Semiconductor light emitting device

a light-emitting device and semiconductor technology, applied in the direction of lasers, optical resonator shape and construction, semiconductor lasers, etc., can solve the problems of unnecessarily complicated fabrication process, and inability to meet the needs of electrical conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following description refers to exemplary embodiments of a semiconductor light emitting assembly according to the present invention. Reference is made in the description to the accompanying drawings whereby the semiconductor light emitting assembly is illustrated in the exemplary embodiments. Similar components between the drawings are identified by the same reference numerals.

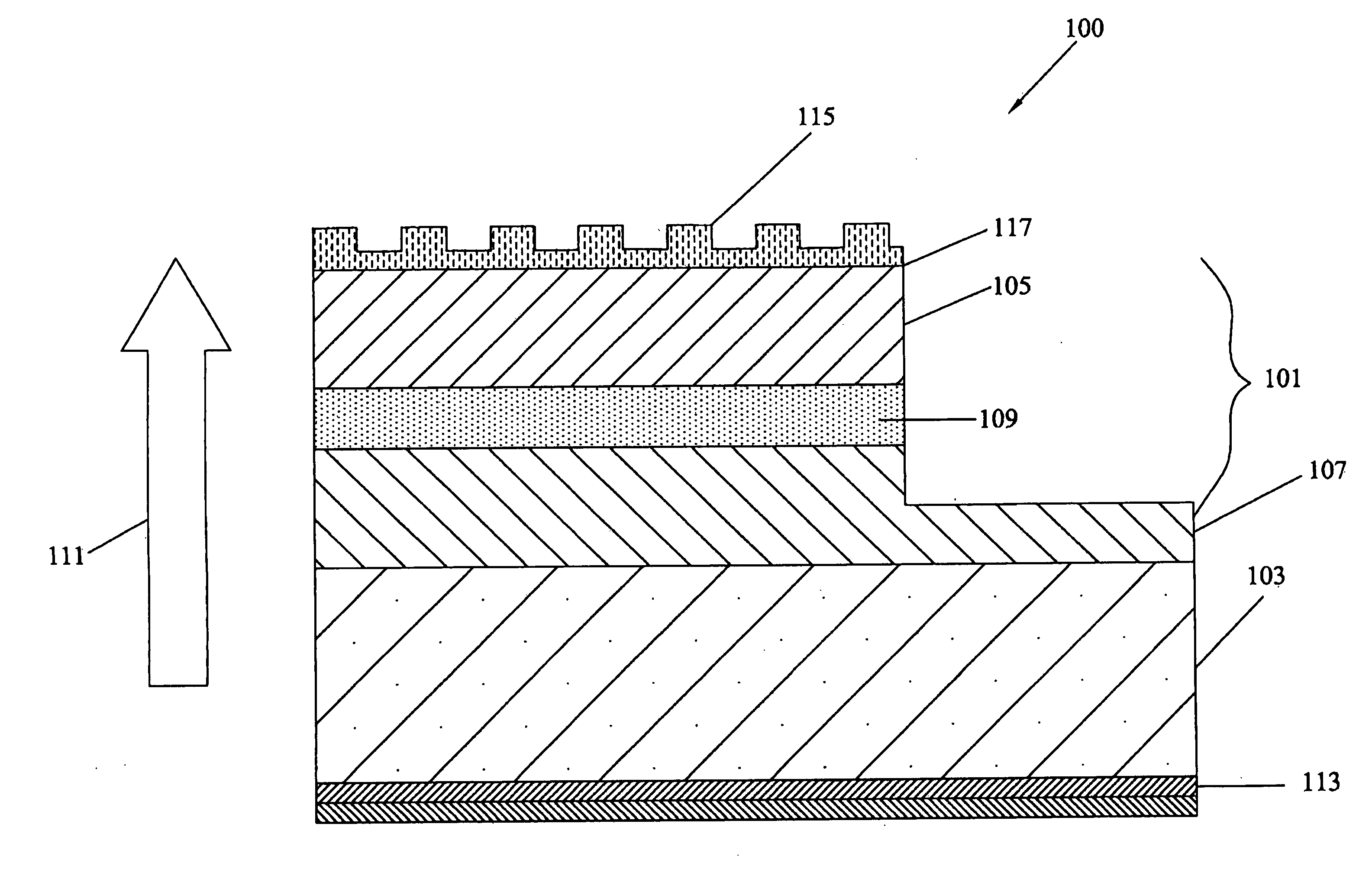

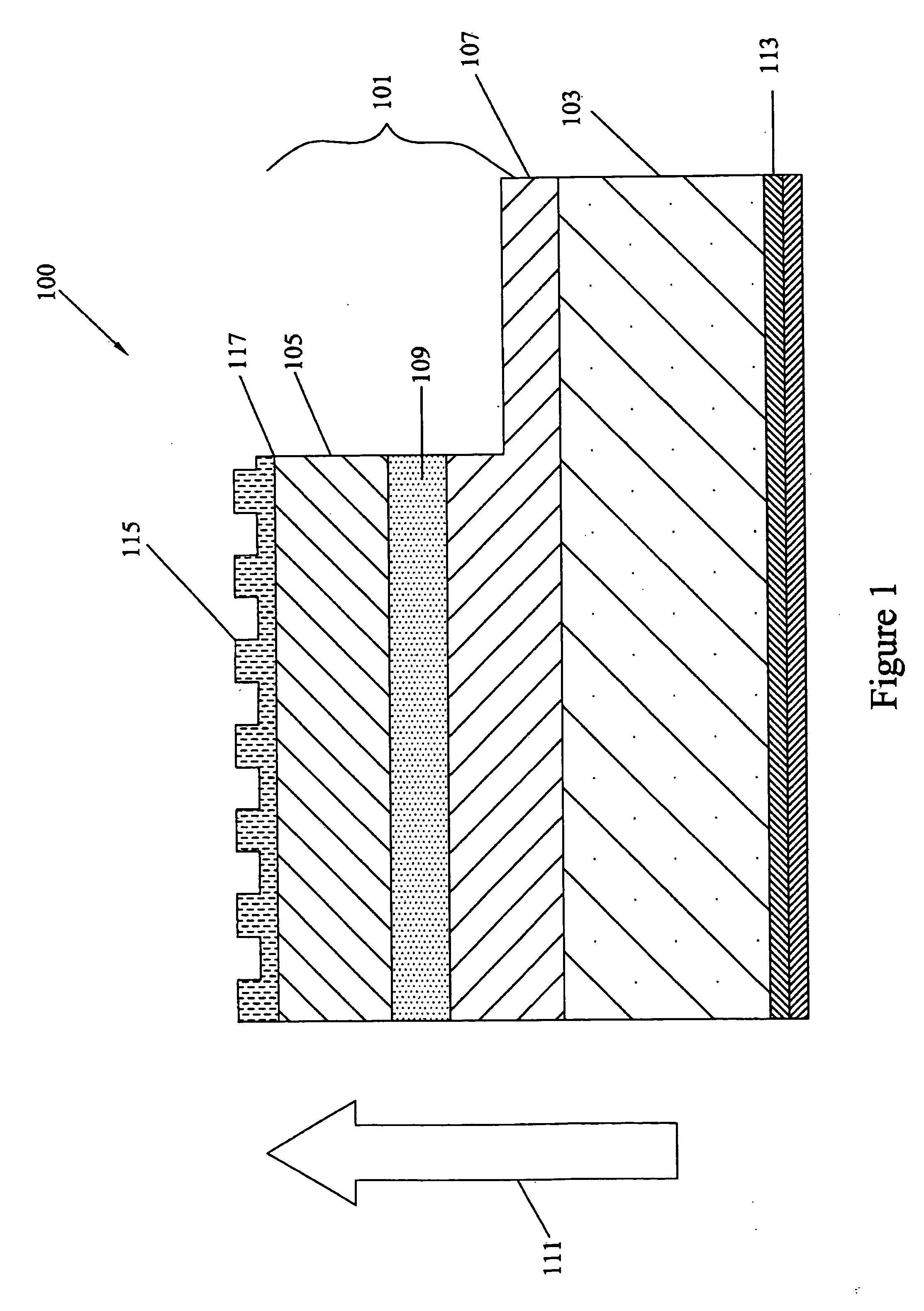

[0029]In FIG. 1, an exemplary embodiment of a top-emitting semiconductor light emitting device 100 includes a multi-layer stack 101 of materials formed on a substrate 103; the multi-layer stack 101 includes a layer of p-doped material or p-type semiconductor layer 105, a layer of n-doped material or an n-type semiconductor layer 107, and a light generating region or p-n junction 109 as generally understood in the art. When powered, the p-n junction 109 emits lights in all directions, but a primary amount of light emissions will exit the top-emitting semiconductor light emitting device 100 in a primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com