Implant

a technology of implants and implants, applied in the field of implants, can solve problems such as fractures in bone tissue, and achieve the effect of increasing the stiffness of implants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

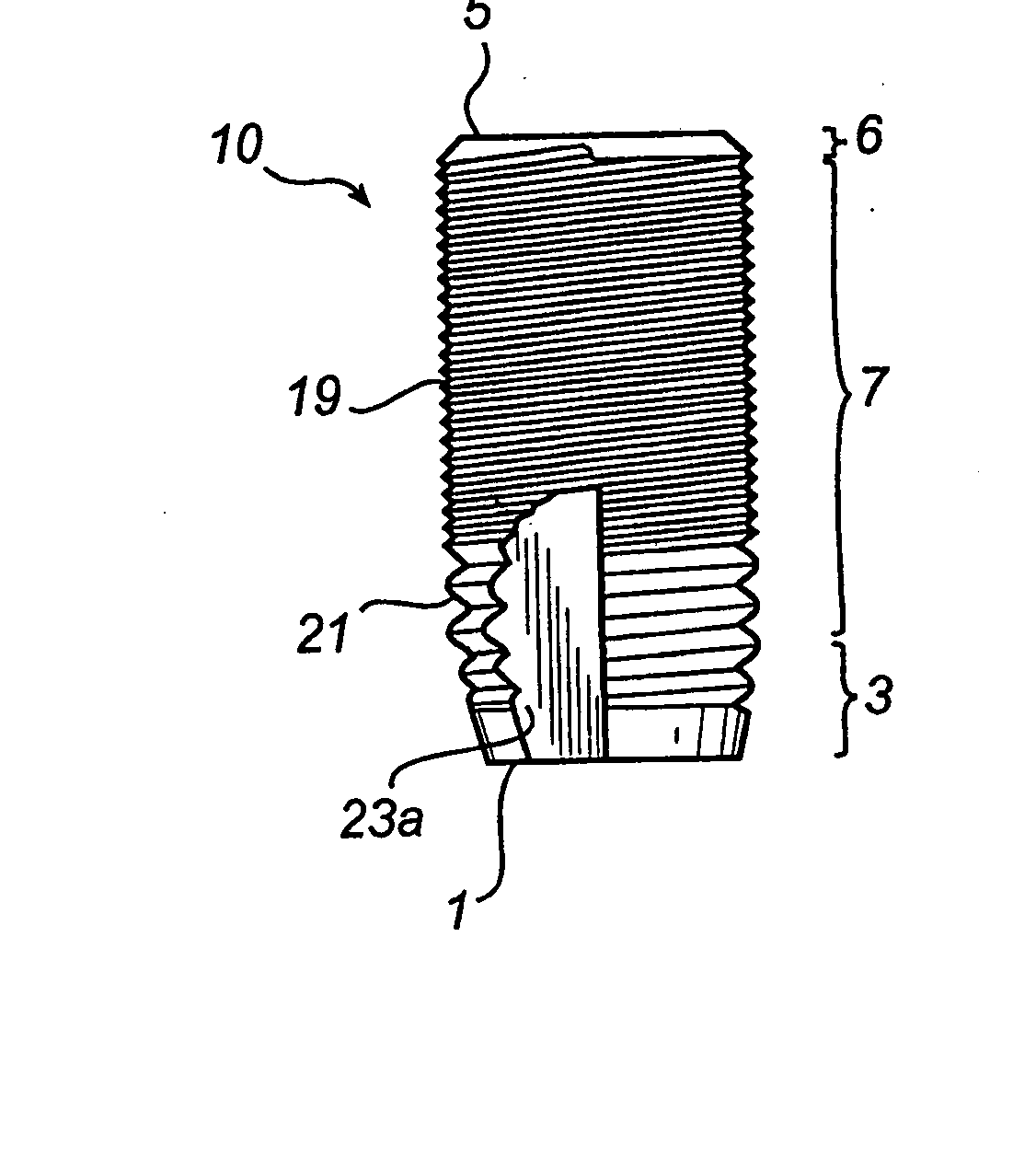

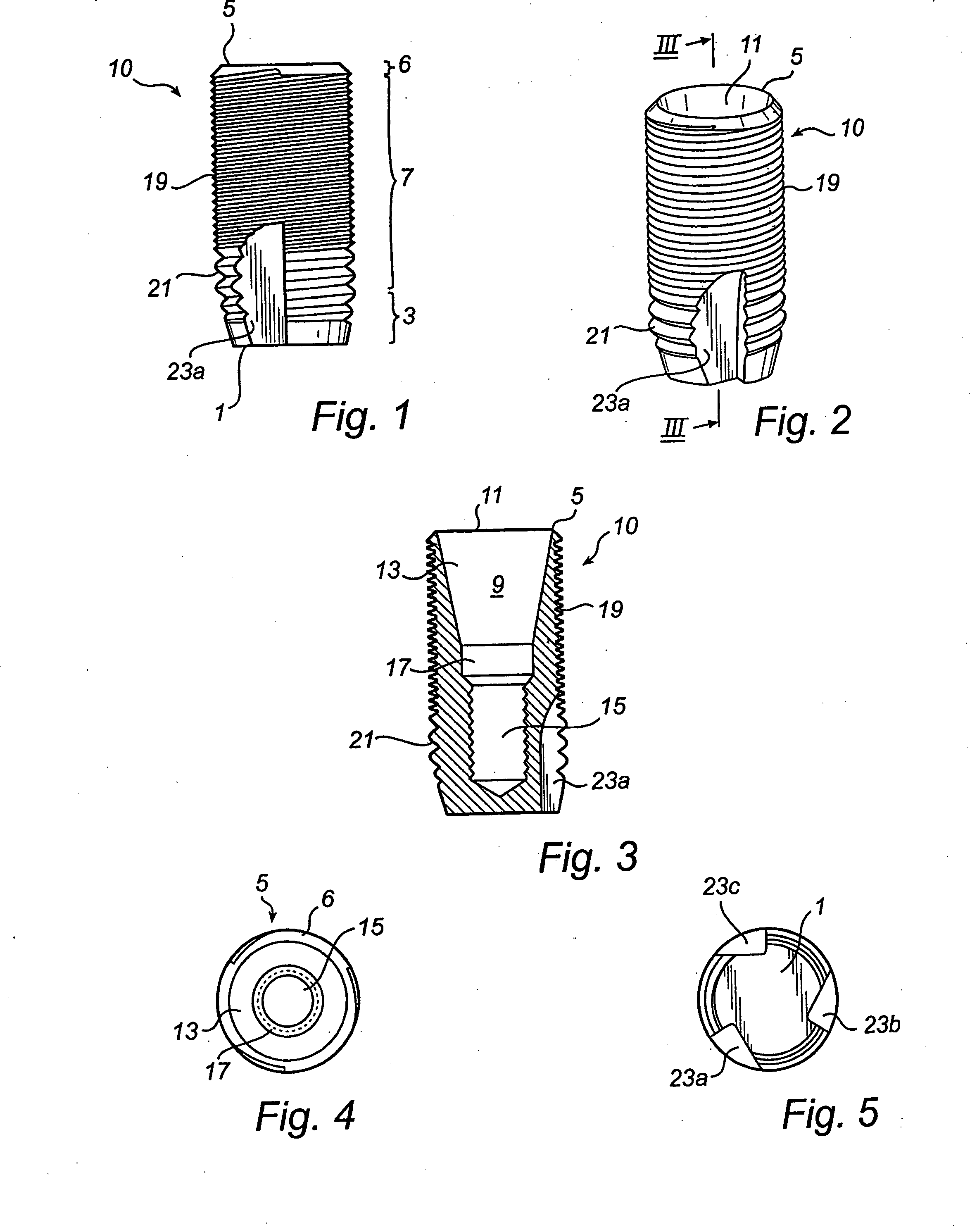

[0041] In the accompanying Figures of drawings there is shown various views of a self-tapping endosseous screw-type dental implant 10 of a dental prosthesis in accordance with the present invention. The implant 10 is for insertion into a bore-hole drilled into a toothless-site in a maxilla or mandible of a partially or fully edentulous patient to anchor to the maxilla or mandible a superstructure of the prosthesis which comprises a prosthetic part, namely one or more artificial teeth. The implant 10 is made from commercially pure titanium, a titanium alloy, another biocompatible metal or metal alloy or a ceramic to promote osseointegration of the implant with the bone tissue of the boundary walls of the bore-hole.

