Carry Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

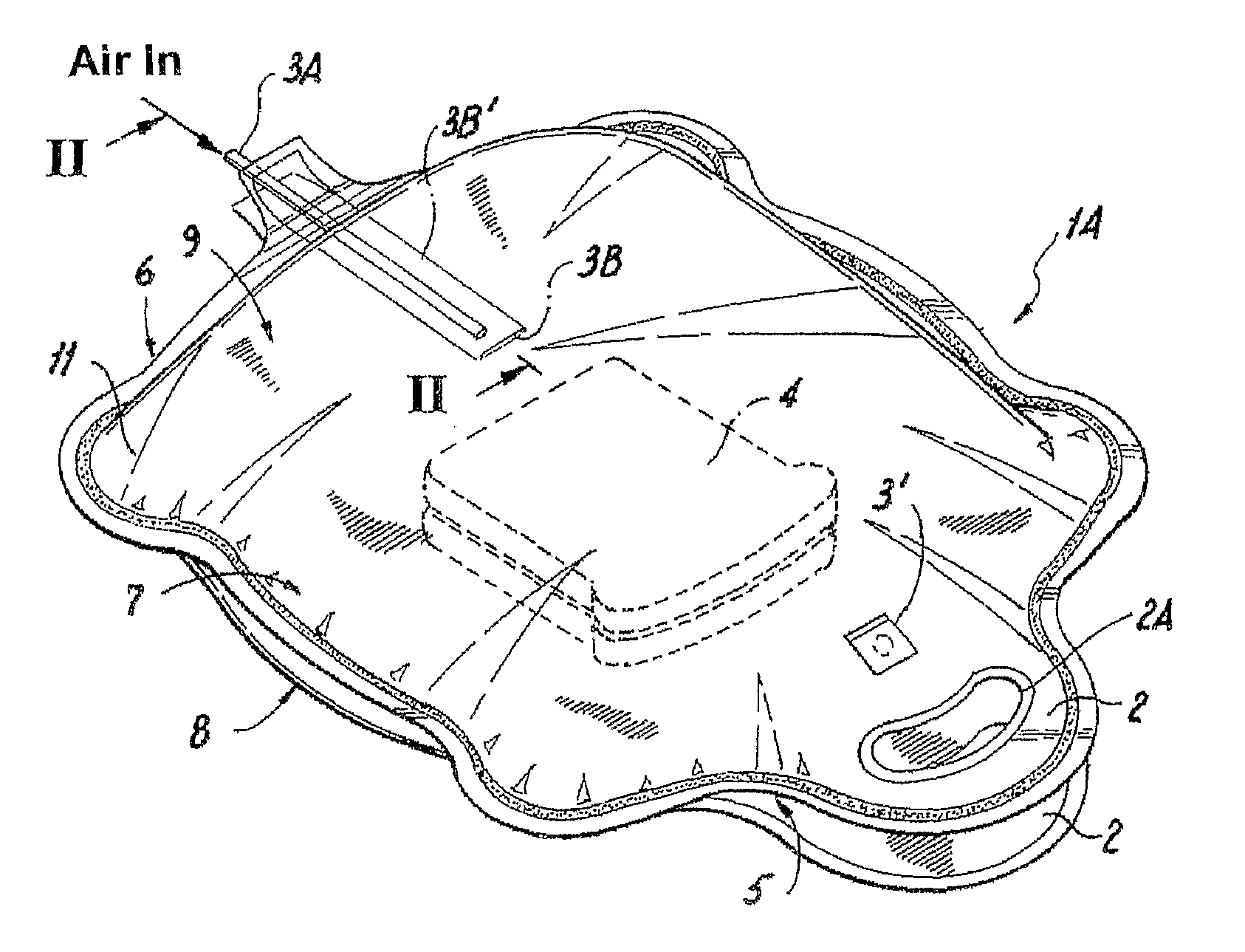

[0096]Referring now to FIGS. 7 through 12, a carry assembly 1A is provided including a pair of separable carry handles 2, having holes 2A providing easy access to a defined inner opening 5 for receiving carry items 4 (here food items) into an inner pouch member (shown later).

[0097]Top and bottom members 7, 8 form an outer surface of an outer pouch 10 having an outer perimeter 6 proximate seam 6′. An inflation access port 3 and deflation access port 3′ provides ready access to at least one access cavity 200 defined between outer pouch 10 and the inner pouch member 9 having inner pouch walls 9′ and 9″. During use, a user inserts items 4 (shown as a sandwich) in direction A into inner opening 5 and blows into access port 3 via a straw 3A filling the bounded cavity 200 with air along air flows 9B to a desired inflation pressure, causing outer pouch 10 of carry assembly 1A to expand and assume a shape defined by outer seals 6′ and outer perimeter 6. Such a shape and pressure provides sec...

third embodiment

[0109]As noted in the third embodiment, inner pouch 9A extends substantially to outer perimeter 6 and outer seam 6′ enabling a very simplified and speedy construction and dividing and bisecting the inner region of outer pouch 10C into substantially two halves. As noted in FIG. 17, a bottom portion of inner pouch side walls 9C′, 9C″ proximate inflation portal 3, are in a sealing connection and are not open to the inner pouch opening. An air passage hole 9″ is punched through this sealed connection region allowing air passage between both sides of the inner region of outer pouch 10C without causing deflation into inner pouch 9C.

[0110]In the embodiment shown construction may be substantially simplified while retaining the benefits inherent in the present invention in an alternative embodiment. As described, the present carry device 1C includes four sheets of seamed material and improves both the stability of carry device 1C while improving appearance to a select segment of the market f...

sixth embodiment

[0118]In this sixth embodiment of carry device 1F, inner pouch member is retained on position between two opposing end fixture regions, namely handles 2F / opening 5F, and the region near inflation port 3F. Thus, the present embodiment securely positions inner pouch member 9F in a manner that does not restrain the planer surfaces of inner pouch side walls 9F, 9F′ and retains inner pouch member 9F distant from outer side walls 7F, 8F during inflation, thereby increasing cushioning while allowing inner pouch member 9F to readily adapt to an item to be carried without irregular pressure concentrations along its outer surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com