Lubricating oil feeding mechanism in a swash type compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

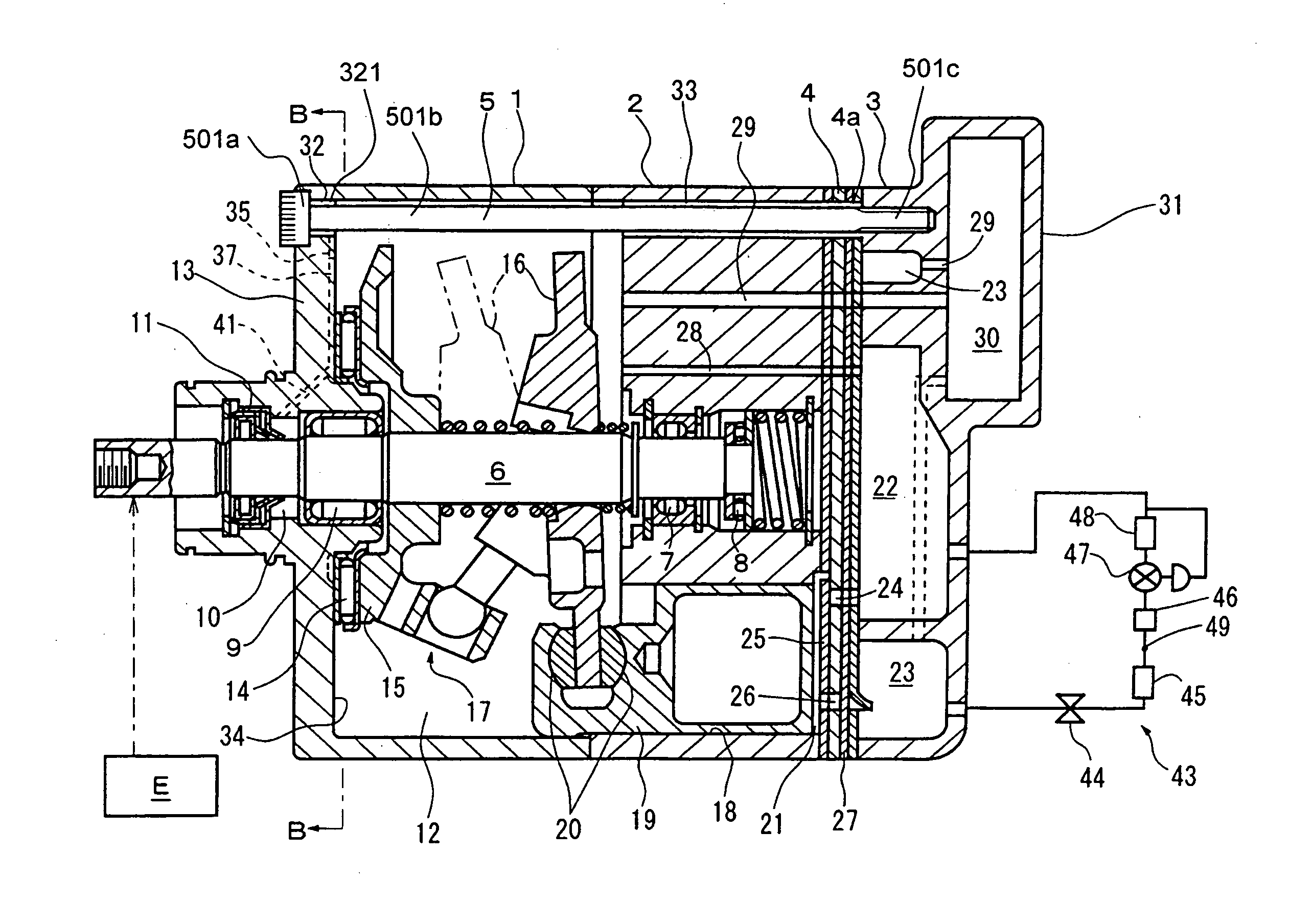

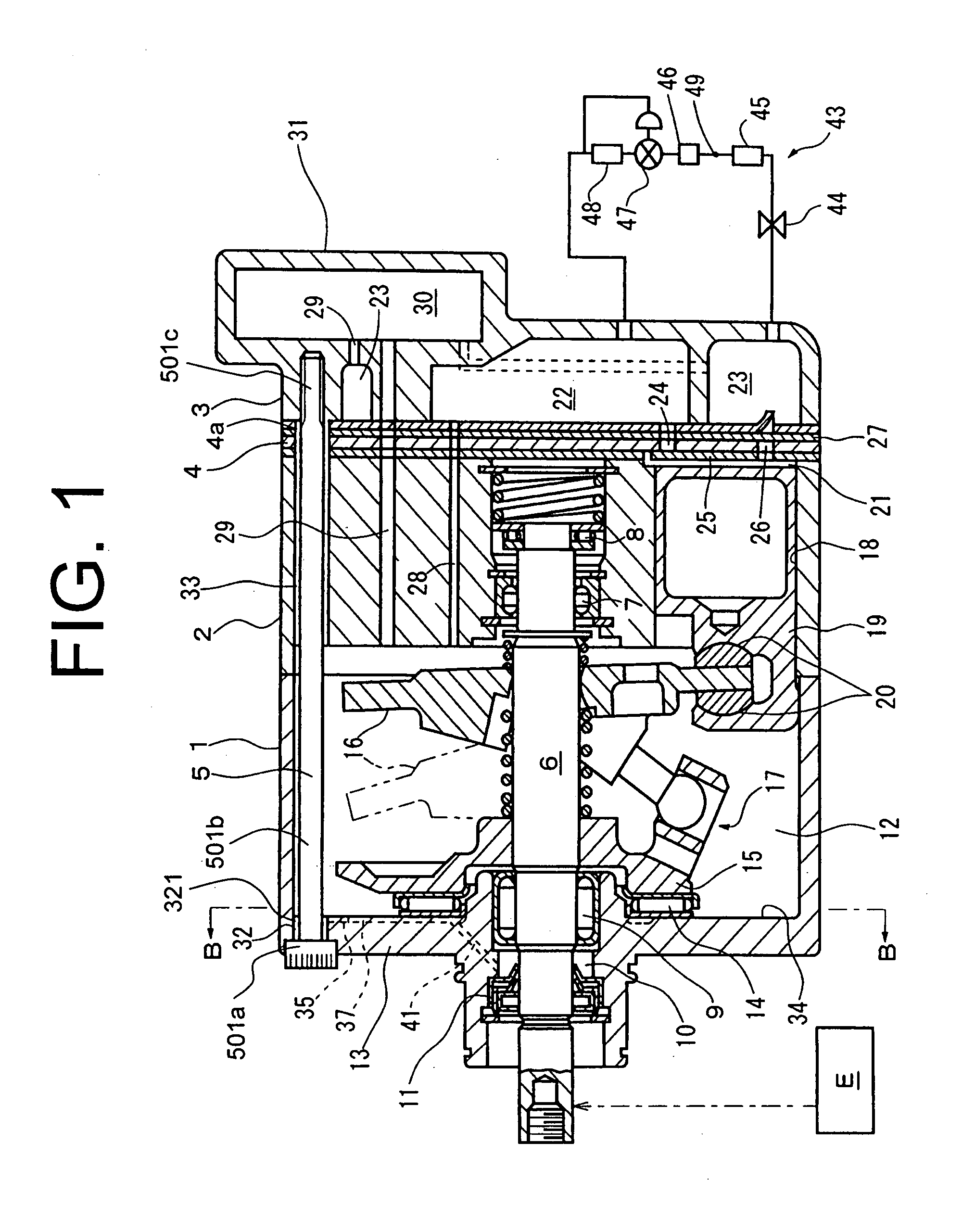

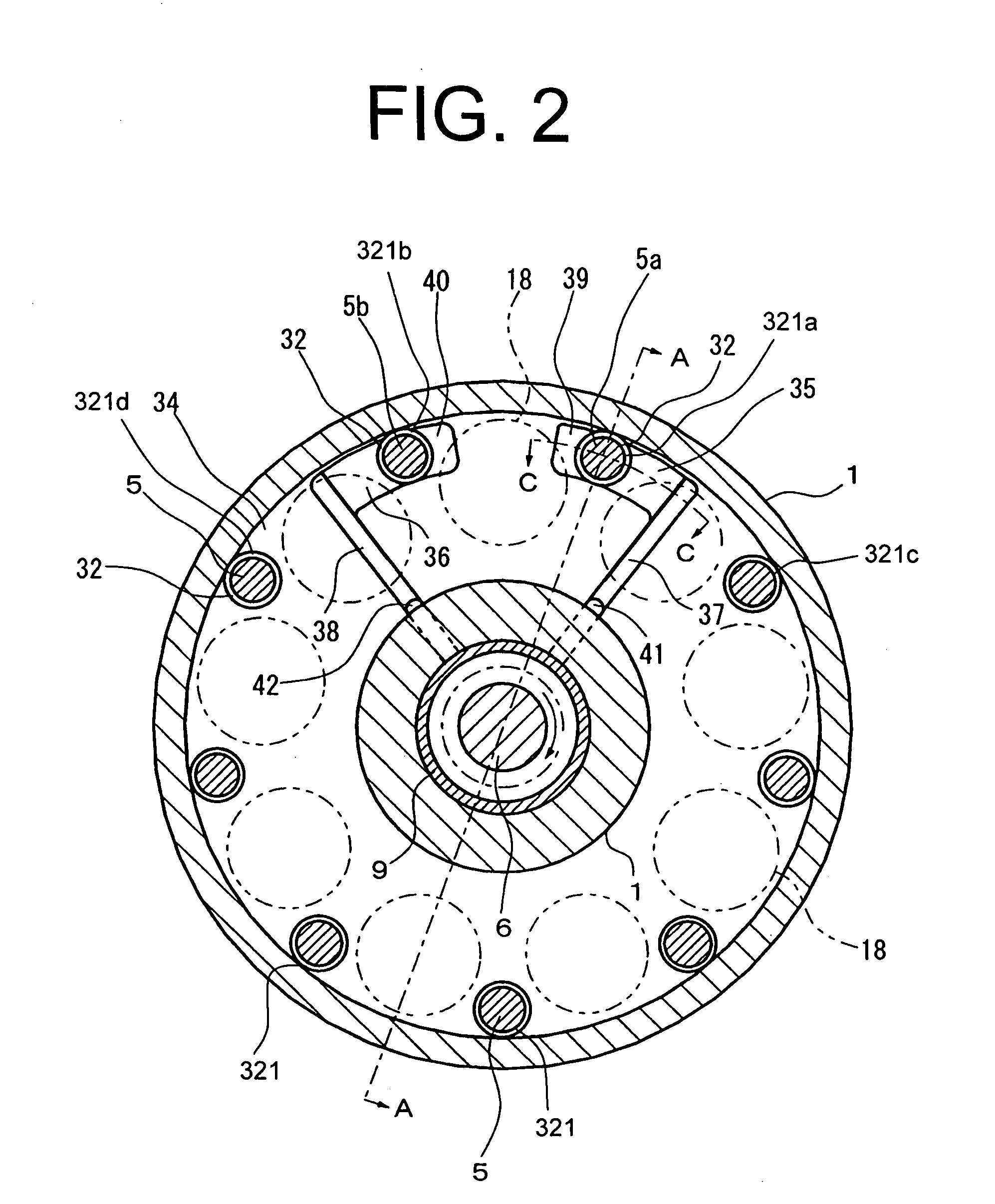

[0021]Referring to FIGS. 1, 2 and 3, the present invention is described hereinafter. FIG. 1 shows a variable displacement swash plate type compressor whose housing comprises a front housing 1, a cylinder block 2, a rear housing 3 and a valve plate unit 4 interposed between the cylinder block 2 and the rear housing 3. These housing elements 1, 2, 3 and 4 are fastened together as one body with a plurality (nine) of bolts 5 as shown in FIG. 2. The front housing 1 and the cylinder block 2 define a swash plate chamber 12 as a control chamber therebetween.

[0022]The front housing 1 and cylinder block 2 have a central axial bore formed therein respectively for receiving a drive shaft 6 which is rotatably supported by a pair of radial bearings 7 and 9 provided in the central axial bore, wherein one end of which is further supported by a thrust bearing 8 provided in the central axial bore of the cylinder block 2. Furthermore, in the central axial bore, a shaft seal 11 is disposed between the ...