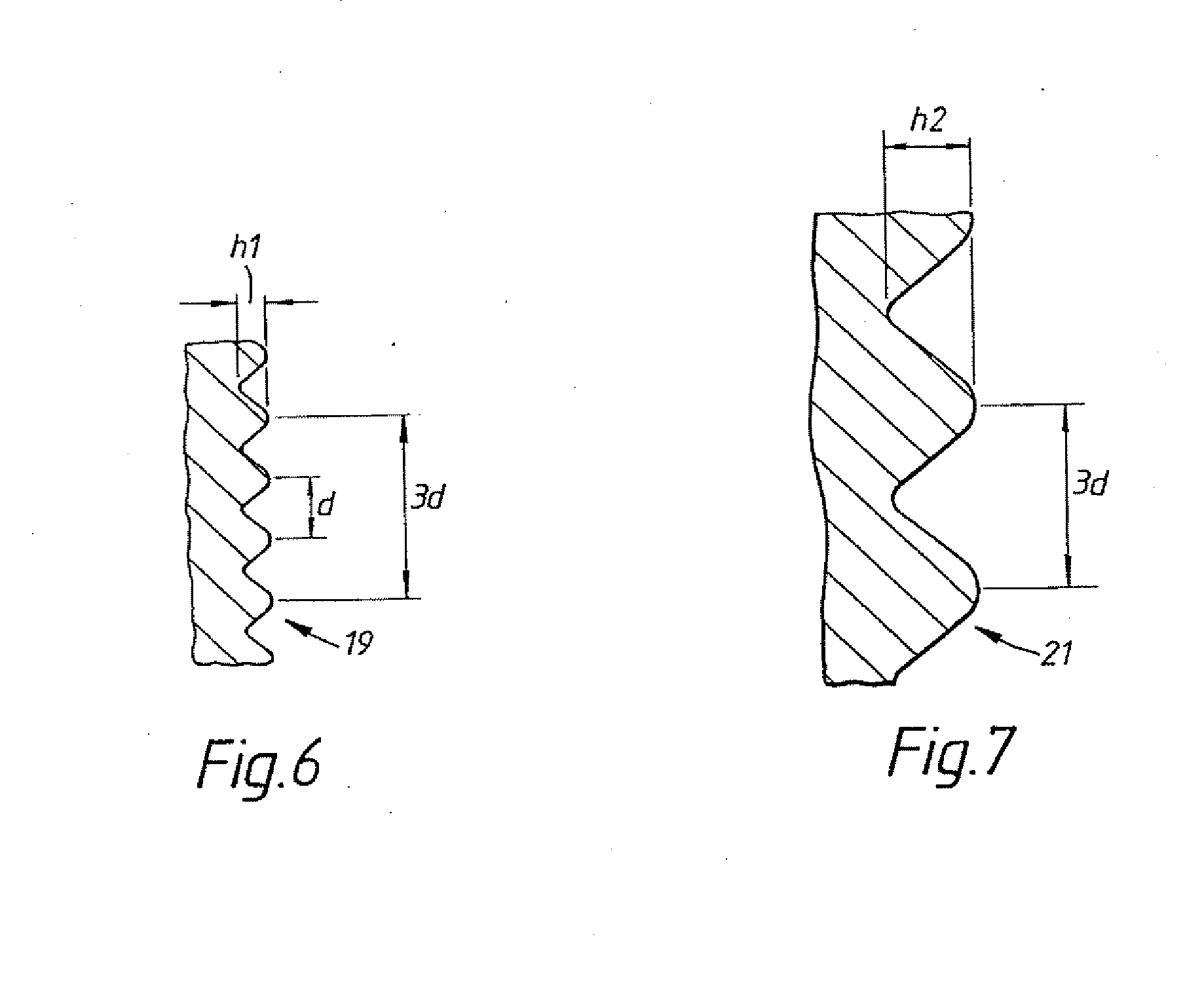

[0042] Referring to FIG. 1, the implant 10 has an apical end 1 which is presented by a first conical section 3 to ease insertion of the implant 10 into the bore-hole, a coronal end 5 presented by a second conical section 6 and an intermediate section 7 of constant diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com