Compound for forming wiring conductor, fabrication method of circuit board using the same and circuit board

a technology of wiring conductor and compound, which is applied in the direction of resistive material coating, metallic pattern materials, non-conductive materials with dispersed conductive materials, etc., can solve the problems of inability to obtain desired patterns, inability to obtain ink discharge ports, and inability to achieve desired patterns, etc., to achieve the effect of reducing resistivity, improving strength as a conductor, and forming sure and inexpensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0068] First of all, in embodiment 1, a compound (and a composition thereof) for forming wiring conductor, one of the technologies proposed by the present invention, will be described.

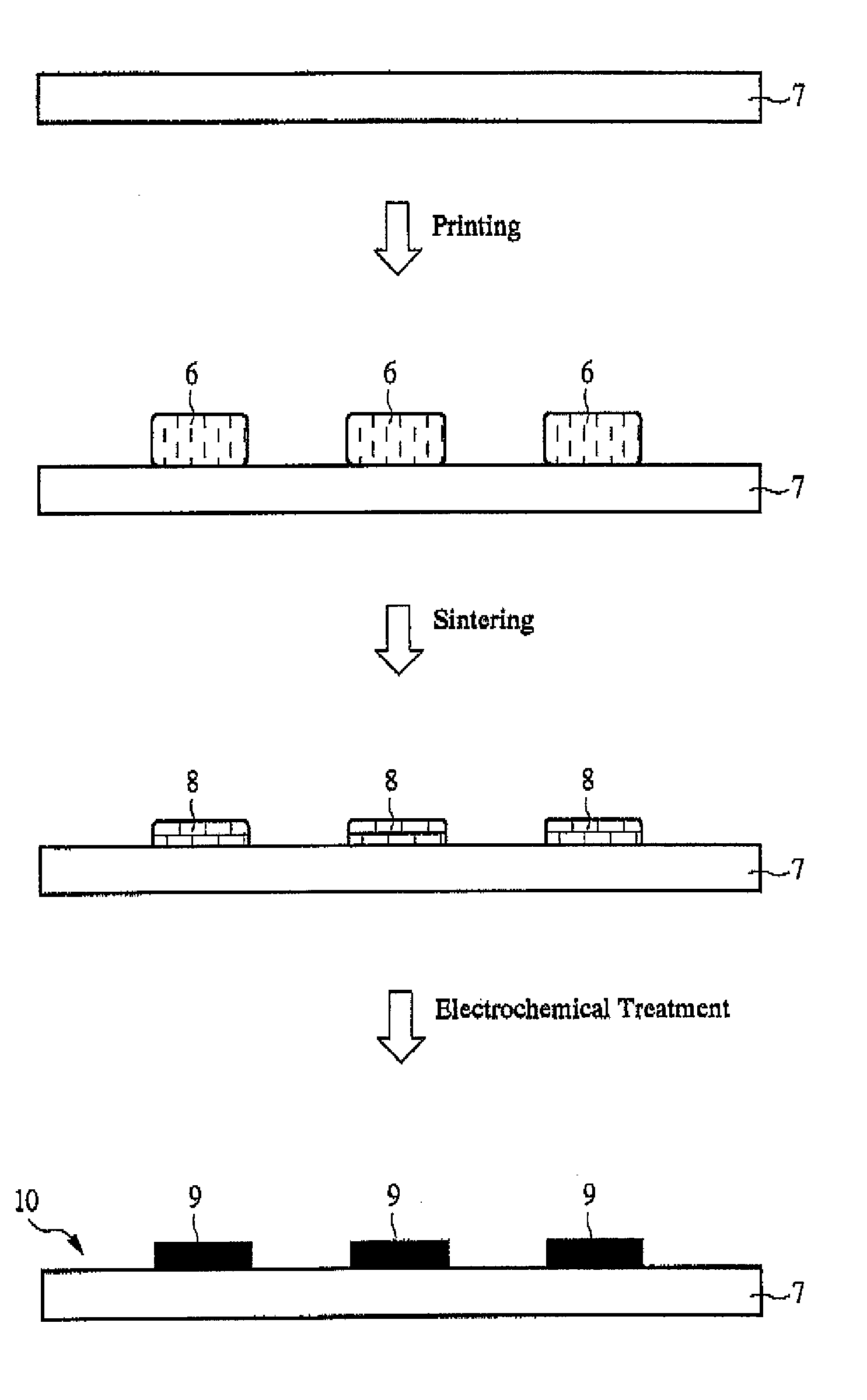

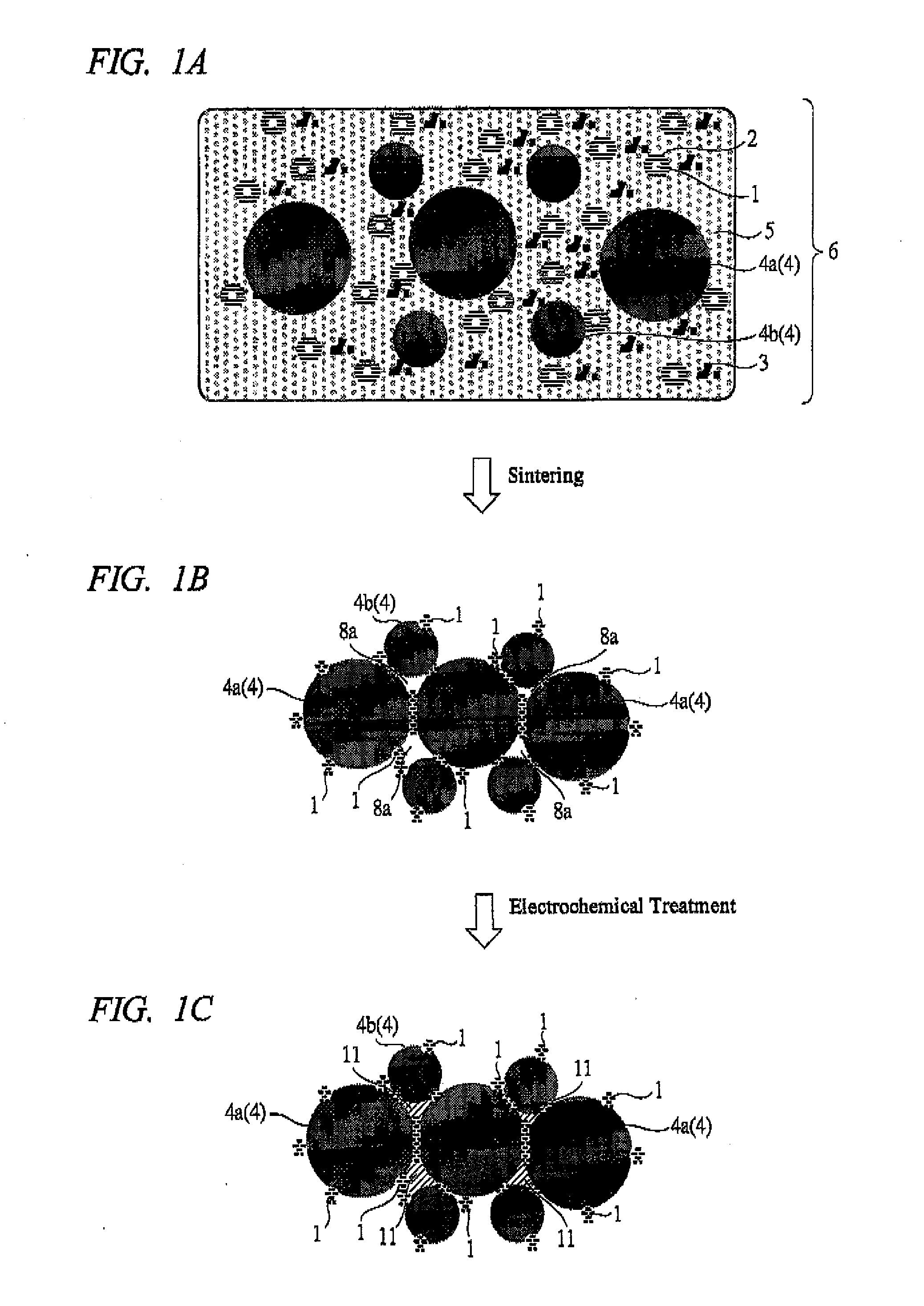

[0069] As shown in FIG. 1A, compound for forming wiring conductor 6 related to the present invention contains:

[0070] (a) superfine metal particles (metal nanoparticles) 1 whose average particle size is 1 through 10 nm;

[0071] (b) an organic coating compound 2 coated on the surface of the superfine metal particle 1 in the film thickness of 1 through 10 nm;

[0072] (c) a latent reactive organic compound 3 that reacts with the organic coating compound in the range from 100 to 250° C.;

[0073] (d) metal particles 4 whose average particle size is 0.5 through 10 μm; and

[0074] (e) dispersion medium 5 that stably disperses components (a) through (d).