second embodiment

[0051]Since stress concentration is likely to take place around the first bore 32 under strong fastening power by the bolts 5, in this case, it may be difficult in view of the strength required for the front housing 1 that an oil-collecting recess 50 is formed being connected to all around the circumference of the first bore 32 with a cutting process. however, the connection groove 51 connected with the first bore 32 is arranged narrower than the diameter of the first bore 32. Therefore, the stress concentration to be generated around the first bore 32 can be reduced.

[0052]FIG. 5 shows a lubricating oil feeding mechanism according to a third embodiment. In the third embodiment, component parts and elements corresponding to those of the above first embodiment are indicated by identical reference numerals, and a description thereof is omitted. What is different from the first embodiment is that a sub oil-collecting recess 54 extends over two of the gaps 321a, 321b to connect the gap ...

fourth embodiment

[0064]In the fourth embodiment, in addition to the lubricating oil feeding mechanism described before, a first sub oil-collecting recess connects the gap 321b to a gap 321d which is in the upper position with respect to the shaft seal 11 as sliding part to be lubricated in the housing in an operating state of the mounted compressor. Also, a second sub oil-collecting recess is connected to the gap 321b, and an oil-collecting recess is connected to the gap 321d, the oil-collecting recess being connected to an oil-supplying groove. Although both of those mechanism are adopted together so as to collect lubricating oil gathered in the gaps 321a, 321b, 321c and 321d, only one of the described mechanism might be used to improve the lubricativity.

[0065]In the fourth embodiment, the oil-supplying groove 58 is connected to the sub oil-collecting recess 56. In this embodiment, the sub oil-collecting recess 56 represents an oil-collecting recess, and the oil-collecting recess 55 represents a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com