Method and apparatus for controlling a switchable cam follower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

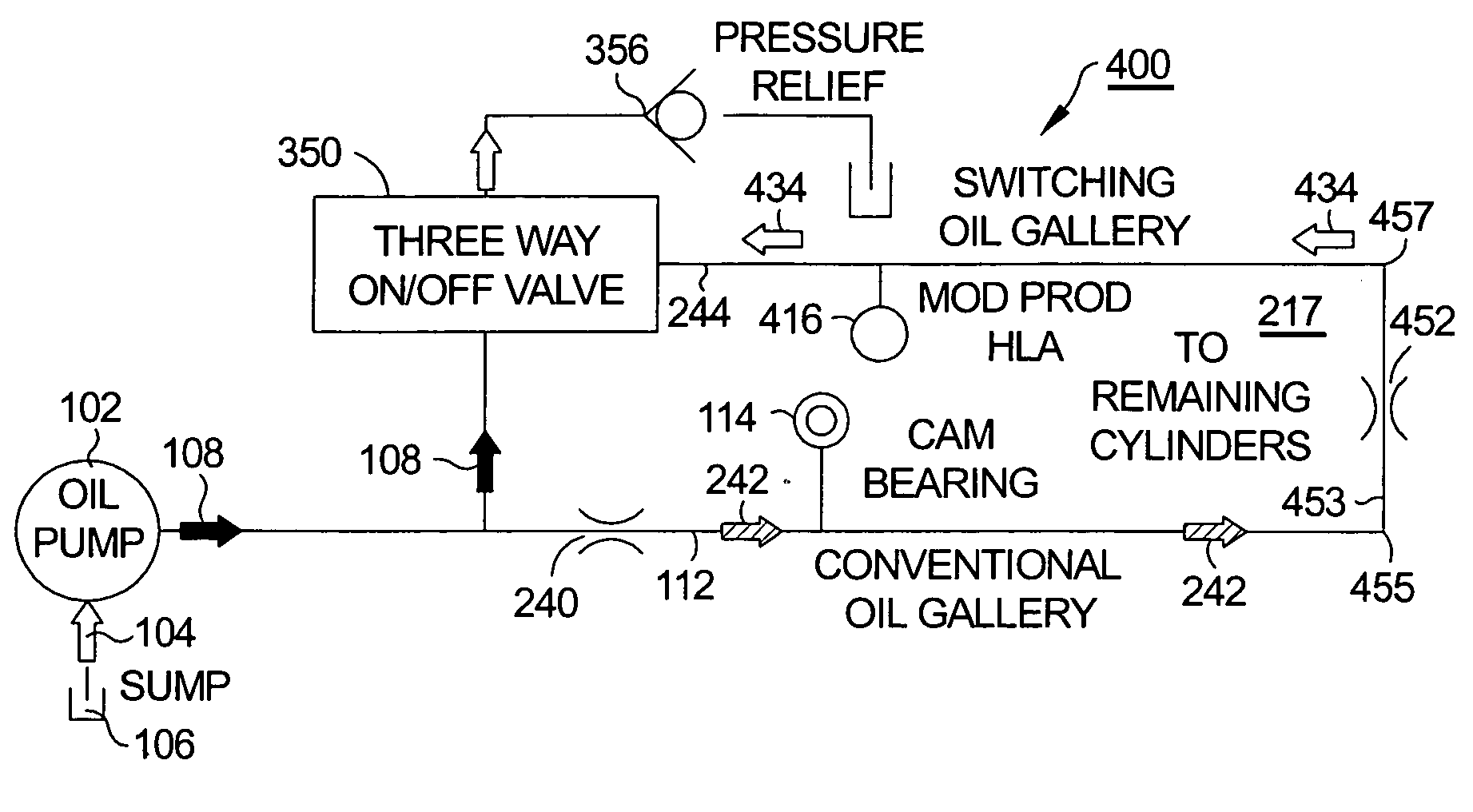

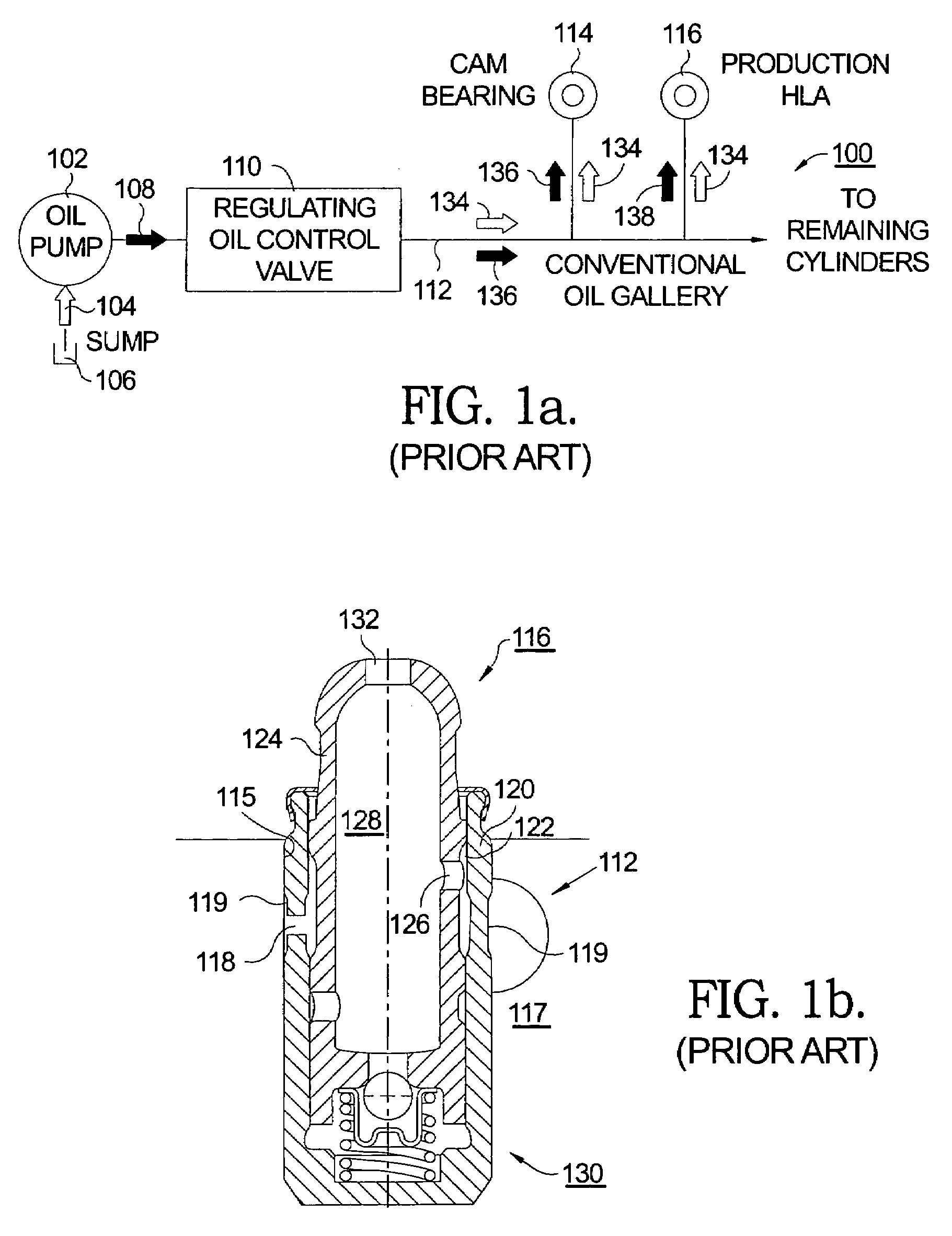

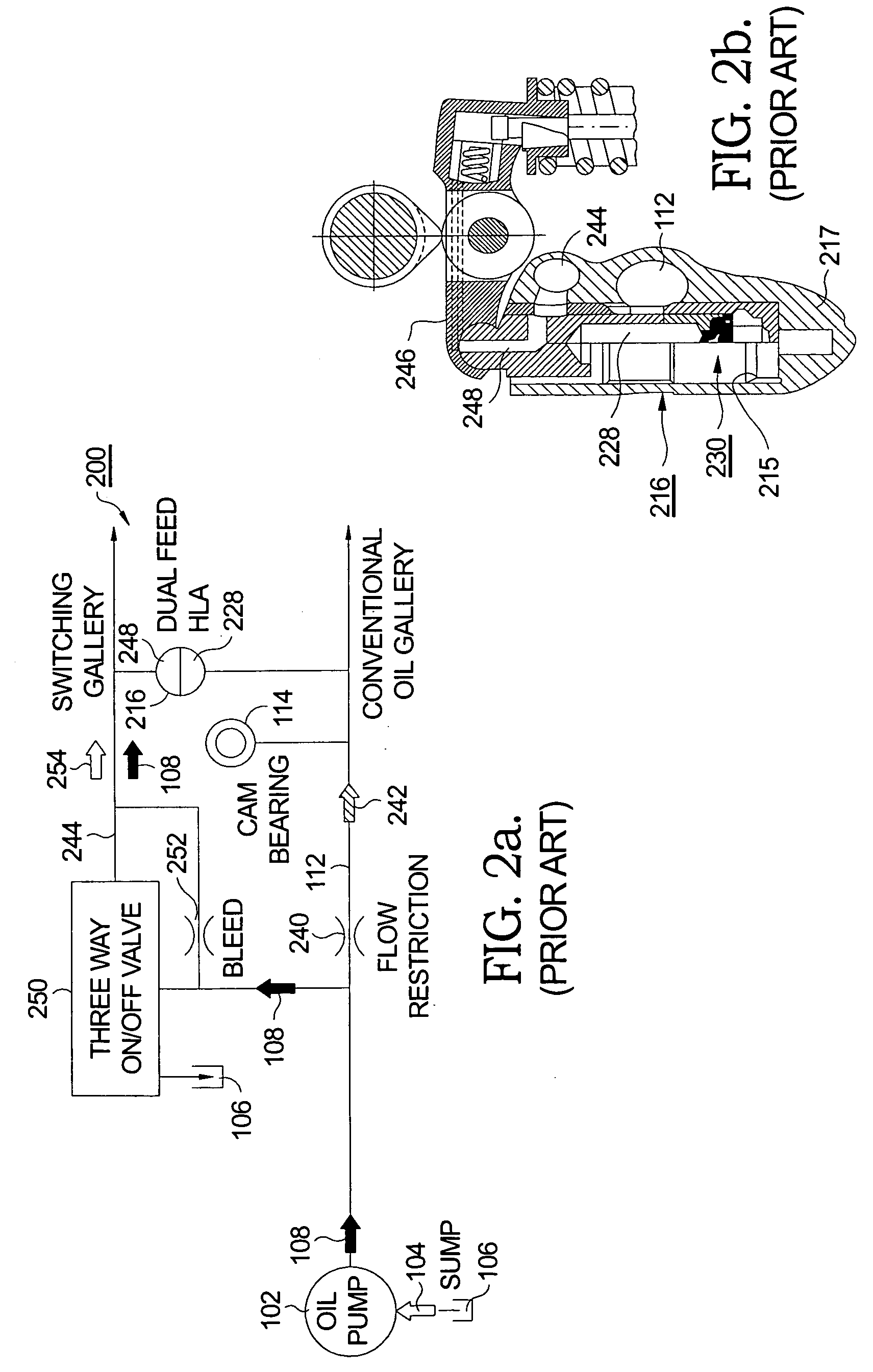

[0024]The advantages and benefits of an oil supply system in accordance with the invention may be better appreciated by first considering three prior art systems.

[0025]Referring to FIGS. 1a and 1b, a first prior art oil supply system 100 includes a pressurizing pump 102 which draws intake hydraulic fluid 104 from a sump 106. Fluid 104 is typically engine oil and sump 106 is typically an engine crankcase. Pressurized output oil 108 from pump 102 is directed through a regulating oil control valve (ROCV) 110 which regulates pressure in a conventional oil gallery 112 to about 0.5 bar. Pressurized oil is supplied from gallery 112 to cam bearings 114 and to a conventional hydraulic lash adjuster 116 disposed rotatably about its axis in a residence bore 115 in an engine head 117. Oil enters HLA 116 through a first port 118 in HLA body 120, thence into an inner annular groove 122 formed in plunger 124, thence through a second port 126 in plunger 124 which opens into a low-pressure reservoir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com