation of acrylamide in thermally processed foods requires a source of carbon and a source of nitrogen. It is hypothesized that carbon is provided by a carbohydrate source and nitrogen is provided by a protein source or amino acid source. Many plant-derived food ingredients such as rice, wheat, corn, barley, soy, potato and oats contain asparagine and are primarily carbohydrates having minor amino acid components. Typically, such food ingredients have a small amino acid pool, which contains other amino acids in addition to asparagine.

[0024] By “thermally processed” is meant food or food ingredients wherein components of the food, such as a mixture of food ingredients, are heated at temperatures of at least 80° C. Preferably the thermal processing of the food or food ingredients takes place at temperatures between about 100° C. and 205° C. The food ingredient may be separately processed at elevated temperature prior to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com