[0075] The superfine metal particles 1 suited for the present invention are so-called metal nanoparticles of average particle size between 1 and 10 nm. For this ...

embodiment 2

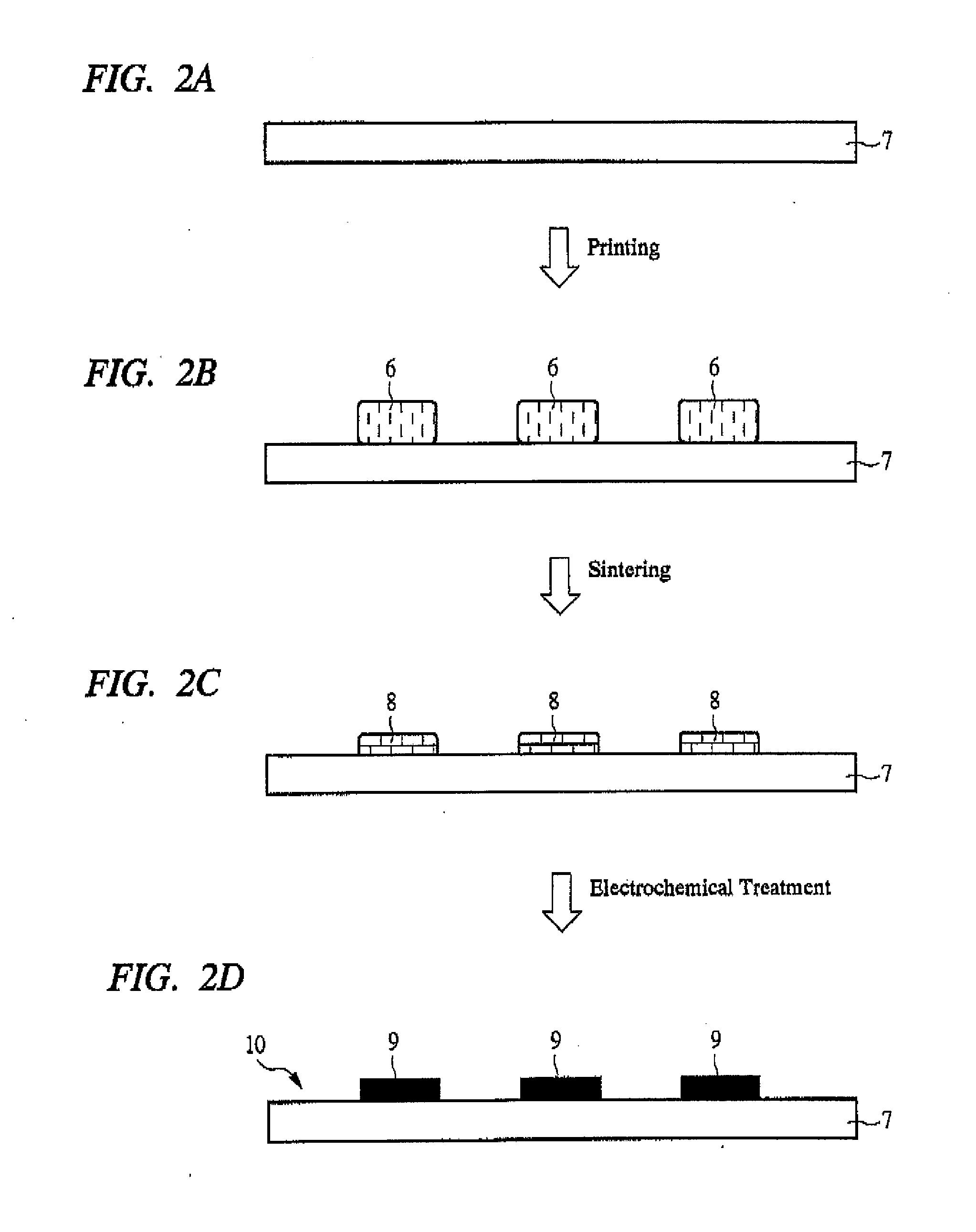

[0106] In the embodiment 2, a circuit board for which the wiring conductor fabricated by the use of the compound for forming wiring conductor related to the present invention described in the embodiment 1 is used and the wiring conductor is at least partially used and fabrication method thereof will be described.

[0107] By using the compound for forming wiring conductor 6 proposed by the present invention, the wiring conductor can be conveniently formed, and by using this wiring conductor at least for part of it, a circuit board can be fabricated at low cost and in a short time.

[0108]FIG. 2A shows a substrate 7 that serves as a base of the circuit board. As shown in FIG. 2B, on the surface of the substrate 7, the compound for forming wiring conductor 6 is formed into film to have a desired pattern shape. Thereafter, as shown in FIG. 2C, by heating treatment the substrate in such a manner that the pattern portion is sintered, a wiring conductor 8 with the desired pattern can be obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com