Hollow core floor and deck element

a technology of hollow core and floor, applied in the direction of bridges, bridge structural details, ceilings, etc., can solve the problem of inhibiting the use of hollow core panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

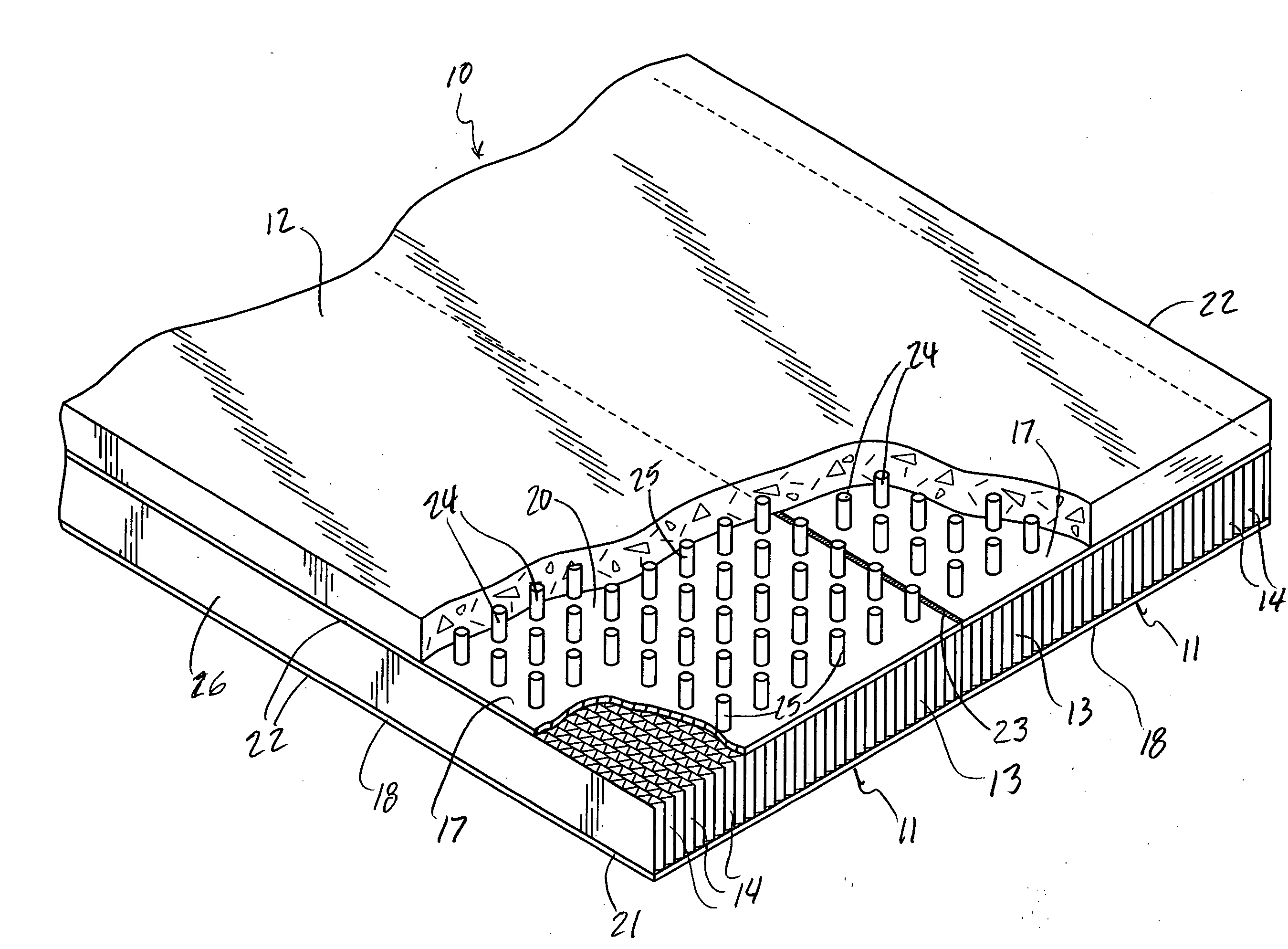

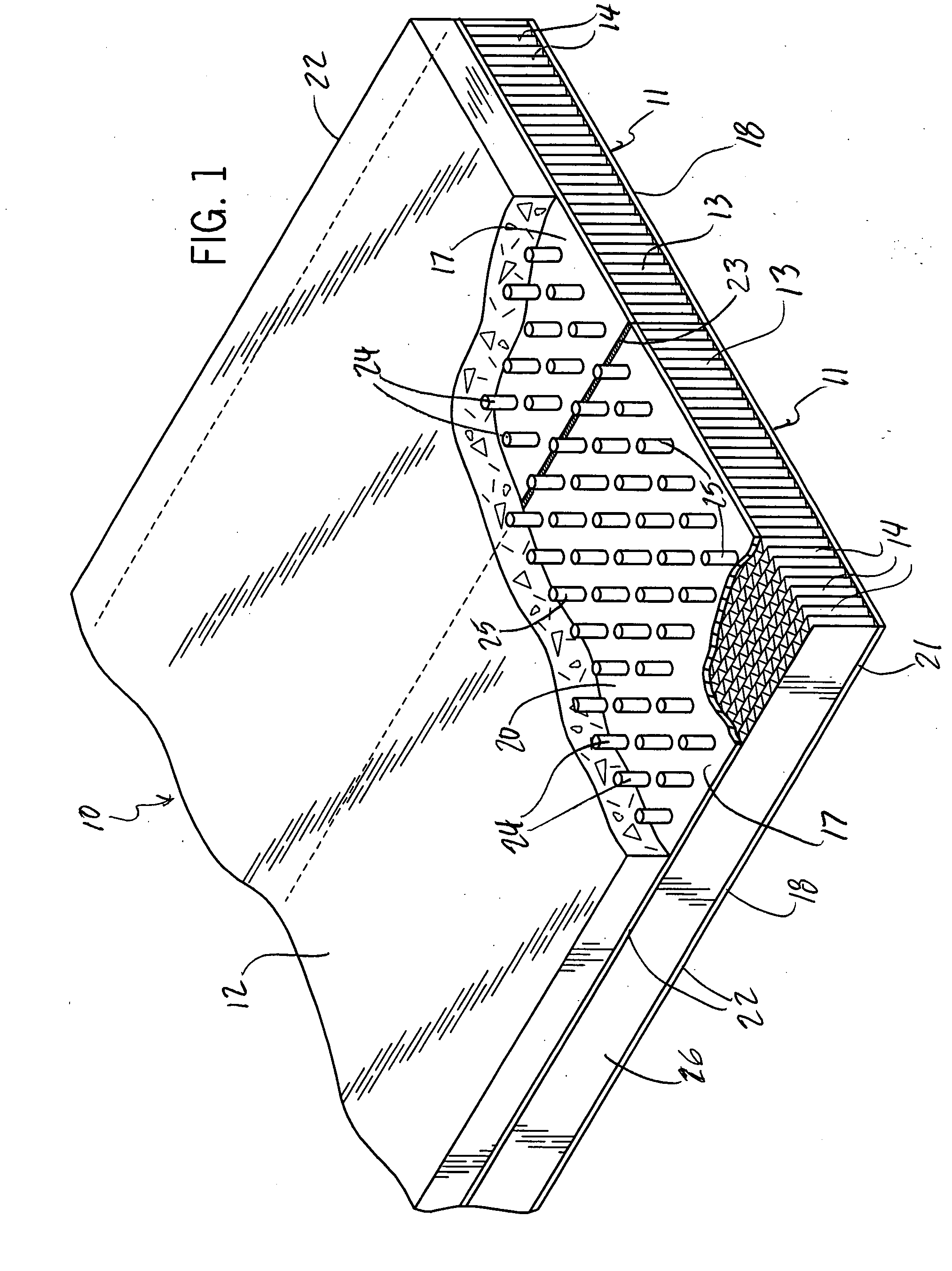

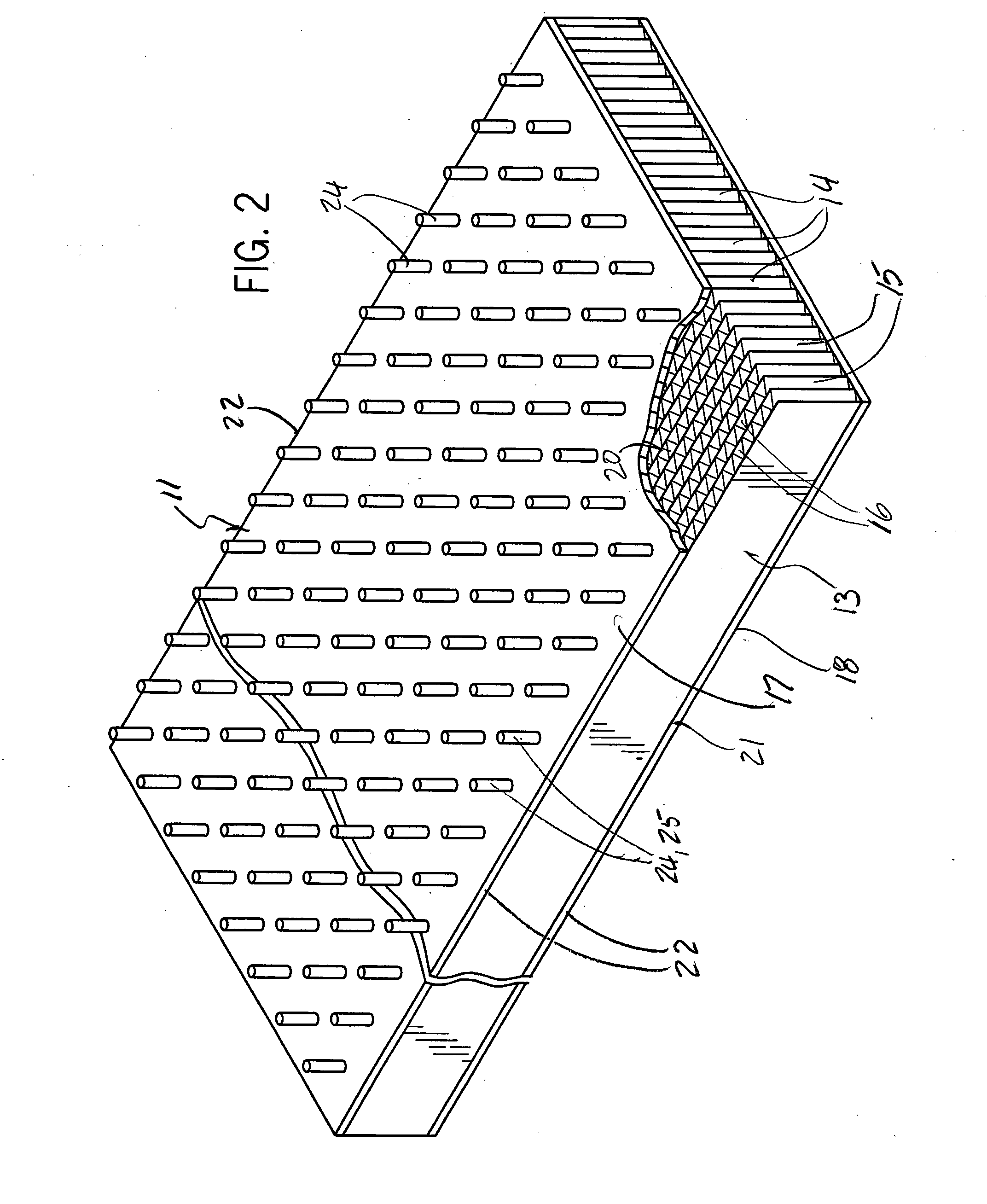

[0010]Referring first to FIG. 1, there is shown a portion of a deck 10 or floor useful, for example, in the construction of a bridge or a building, in which a series of long and relatively narrow modules 11 are joined together and covered with a poured concrete slab 12. Each of the modules 11 could be made of any desired dimensions, but for use in a floor deck, for example, module 11 could have a depth or thickness of 16 in., a width of 8 ft. and a length of 50 ft. To fabricate a deck 10 50 ft. long and 64 ft. wide, eight modules 11 would be joined along their long edges, as partly shown in FIG. 1.

[0011]Each deck module 11 includes a hollow core element 13 of the type described and manufactured in accordance with the method disclosed in my above identified patent application. The hollow core element 13 includes a stack of long, narrow corrugated paperboard strips 14, each of which in the embodiment shown comprises a fluted web 15 and a smooth web 16 joined with a suitable adhesive. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com